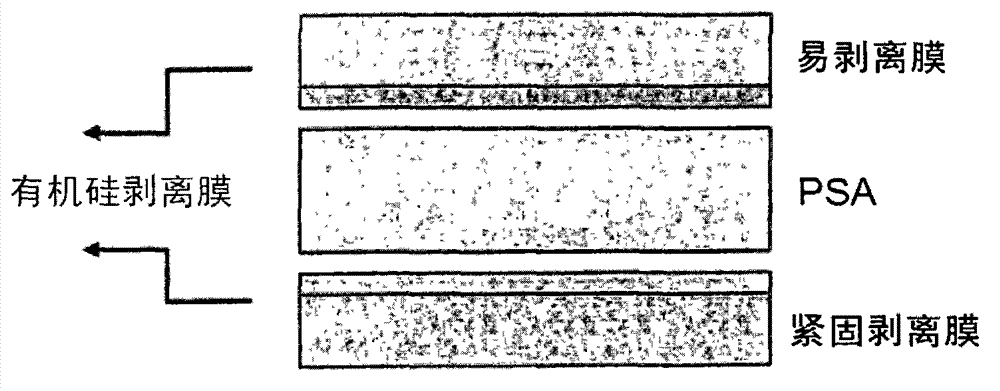

Silicone release film with improved release performance and anti-adhesion performance

A technology of silicone and peeling film, which is applied in the direction of film/flaky adhesives, adhesives, chemical instruments and methods, etc. It can solve the problems of increased haze, separation of inactive particles, difficult film, low peeling force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

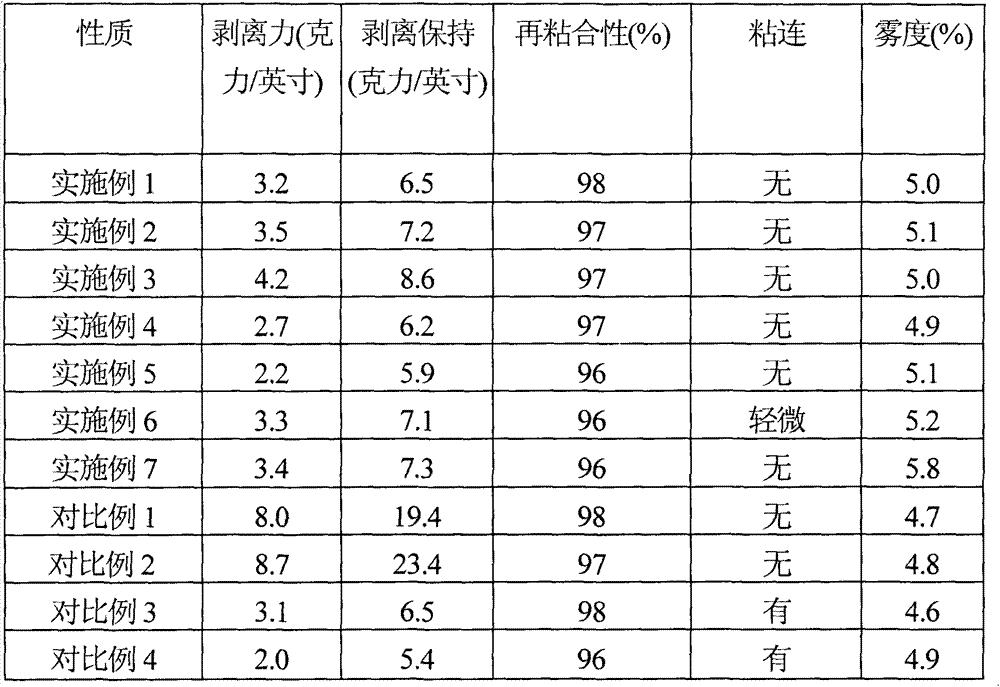

Examples

Embodiment 1

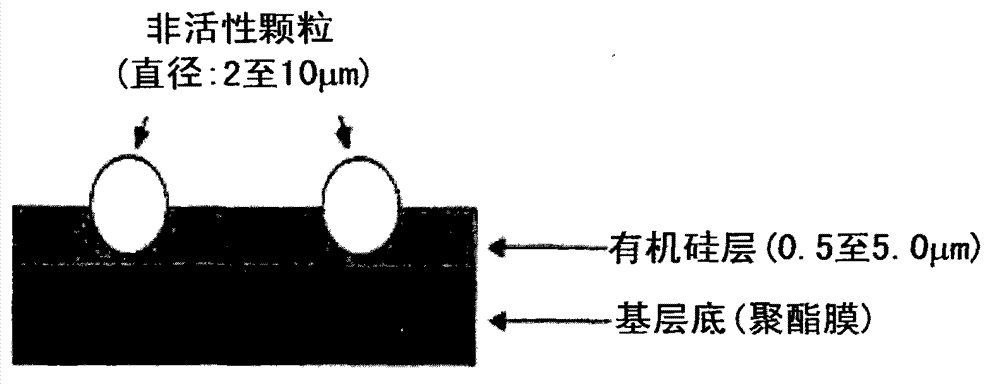

[0057] By mixing 5% by weight of polydimethylsiloxane with hexenyl groups (LTC750A, Dow Corning), 0.2% by weight of hydrogen siloxane, 350 ppm of platinum catalyst, 0.02% by weight of organic inactive particles with an average diameter of 5 μm (cross-linked silicone particles) and the balance of toluene and methyl ethyl ketone (MEK) mixed solvent to prepare a solvent-based mixture.

[0058] The composition was applied to a 50 μm thick PET film using conventional coating methods with a coating thickness of 1 μm measured after its drying. The film was heat-treated at 150° C. for 30 seconds to obtain a silicone release film.

Embodiment 2

[0060] The operation of Example 1 was repeated except that polydimethylsiloxane (SD7226, Dow Corning) having a vinyl group was used.

Embodiment 3

[0062] The operation of Example 1 was repeated, except that the coating thickness was changed to 0.5 μm, and the average diameter of the organic inactive particles was changed to 2 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com