Method for detecting geometric shape of back of tailor-welding weld and implementing device thereof

A technology of geometric shape and detection method, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high welding seam detection cost, closed-loop control, etc., achieve fast measurement speed, ensure effectiveness, and realize closed-loop feedback control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

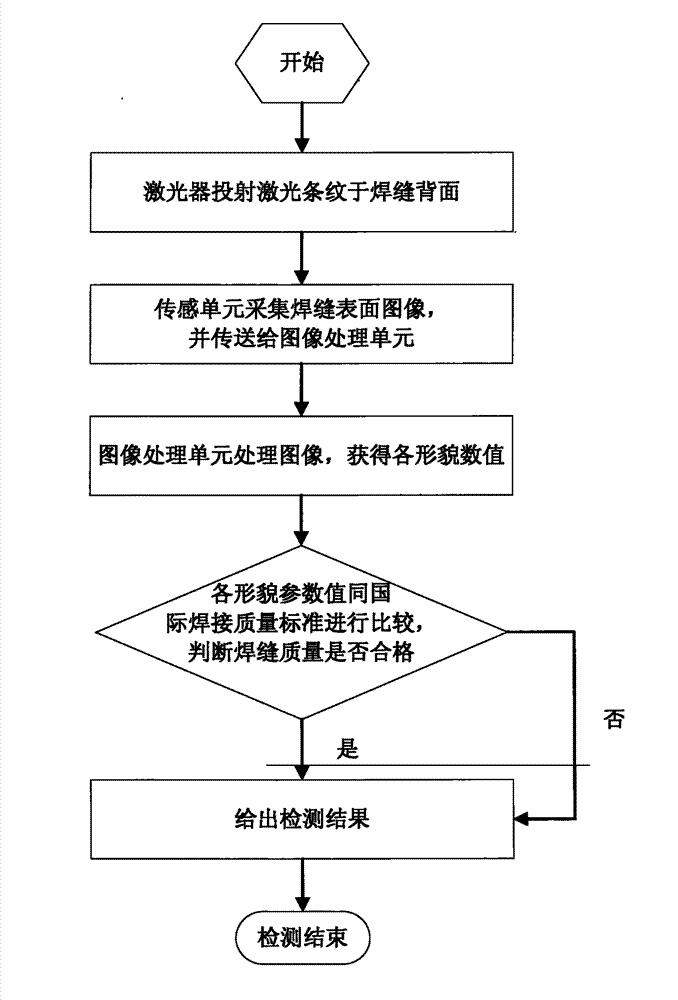

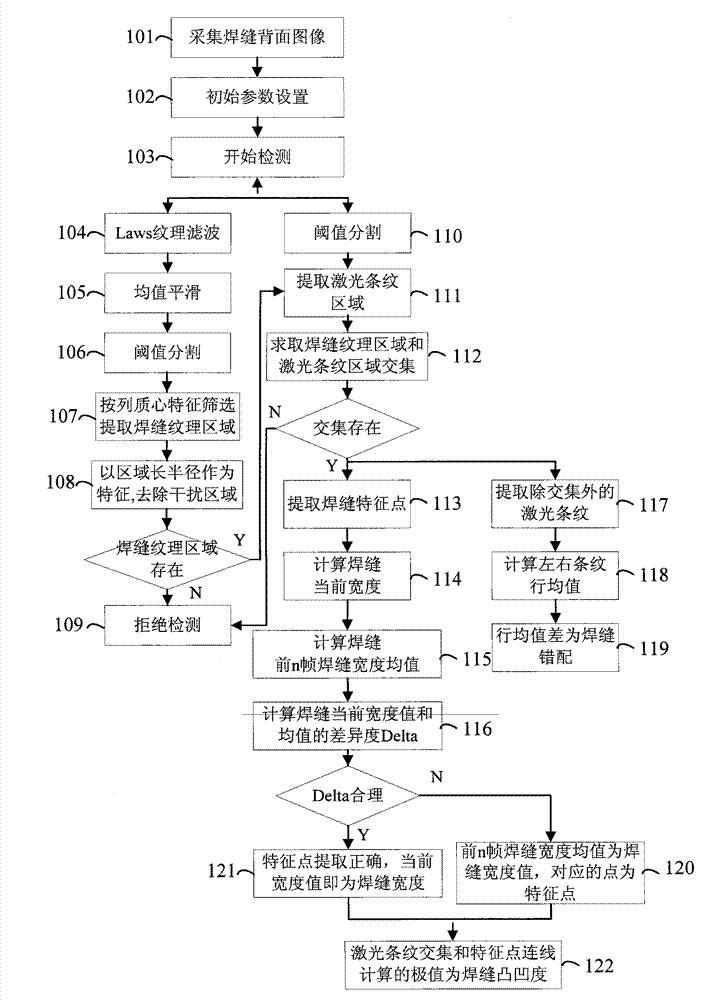

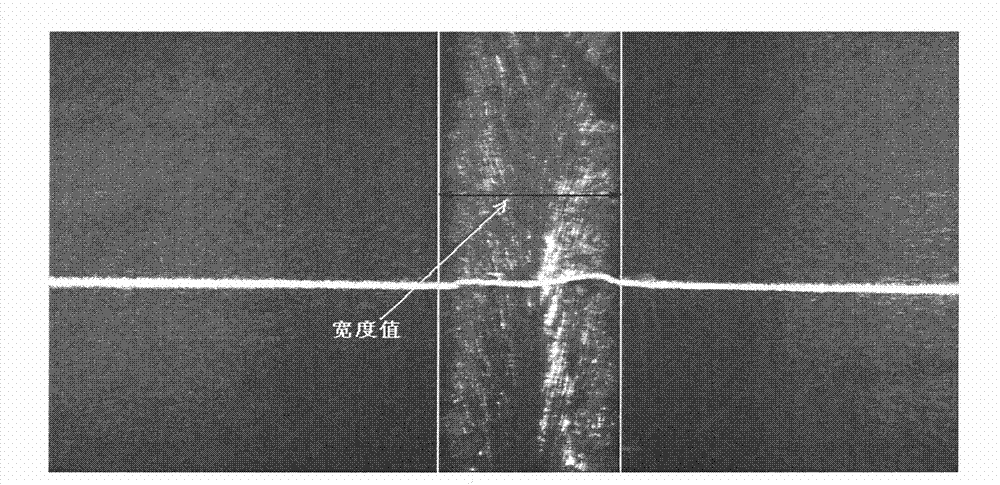

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056] Such as Figure 4 As shown, the device for realizing the geometry detection of the back side of the laser tailor welding seam in the present invention includes: a sensing unit 1, an image processing unit 2, and a parameter setting and control unit 3, wherein the sensing unit 1 is used to generate laser stripes on the detected On the weld seam area, collect the seam image of laser tailor welding and transmit it to the image processing unit 2; the image processing unit 2 processes the collected seam image under the control of the parameter setting and control unit 3; the parameter setting and control unit 3. Set the parameters of the sensing unit 1 and the image processing unit 2, and communicate with the sensing unit 1, the image processing unit 2, and the host computer 5 respectively. The host computer 5 includes a PLC or a robot.

[0057] Sensing uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com