A method for estimating the junction temperature of a power element IGBT in a motor controller

A technology for motor controllers and power components, which is used in thermometers, single semiconductor device testing, instruments, etc. which are directly sensitive to heat electrical/magnetic components. The relationship is not clear and other problems, to achieve the effect of improving the maximum output capability and safety, reducing the cost of components, and simplifying the junction temperature estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The method for estimating the junction temperature of the power element IGBT in the motor controller of the present invention comprises the following steps:

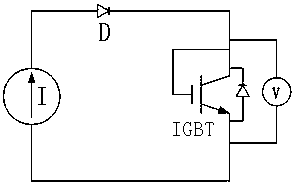

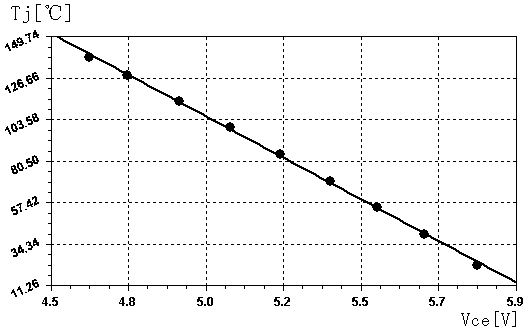

[0044] Step 1, such as figure 1 with figure 2 shown, the IGBT junction temperature T j with saturation voltage drop V ce The relationship curve is extracted, the current source I provides the IGBT current through the diode D, the base of the IGBT is shorted to the collector, and the saturation voltage drop V of the IGBT is measured by the voltage measurement device V ce , the IGBT is placed in the temperature control box, the IGBT is heated by adjusting the temperature of the temperature control box, and the corresponding saturation voltage drop V at different temperatures is recorded ce , fitted to a straight line:

[0045] T j =k×V ce +b (1)

[0046] Among them, k and b are the slope and intercept of the straight line, respectively;

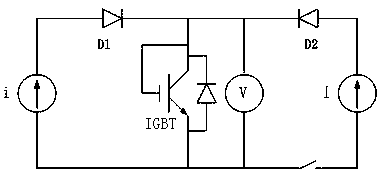

[0047] Step two, such as image 3 with Figure 4 As shown, the extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com