Preparation method of polyethylene nucleating agent

A nucleating agent, polyethylene technology, applied in the field of preparation of new polyethylene nucleating agent, can solve the problems affecting the application of polyethylene materials, warping deformation, large shrinkage rate, etc., achieve high crystallinity, easy molding and cooling, The effect of high crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

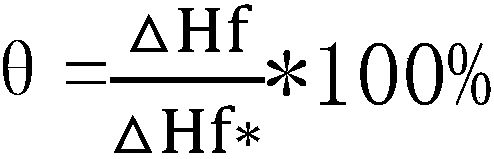

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Put 2mmol of 1,3 propylenediamine and 1.2mmol of phenylurea into a round bottom flask, then add 15mL of dioxane, under the protection of nitrogen, reflux at 110°C for 18h, after the reaction is completed, cool to room temperature; after adding 12 mL of ethyl acetate to the flask, wash it 4 times with HCl with a concentration of 1.0 mol / L, the amount of HCl is 50 mL / time, and the organic layer after standing and layering is dried with anhydrous sodium sulfate and spin Steam, and then recrystallize the solid product after rotary steaming with methanol to obtain the final product.

Embodiment 2

[0017] Put 2mmol of 1,3 propylenediamine and 1.0mmol of phenylurea into a round bottom flask, add 18mL of dioxane, under the protection of nitrogen, carry out a reflux reaction at 105°C for 16h, after the reaction is completed, cool to room temperature, and pour Add 10mL ethyl acetate to the flask, and wash it with 1.2mol / L HCl for 3 times. The amount of HCl is 45mL / time. The final solid product was then recrystallized with methanol to obtain the final product.

Embodiment 3

[0019] Put 2mmol of 1,3 propylenediamine and 1.3mmol of phenylurea into a round bottom flask, add 12mL of dioxane, under the protection of nitrogen, carry out reflux reaction at 115°C for 17h, after the reaction is completed, cool to room temperature , add 12mL ethyl acetate to the flask, and wash it with 1.3mol / L HCl for 4 times. Recrystallization to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com