Anti-icing and deicing device and method for wings and emages of turbo-prop aircraft

A turboprop and anti-icing technology, applied in de-icing devices, aircraft parts, transportation and packaging, etc., can solve the problems of increasing aircraft accidents, prolonging the time of de-icing, and consuming large amounts of heat, so as to improve system reliability and improve Deicing efficiency and the effect of extending the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

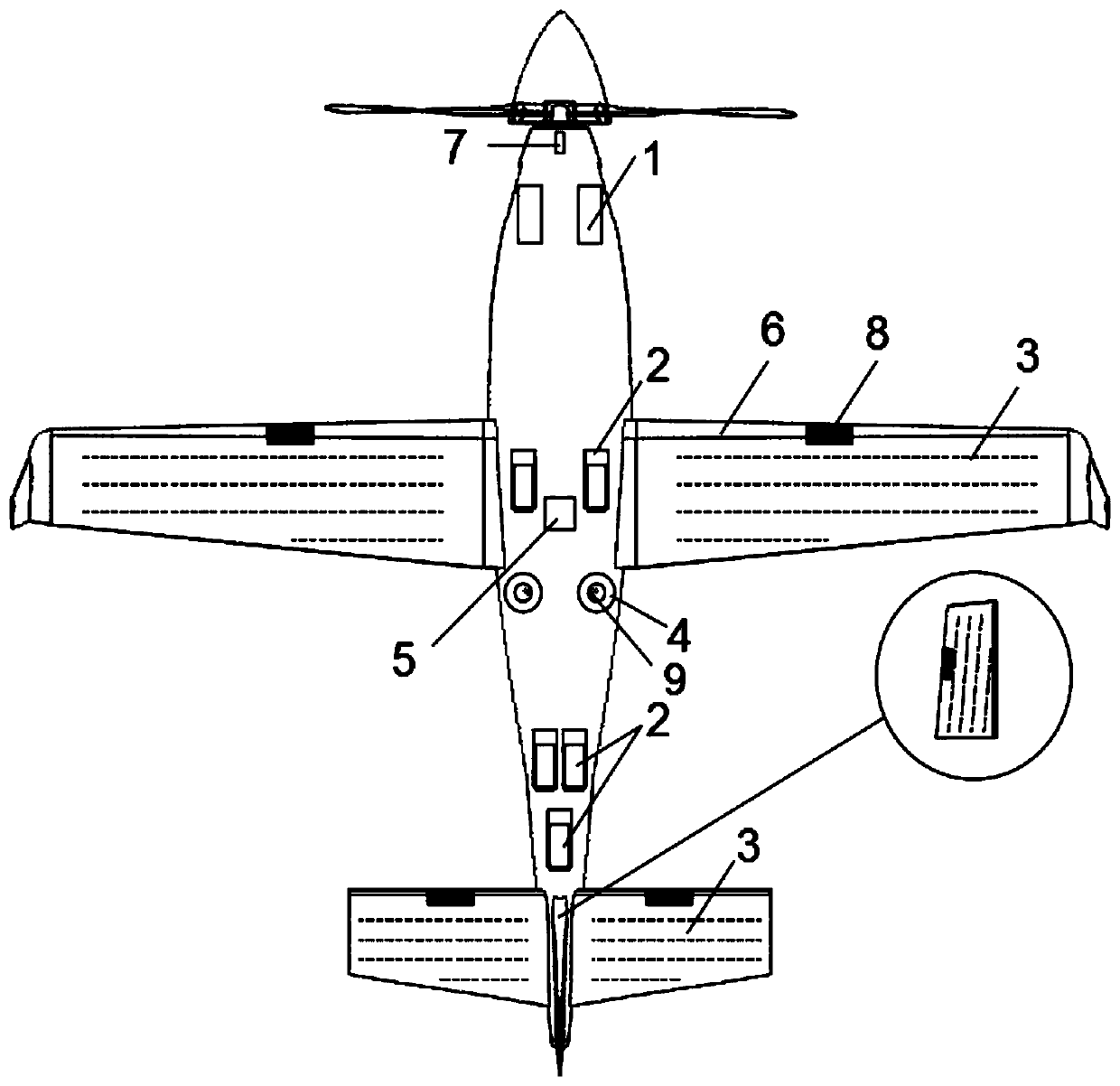

[0072] The installation positions of the main components of this embodiment on the aircraft are as follows: figure 1 Shown.

