SMC drain pipe and preparation material and preparation method thereof

The technology of drain pipe and water inlet pipe is applied in the field of SMC drain pipe and its preparation materials and preparation, which can solve the problems of low price, easy leakage, poor interface bonding durability, etc., and achieves low production cost and long service life. , the effect of excellent electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

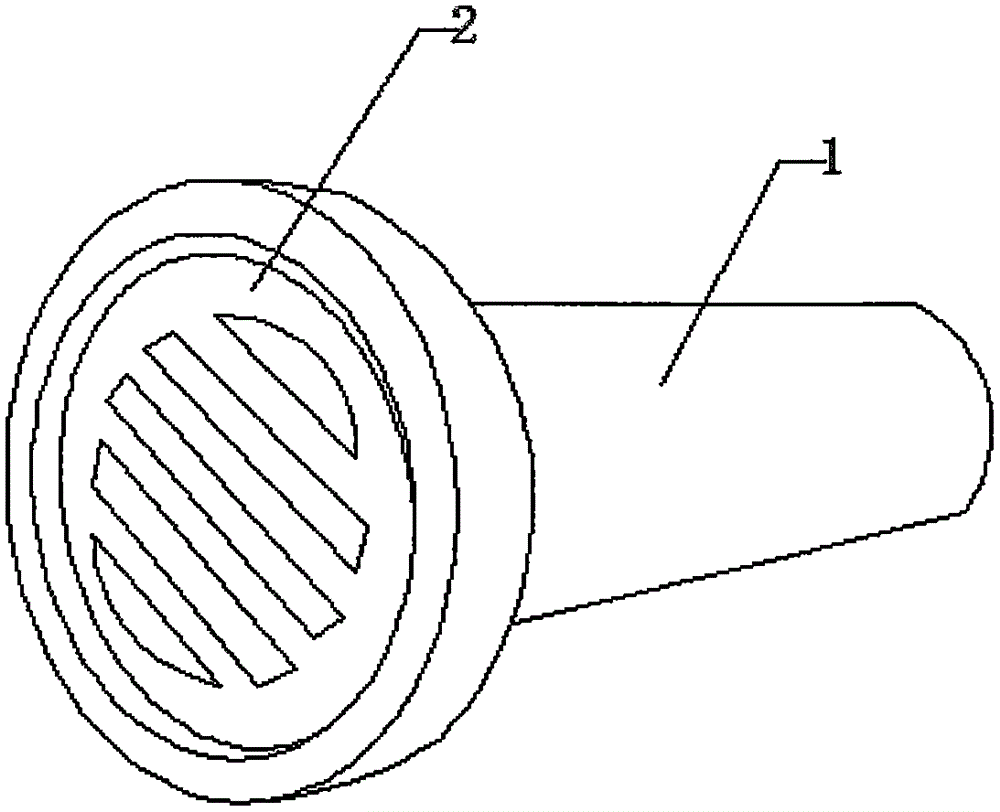

[0025] Such as figure 1 The shown SMC drain pipe includes a water inlet pipe 1 and an anti-blocking cover 2 made of the preparation material of the SMC drain pipe; the anti-blocking cover 2 is embedded in the upper part of the water inlet pipe 1 .

[0026] The preparation material of SMC drainpipe of the present invention, described material is made up of the following material of weight fraction meter: 20%~28% unsaturated polyester resin, 5%~8% chopped coarse glass fiber, 20%~32% medium alkali Glass fiber cloth, 25%~38% filler, 8%~15% industrial waste, 10%~20% glass powder, 0.5%~2.0% internal release agent, 1%~2.8% low shrinkage additive, 0.5%~2.5 % chemical thickener, 0.2% to 1.0% initiator and 0.5% to 4.5% colorant.

[0027] A catalyst is also added to the material; the catalyst is styrene.

[0028] The filler is calcium carbonate, talcum powder or hydrated alumina.

[0029] The low shrinkage additive is PE powder.

[0030] The chemical thickener is calcium oxide.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com