Autonomous-heat-exchange parallel-connection closed type forklift static-pressure drive system

A drive system and forklift technology, applied in the direction of power unit, vehicle components, cooling combination arrangement of power unit, etc., can solve the problem that the research and practical application of static pressure drive forklifts have not been really carried out, and loaders and excavators cannot be simply copied Static pressure drive system, low-speed performance requirements and other issues, to achieve superior dynamic characteristics, improve energy utilization efficiency, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

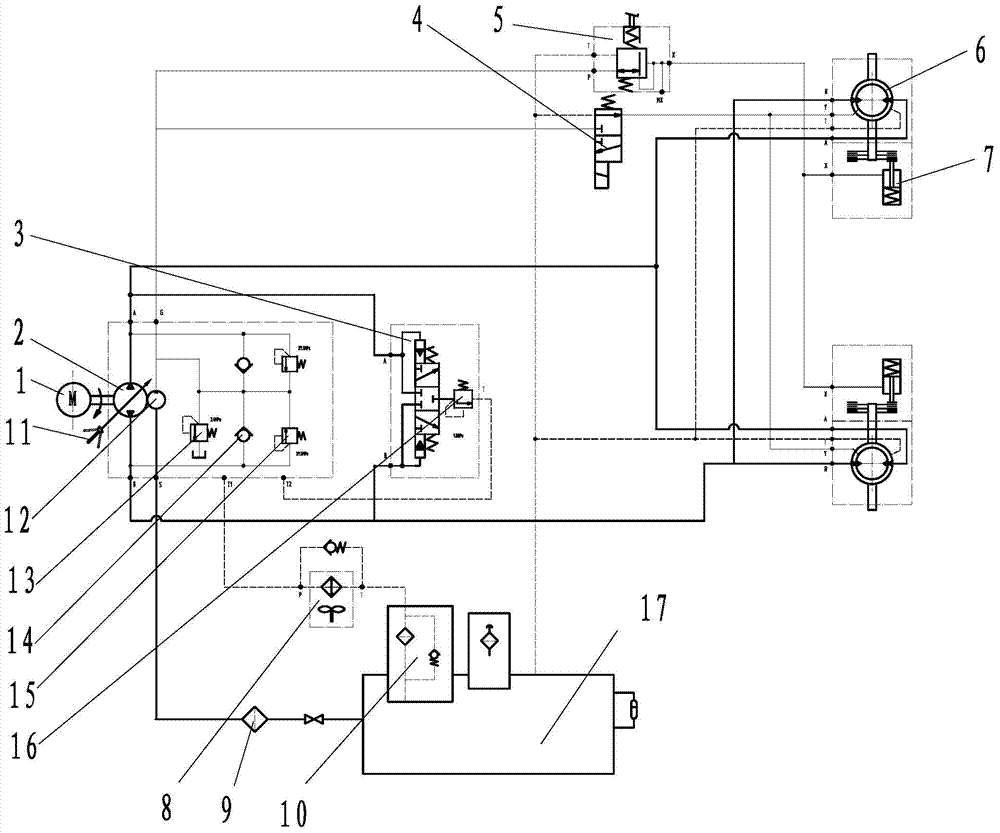

[0023] see figure 1 Shown: an independent heat exchange parallel closed forklift static pressure drive system, which includes engine 1, variable displacement plunger pump 2, heat exchange valve 3, variable speed valve 4, parking control valve 5, hydraulic motor 6, parking hydraulic pressure Cylinder 7, oil inlet filter 9, oil return cooling device 8, oil return filter 10;

[0024] The power of the hydrostatic drive system is provided by the engine, and the engine 1 is connected with the variable displacement plunger pump 2 by a transmission shaft. The variable displacement plunger pump 2 is a double-outlet swash plate type. By adjusting the input speed of the pump and the position and angle of the swash plate, Adjust the output flow of the variable plunger pump 2 to realize the opening and closing of the variable plunger pump 2;

[0025] The two pressure oil ports of the variable displacement plunger pump 2 are respectively connected in parallel with the hydraulic motor (in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com