Wide nematic phase mixed liquid crystal material with low threshold value

A technology of mixing liquid crystals and liquid crystal materials, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve problems such as difficult balance of performance parameters, and achieve the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]

[0040] Taking 50g of mixed liquid crystal material as an example to describe its preparation process: use an electronic balance to weigh the following eleven substances:

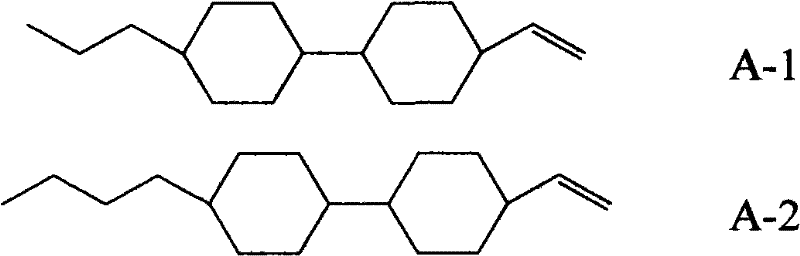

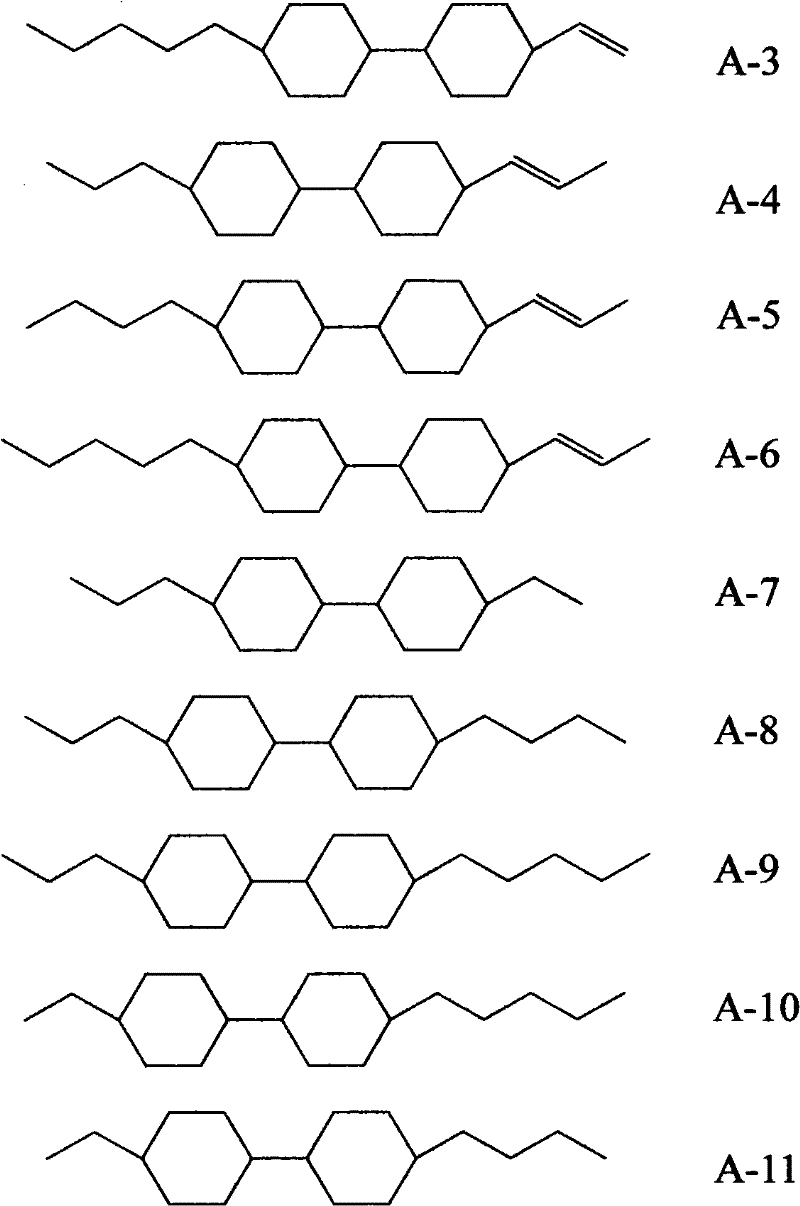

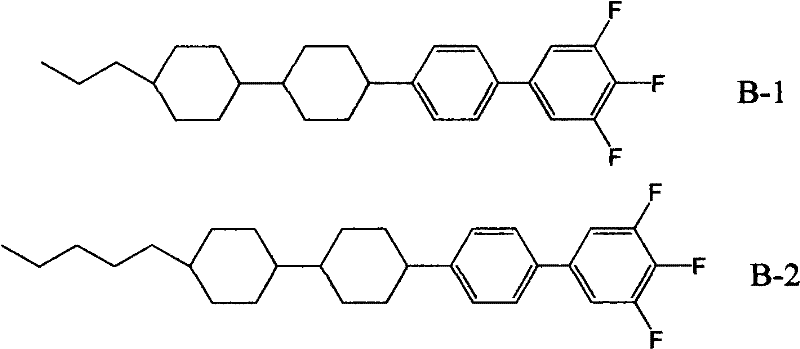

[0041] Monomer liquid crystal

[0042] Put the above eleven substances into a 100ml glass three-necked bottle with magnetic stirring function, under the protection of nitrogen, and under the condition of heating temperature of 50°C, stir while heating, the mixture in the bottle is melted from solid to In liquid state, heat for 3 minutes. When the mixture in the bottle reaches 70°C, keep warm for 30 minutes. After heat preservation, cool down to room temperature naturally to form a milky white opaque nematic mixed liquid crystal material, which is sealed and stored.

Embodiment 2

[0044]

[0045] Take 50g of mixed liquid crystal material as an example to describe its preparation process: Use an electronic balance to weigh the following twelve substances:

[0046] Monomer liquid crystal

[0047] Put the above twelve substances into a 100ml glass three-neck bottle with magnetic stirring function, under the protection of nitrogen, and under the condition of heating temperature of 50°C, stir while heating, the mixture in the bottle is melted from solid to In liquid state, heat for 3 minutes. When the mixture in the bottle reaches 70°C, keep warm for 30 minutes. After heat preservation, cool down to room temperature naturally to form a milky white opaque nematic mixed liquid crystal material, which is sealed and stored.

Embodiment 3

[0049]

[0050]

[0051] Take 50g of mixed liquid crystal material as an example to describe its preparation process: Use an electronic balance to weigh the following twelve substances:

[0052] Monomer liquid crystal

[0053] Put the above twelve substances into a 100ml glass three-neck bottle with magnetic stirring function, under the protection of nitrogen, and under the condition of heating temperature of 50°C, stir while heating, the mixture in the bottle is melted from solid to In liquid state, heat for 3 minutes. When the mixture in the bottle reaches 70°C, keep warm for 30 minutes. After heat preservation, cool down to room temperature naturally to form a milky white opaque nematic mixed liquid crystal material, which is sealed and stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com