A process method for surface treatment of electrolytic copper foil and the treated copper foil

A technology of electrolytic copper foil and process method, which is applied in the field of electrolytic copper foil treatment process, can solve the problems of small composition control range, complex production process, complex process steps, etc., achieve high oxidation resistance, simplify production process, and excellent anti-stripping The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

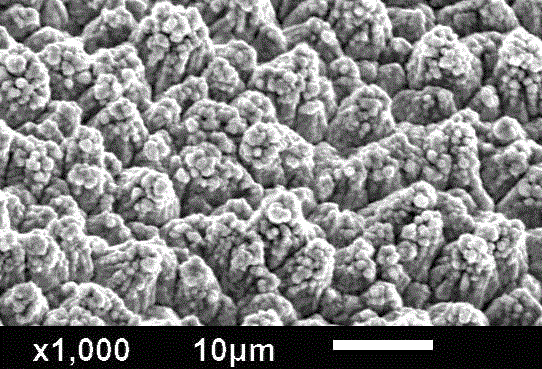

Embodiment 1

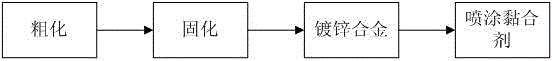

[0024] The one-time surface treatment process of 18um thick electrolytic copper foil, the specific process is as follows:

[0025] l. Preparation of roughening solution: mix and dissolve cathode copper, sulfuric acid, and soft water to generate copper sulfate solution, then add surface active substance additive A to the copper sulfate solution, mix well and then enter the roughening tank for electroplating. Contains: 10-30 grams of copper, 80-200 grams of sulfuric acid, 5-50 mg of surface active substance additive A, the temperature is 25°C, the surface active substance additive A is rare earth, and the roughening current density is 25-40A / dm2;

[0026] 2. Preparation of curing solution: mix and dissolve cathode copper, sulfuric acid and soft water to generate copper sulfate solution, enter the curing tank for electroplating, and each liter of curing solution contains: 50-100 grams of copper, 80-200 grams of sulfuric acid, and the temperature is 35 ° C. Curing current density ...

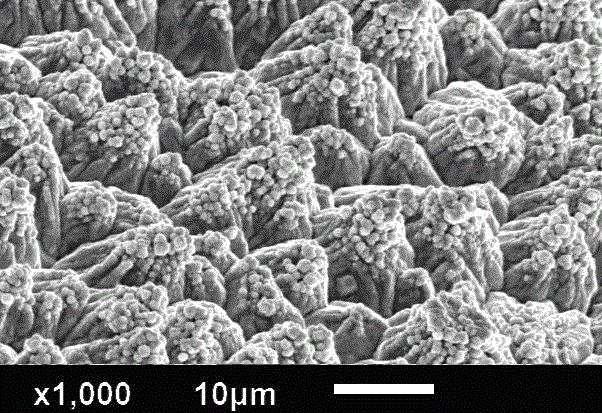

Embodiment 2

[0033] The one-time surface treatment process of 35um thick electrolytic copper foil, the specific process is as follows:

[0034] l. Preparation of roughening solution: mix and dissolve cathode copper, sulfuric acid, and soft water to generate copper sulfate solution, then add surface active substance additive A to the copper sulfate solution, mix well and then enter the roughening tank for electroplating. Contains: copper 15-25 grams, sulfuric acid 100-170 grams, surface active substance additive A 10-35 mg, electroplating temperature is 50 ℃, additive A is gelatin, hydroxyethyl cellulose, benzotriazole, gum arabic, arsenic Acid, a kind of rare earth, coarsening current density 25-40A / dm2;;

[0035] 2. Preparation of curing solution: Mix and dissolve cathode copper, sulfuric acid and soft water to generate copper sulfate solution, enter the curing tank for electroplating, each liter of curing solution contains: 60-80 grams of copper, 90-180 grams of sulfuric acid, and the pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com