Polyaniline-containing polyaspartate polyurea anti-corrosive paint and preparation method thereof

An aspartate and anti-corrosion coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of short anti-corrosion life, short gel time, short pot life, etc., and achieve chemical corrosion resistance. The effect of excellent performance, excellent corrosion resistance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

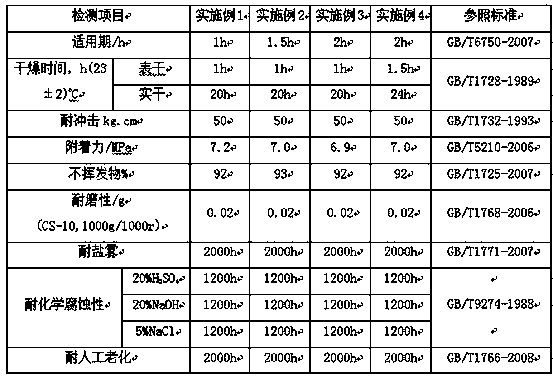

Examples

Embodiment 1

[0027] 1) Preparation of component A: 90g polyaspartate resin F-520, 90g polyaspartate resin F-524, 16g propylene glycol methyl ether acetate, 8g intrinsic state polyaniline, 80g titanium dioxide , 60g mica powder, 40g zinc oxide, 5g organic bentonite, 5g ultraviolet absorber UV-0, 2g defoamer BYK-066N, 2g leveling agent BYK-354 and 2.5g wetting and dispersing agent BYK161, placed in the dispersing machine in turn Internal dispersion, the linear speed of the agitator in the disperser is above 15m / s, after mixing, add glass beads as the grinding medium, use a sand mill to grind to a fineness of ≤40um, filter and pack to obtain component A;

[0028] 2) Component B curing agent: weigh 100g-105g of aliphatic polyisocyanate N-3200 produced by Bayer as component B;

[0029] 3) Stir the above components A and B evenly before use to obtain a polyaniline-containing polyaspartate polyurea anticorrosion coating.

Embodiment 2

[0031] 1) Preparation of component A: 60g polyaspartate resin F-520, 100g polyaspartate resin F-524, 20g propylene glycol methyl ether acetate, 8g intrinsic state polyaniline, 80g titanium dioxide , 15g carbon black, 60g precipitated barium sulfate, 40g mica powder, 5g polyamide wax, 5g ultraviolet absorber UV-9, 2g defoamer BYK-A530, 2g leveling agent BYK-352 and 2.5g wetting and dispersing agent BYK -164, placed in the disperser in order to disperse, the linear speed of the agitator in the disperser is above 15m / s, after mixing, add glass beads as the grinding medium, use a sand mill to grind to a fineness of ≤40um, filter and pack, Get A component;

[0032] 2) Component B curing agent: weigh 85g~90g of aliphatic polyisocyanate N-3600 produced by Bayer Company as component B;

[0033] 3) Stir the above components A and B evenly before use to obtain a polyaniline-containing polyaspartate polyurea anticorrosion coating.

Embodiment 3

[0035] 1) Preparation of component A: 60g polyaspartate resin F-520, 100g polyaspartate resin F-420, 20g propylene glycol methyl ether acetate, 10g intrinsic polyaniline, 90g titanium dioxide , 10g carbon black, 40g zinc oxide, 40g mica powder, 20g precipitated barium sulfate, 5g organic bentonite, 5g ultraviolet absorber UV-24, 2g defoamer BYK-A530, 2g leveling agent BYK-358N and 2.5g wetting Dispersant BYK9077 is placed in the disperser in turn for dispersion. The linear speed of the agitator in the disperser is above 15m / s. After mixing, add glass beads as the grinding medium, use a sand mill to grind to a fineness of ≤40um, filter and pack , get A component;

[0036] 2) Component B curing agent: weigh 85g~90g of aliphatic polyisocyanate N-3200 produced by Bayer Company as component B;

[0037] 3) Stir the above components A and B evenly before use to obtain a polyaniline-containing polyaspartate polyurea anticorrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com