[0073] Aiming at the shortcomings of single-engine turboprop aircraft anti-icing and deicing technology and the shortcomings of loop heat pipes and TKS used in aircraft anti-icing and deicing, a circuit using engine waste heat is proposed based on the improvement of loop heat pipes. The heat pipe assists the efficient, economical and reliable anti-icing and deicing device and method of the TKS system. It mainly performs anti-icing and deicing on the wings and tail of single-engine turboprop aircraft.

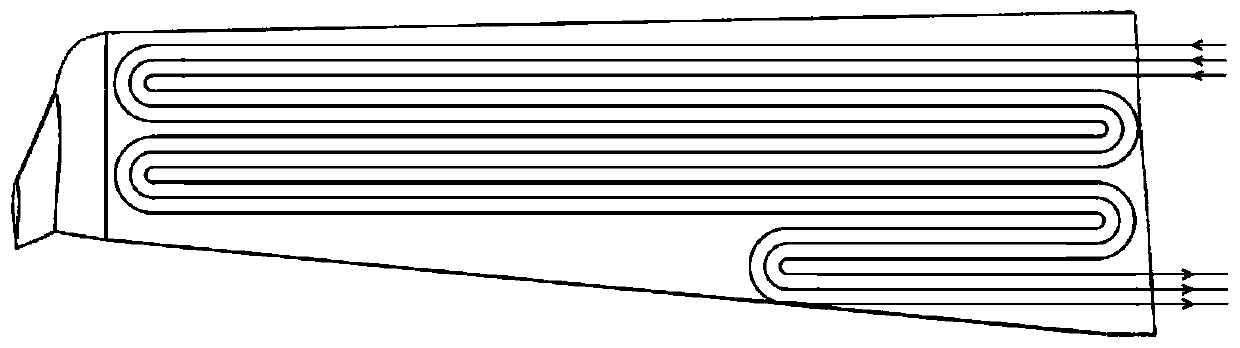

[0074] An anti-icing and deicing device for the wing and tail of a turboprop aircraft, comprising:

