Preparation method of aqueous polyurethane butyronitrile resin

A technology of polyurethane nitrile butadiene and water-based polyurethane is applied in the field of preparation of outdoor coatings for road users, and can solve the problems of low hydrolysis resistance of water-based polyurethane and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

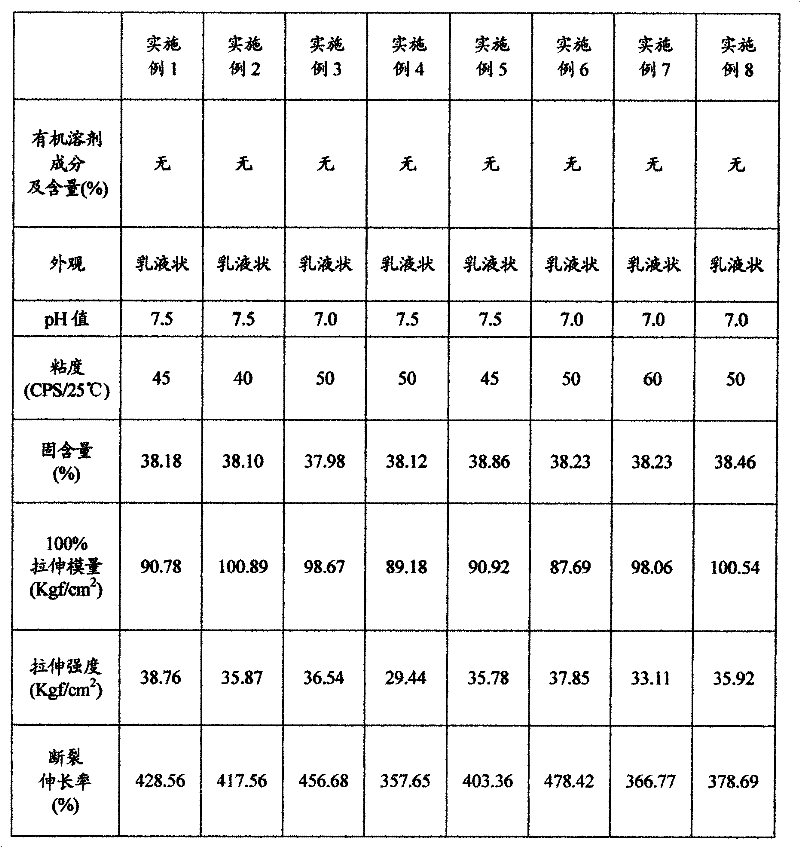

Examples

preparation example Construction

[0018] The preparation method of this waterborne polyurethane nitrile resin comprises the following steps:

[0019] (1) Prepare polyurethane prepolymer:

[0020] (1) Vacuum dehydrate the macromolecular polyol at 85-120°C for half an hour, cool down to below 50°C, add polyisocyanate monomer, heat up to 75-95°C and react for 1-5 hours;

[0021] (2) Cool the material obtained in step (1) to 50°C, add a hydrophilic compound and a chain extender to the reaction system, and add a solvent to adjust the viscosity to 2000-4000cps, then raise the temperature to 70-85°C and continue the reflux reaction for 1- 5 hours, during the reaction process, add solvent appropriately to adjust the viscosity to 4000-8000cps, add hydroxyacrylate, continue the reflux reaction for 1-3 hours, and the reaction temperature is 70-75°C to obtain a polyurethane prepolymer;

[0022] (2) Prepare water-based polyurethane emulsion:

[0023] (1) Add the polyurethane prepolymer prepared in step (1) into a reactio...

Embodiment 1

[0040] (1) Add 200g polycarbonate diol (M W =2000), heated to 120°C, dehydrated in vacuum for half an hour, added 123.14g of dicyclohexyl diisocyanate (H 12 MDI), 0.15g dibutyltin dilaurate (DBTDL), be warming up to 90 ℃ and react for 2 hours, then add 13.5g dimethylolpropionic acid (DMPA), 7.2g1,4 butanediol (BDO), 70ml acetone, React at 80°C for one hour, add 0.15g of dibutyltin dilaurate (DBTDL) and 100g of acetone, react at 75°C for 3 hours, add 10g of hydroxy acrylate, and keep warm for 2 hours.

[0041] (2) Unload the reactants into the dispersing container and stir, cool down to 30°C and add 9.5g of triethylamine, pay attention to controlling the speed of the disperser, add 560g of water, after the emulsion is formed, add 12g of isopropylamine dissolved in 20g of water Phoronediamine (IPDA).

[0042] (three) get butadiene 50g, acrylonitrile 60g (CH 2 =CHCN) mixed evenly to make hydrocarbon phase, take sodium hydroxide (NaOH) 1g, sodium pyrophosphate (NaOH) 4 P 2 o ...

Embodiment 2

[0044] (1) Add 200g polycarbonate dibasic alcohol (M W =2000), heated to 120°C, dehydrated in vacuum for half an hour, added 123.14g of dicyclohexyl diisocyanate (H 12 MDI), 0.15g dibutyltin dilaurate (DBTDL), heated to 90°C for 2 hours, then added 13.5g dimethylolpropionic acid (DMPA), 7.2g 1,4 butanediol (BDO), 0.7g three Methylolpropane, 70ml acetone, react at 80°C for one hour, add 0.15g dibutyltin dilaurate (DBTDL) and 100g acetone, react at 75°C for 3 hours. Add 10 g of hydroxy acrylate, and keep the reaction for 2 hours.

[0045] (2) Unload the reactants into the dispersing container and stir, cool down to 30°C and add 9.5g of triethylamine, pay attention to controlling the speed of the disperser, add 560g of water, after the emulsion is formed, add 12g of isopropylamine dissolved in 20g of water Phoronediamine (IPDA).

[0046] (three) get butadiene 50g, acrylonitrile 60g (CH 2 =CHCN) mixed evenly to make hydrocarbon phase, take sodium hydroxide (NaOH) 1g, sodium py...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com