Forced oil circulation water-cooling radiator

A water-cooled radiator and forced oil circulation technology, which is applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of obvious temperature difference of oil layer in static state, corrosion and perforation of copper or aluminum tubes, scale reduction and replacement Heat effect and other problems, to achieve enhanced anti-corrosion effect, easy and convenient cleaning, and simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

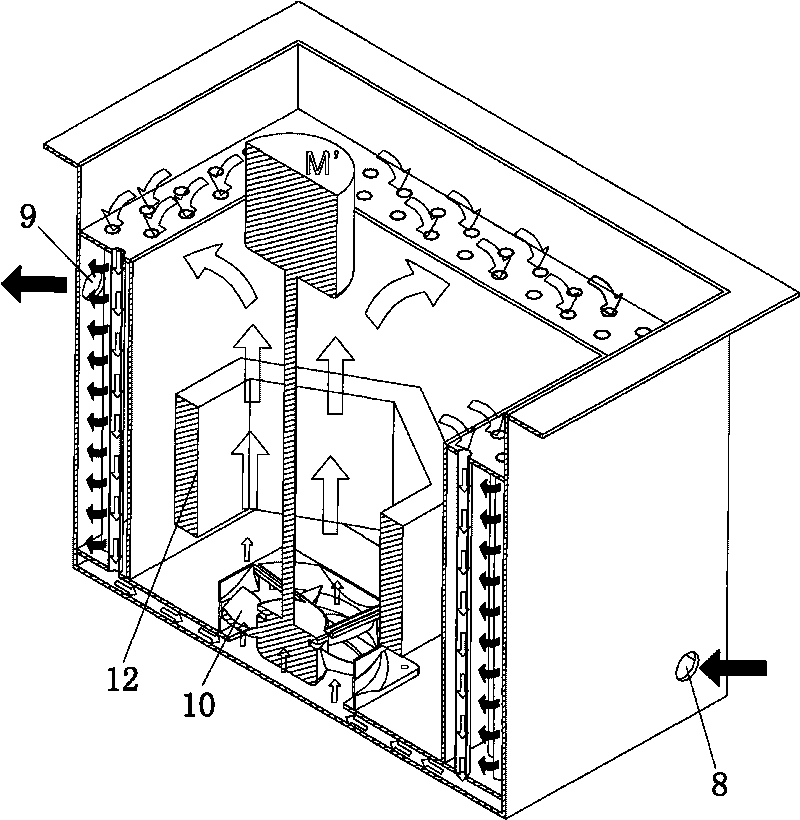

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

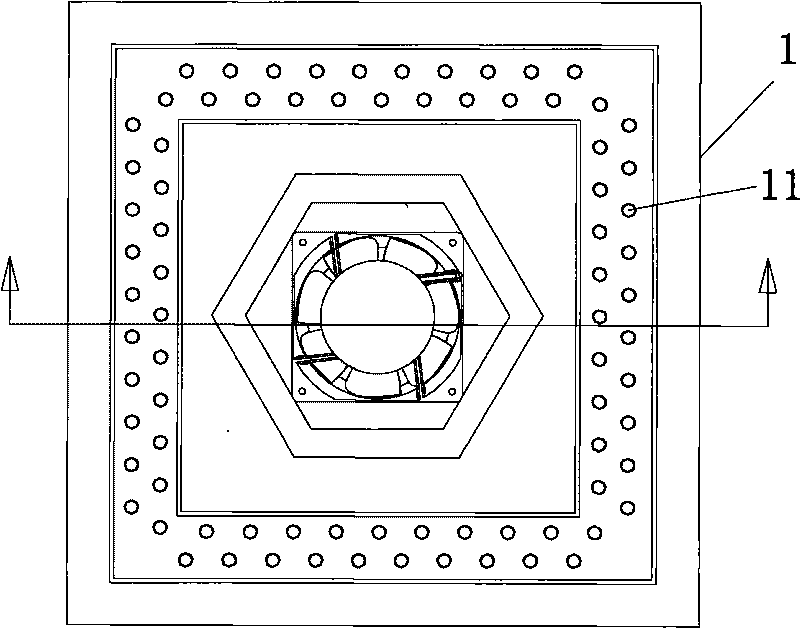

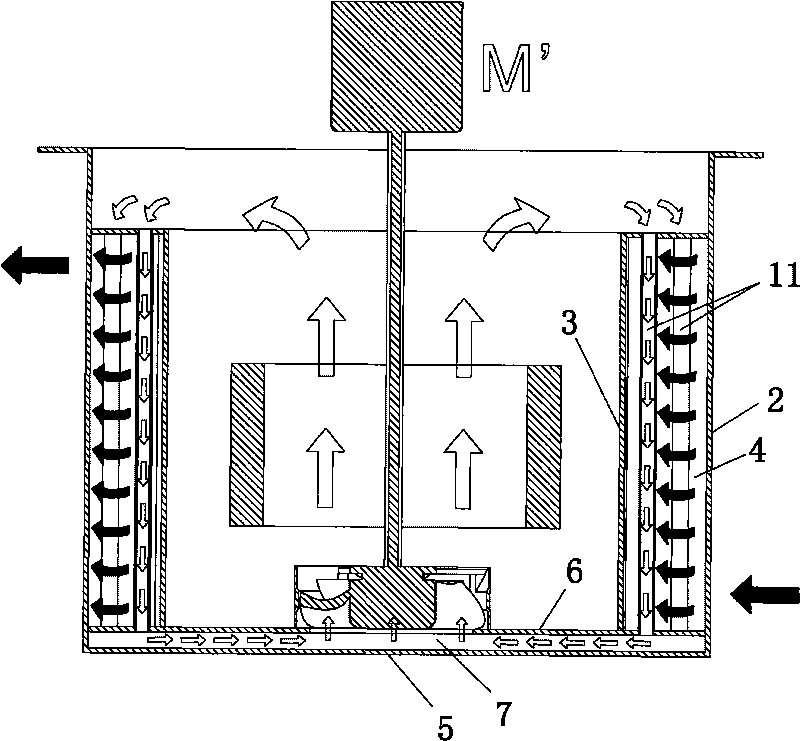

[0028] Such as figure 1 with figure 2 A forced oil circulation water-cooled radiator shown includes a box body 1 and a cover sealed on the box body 1 (the cover body is not shown in the figure), and a side wall is formed between the outer wall 2 and the inner wall 3 on the side of the box body 1. A cavity 4, a bottom cavity 7 is formed between the outer wall 5 and the inner wall 6 of the bottom surface of the box body 1, and the side cavity 4 and the bottom cavity 7 are not connected to each other;

[0029] The side cavity 4 is filled with water, and the outer wall 2 on the side of the box body 1 is provided with a water inlet 8 and a water outlet 9;

[0030] The tank 1 is filled with oil, the bottom cavity 7 is provided with an agitator 10, and the side cavity 4 is provided with an oil pipe 11. One end of the oil pipe 11 is connected to the inside of the tank 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com