Narrow vehicle linear sorting machine and sorting method

A sorting machine and linear technology, applied in sorting and other directions, can solve problems such as inconvenient maintenance, low versatility, complex structure, etc., and achieve the effects of enhancing applicability, reducing use cost, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Finally, it should be noted that: the above is only a preferred embodiment of the present invention, and is not intended to limit the present invention. Although the present invention has been described in detail with reference to the foregoing embodiments, for those skilled in the art, it still The technical solutions recorded in the foregoing embodiments may be modified, or some technical features thereof may be equivalently replaced. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present invention shall be included in the content of the invention within the protection scope of the present invention.

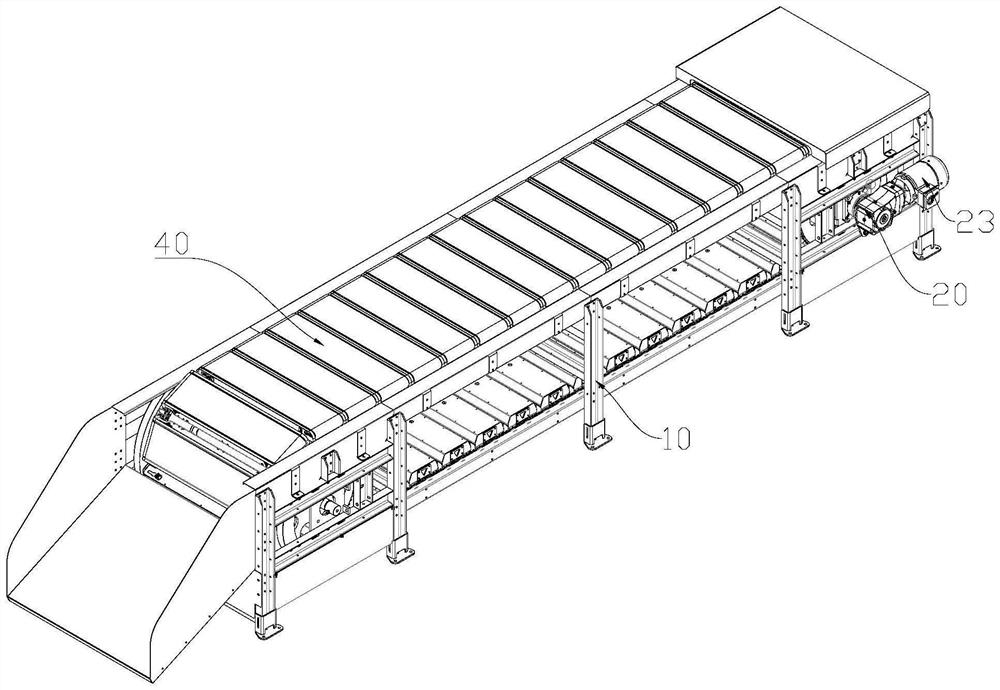

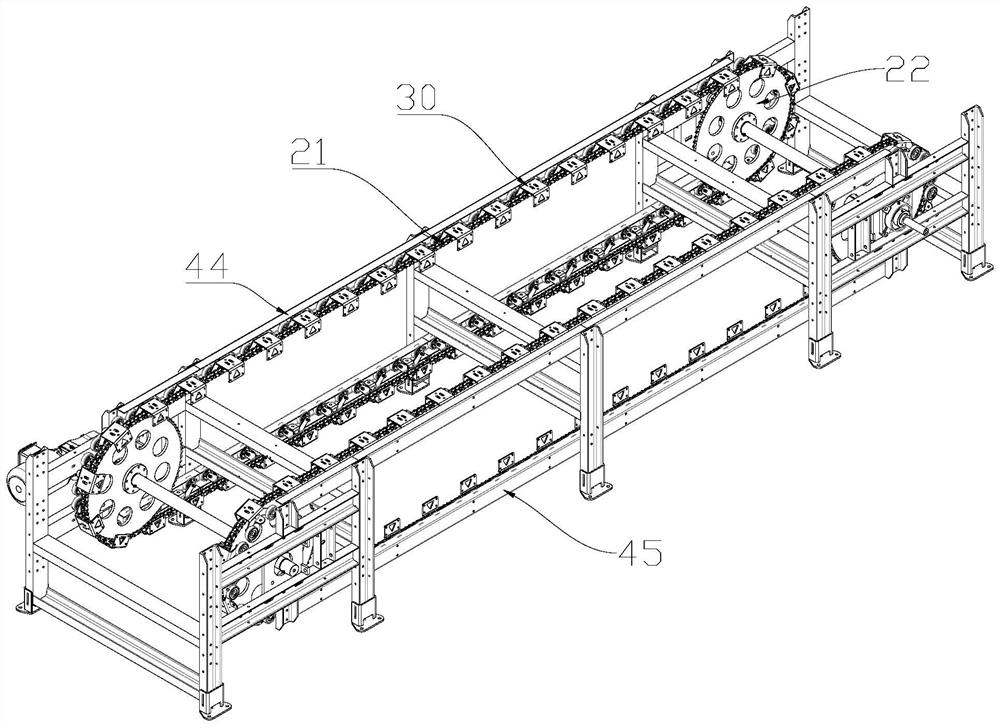

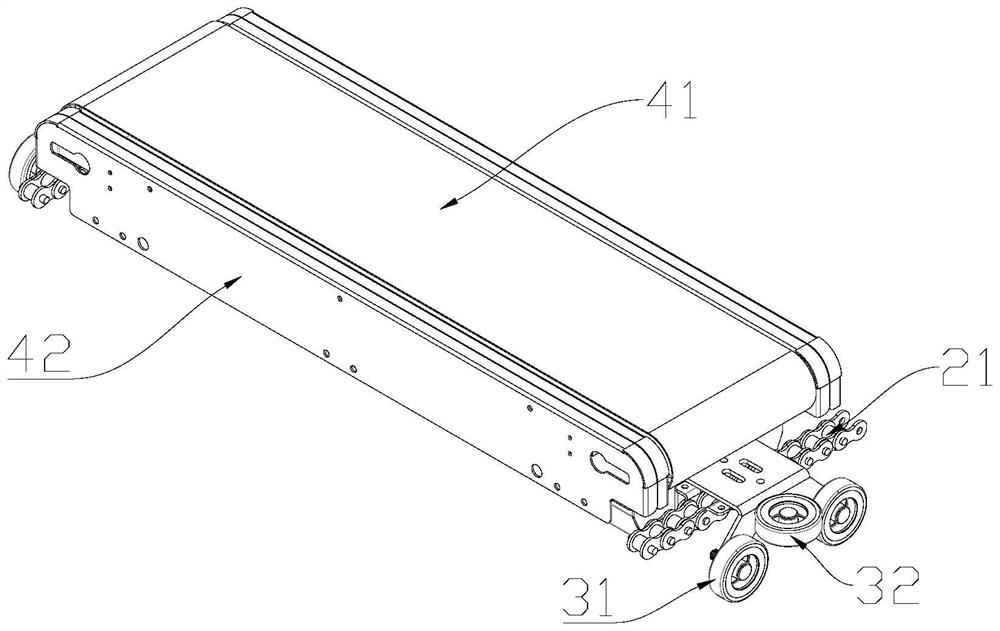

[0031] refer to Figure 1-5 , a narrow car linear sorter, including a frame 10, a driving mechanism 20, a carrying assembly 30, a conveying trolley 40, and a detection coding assembly 50, the carrying assembly 30 is slidably mounted on the frame 10, and the driving mechanism 20 is arranged on the conveying trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com