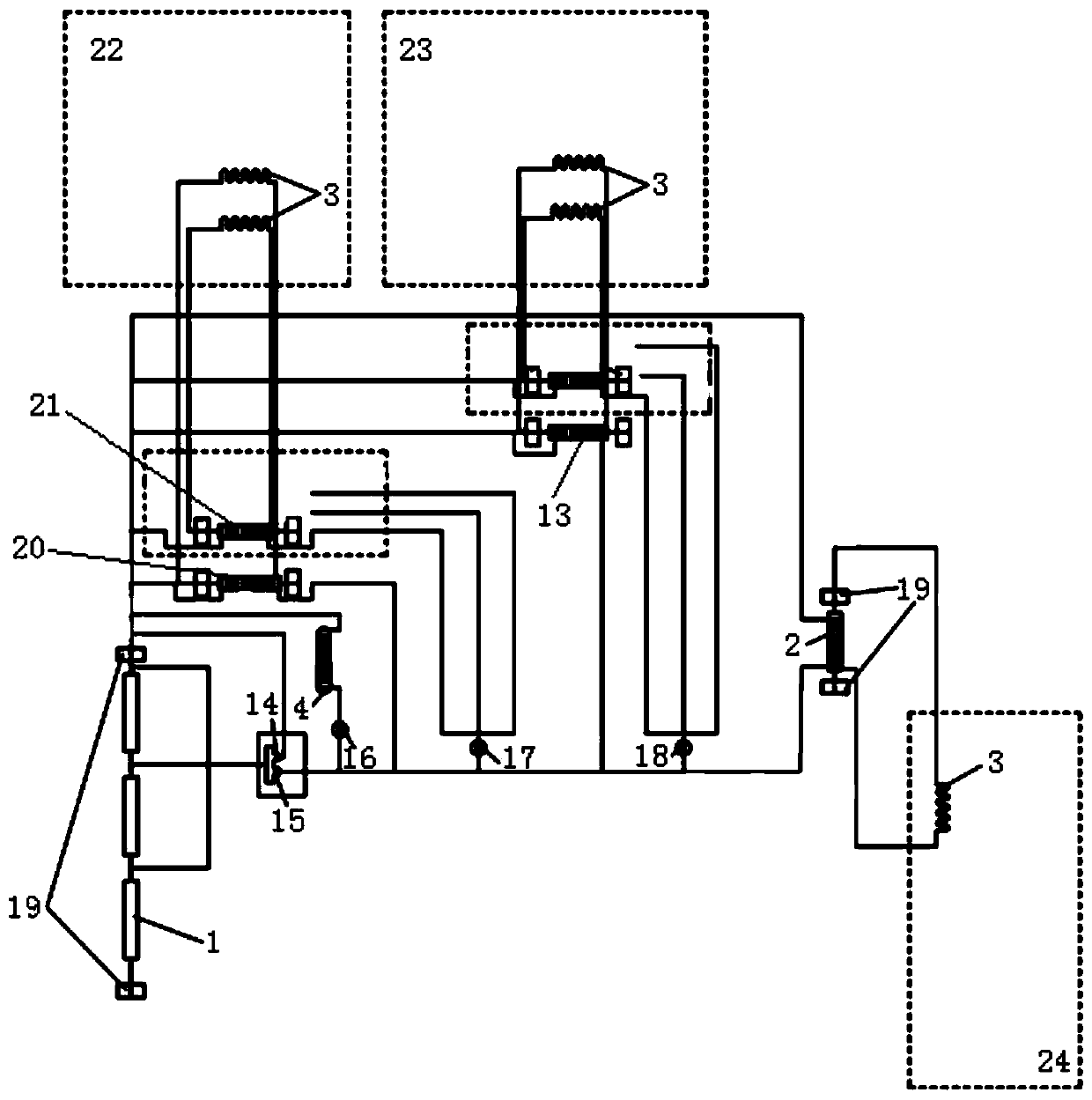

[0075] System closed loop: including heat transfer evaporator 1 and No. 1 valve 14 that are connected end to end along the flow direction of the working fluid;

[0076] TKS liquid storage tank heating circuit: including heat transfer evaporator 1, steam line, TKS...

Embodiment approach

[0112] Rely on the sensor signal to control the opening and closing of the valve.

[0113] The atmospheric temperature sensor 7 detects the atmospheric temperature and controls the first valve 14 and the second valve 15. The TKS liquid storage tank temperature sensor 9 detects the temperature of the TKS liquid and controls the third valve 16. The icing detector 8 detects whether it is icing, and controls the fourth valve 17, the fifth valve 18 and the pressure pump 5.

[0114] The flow of anti-icing and deicing methods is as follows Figure 8 Shown:

[0115] Step 1: At the beginning, the aircraft starts, and the No. 1 valve 14, the No. 2 valve 15, the No. 3 valve 16, the No. 4 valve 17, and the No. 5 valve 18 are closed.

[0116] Step 2: The atmospheric temperature sensor 7 detects whether the atmospheric temperature is higher than 5°C.

[0117] If it is higher than 5°C, the No. 1 valve 14 is opened and the No. 2 valve 15 is closed, and the aircraft is in the closed state of the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com