Damping composite material, damping pressing machine bottom plate structure and refrigerator

A damping composite material and press technology, which is applied in the field of damping and vibration damping materials, can solve the problem of high noise level of the whole refrigerator, and achieve the effects of ensuring long-term work requirements, improving bonding effect and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

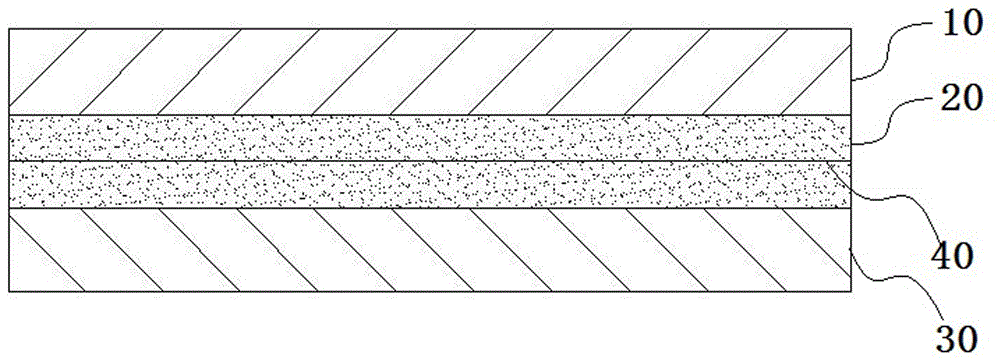

[0037] The preparation method of the bottom plate structure of the vibration damping press comprises the following steps:

[0038] 1) First prepare the damping composite material, weigh the base material and filler according to the formula, and send them into the strong mixer in turn, and fully stir and mix. The mixing time is 8-15min to obtain the mixed raw material, and the temperature of the mixed raw material is raised to 100-140°C , add additives, stir for 5-10 minutes, fully dissolve, and prepare damping slurry;

[0039] 2) Using CNC glue spraying technology, the conveying roller transports the upper metal plate and the lower metal plate to the automatic glue spraying system at a uniform speed at the same time, and the automatic glue spraying equipment evenly coats damping slurry on the inner surface of the metal plate;

[0040] 3) laying a layer of mesh-shaped glass fiber layer film 40 on the lower metal plate coated with damping slurry;

[0041] 4) The upper and lower...

Embodiment 1

[0048] A vibration damping press floor structure, comprising an upper metal plate, an intermediate damping layer and a lower metal plate, the intermediate damping layer is made of the following raw materials in parts by weight: 40 parts of epoxy resin, 20 parts of polyurethane polymer, glass fiber 20 parts, 5 parts of barium sulfate, 10 parts of mica flakes, 3 parts of talc powder, 5 parts of graphite, 5 parts of nano silicon dioxide, 5 parts of zinc oxide whiskers, 2.5 parts of coupling agent, 2.5 parts of curing agent, epoxy resin 5 parts of base material adhesive. The glass fiber has a length of 300-500 μm and a diameter of 10-20 μm. The upper metal plate is a hot-dip galvanized sheet with an elastic modulus ≥ 300GPa, with a thickness of 1.0mm; the lower metal plate is a hot-dip galvanized sheet with an elastic modulus ≤ 200GPa, with a thickness of 1.0mm; the overall thickness of the damping layer is 50 μm.

[0049] Its preparation method: 1) Weigh the base materials and ...

Embodiment 2

[0053] A vibration damping press base plate structure, comprising an upper metal plate, an intermediate damping layer and a lower metal plate, the intermediate damping layer is made of the following raw materials in parts by weight: 50 parts of epoxy resin, 22 parts of polyurethane polymer, glass fiber 25 parts, 8 parts of barium sulfate, 15 parts of mica flakes, 5 parts of talc powder, 6 parts of graphite, 18 parts of nano silicon dioxide, 6 parts of zinc oxide whiskers, 3 parts of coupling agent, 2.5 parts of curing agent, epoxy resin 7 parts of base material adhesive. The glass fiber has a length of 300-500 μm and a diameter of 10-20 μm. The upper metal plate is a hot-dip galvanized sheet with a modulus of elasticity ≥ 250GPa, with a thickness of 1.2 mm; the lower metal plate is a galvanized plate with a modulus of elasticity ≤ 200 GPa, with a thickness of 1.2 mm; the overall thickness of the damping layer is 100 μm.

[0054] Its preparation method: 1) Weigh the base mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com