An in-situ purification treatment system and method for directly supplying gas-fired boilers with low-sulfur oilfield associated gas

A technology for oilfield associated gas and gas boiler, which is applied in the field of oilfield associated gas resource utilization, and can solve problems such as difficulty in meeting continuous work requirements, low hydrogen sulfide content, and scattered crude oil well sites and sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

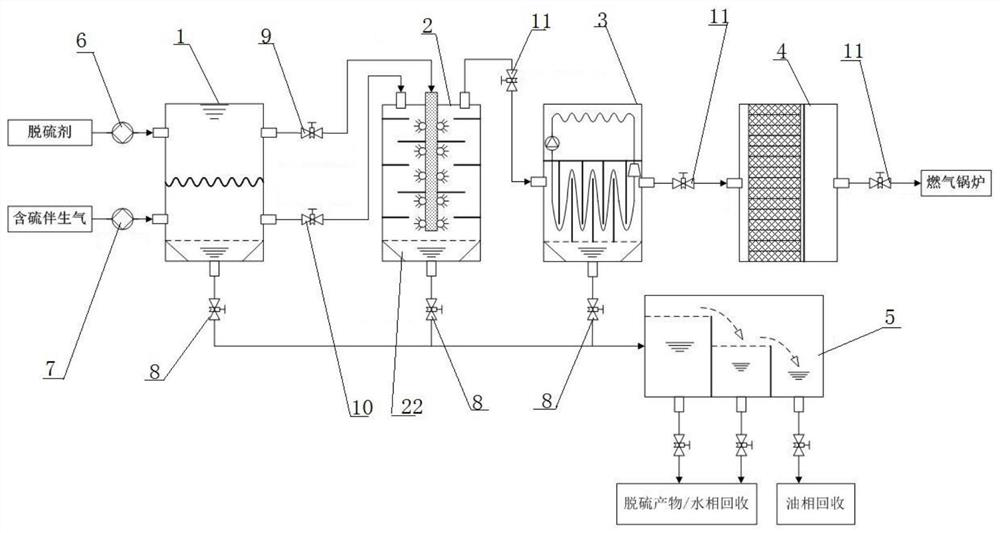

[0040] according to Figure 1-Figure 6 The in-situ purification treatment system of a low-sulfur oilfield associated gas direct-supply gas-fired boiler is shown, including an energy storage and voltage stabilization device 1, an atomization and trapping device 2, a condensation and liquid removal device 3, a drying and filtering device 4 and a liquid phase Recovery device 5; the energy storage and voltage stabilization device 1, atomization and trapping device 2, condensation liquid removal device 3 and dry filter device 4 are connected sequentially from front to back, and the liquid phase recovery device 5 is connected with the energy storage and voltage stabilization device respectively 1. The atomization and trapping device 2 is connected to the condensation and liquid removal device 3 .

[0041] In actual use, the sulfur-containing associated gas supply source and the desulfurizer liquid supply source enter the gas storage chamber 13 and liquid storage chamber of the energ...

Embodiment 2

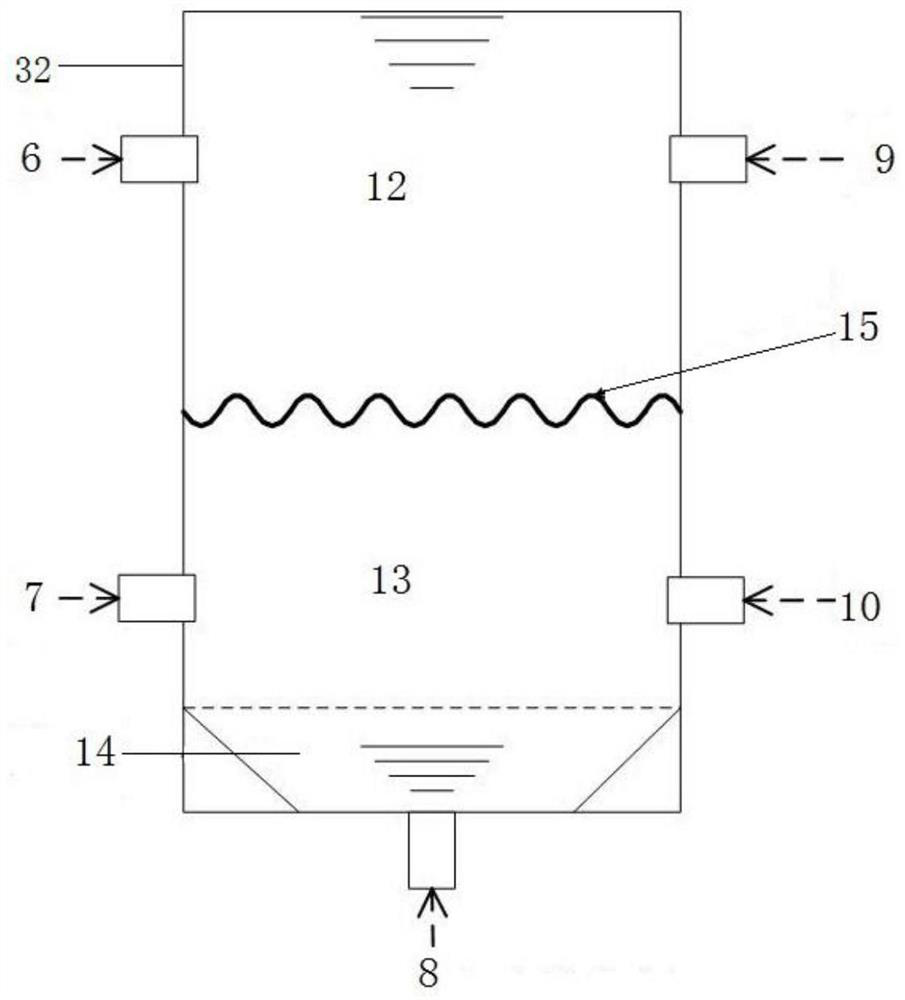

[0044] according to figure 1 and figure 2 The shown in-situ purification treatment system for low-sulfur oilfield associated gas direct-supply gas-fired boiler differs from Embodiment 1 in that the energy storage and voltage stabilization device 1 includes an energy storage and voltage stabilization device housing 32, The elastic isolation balance layer 15 and the first liquid discharge funnel 14, the elastic isolation balance layer 15 is horizontally arranged in the housing 32 of the energy storage and voltage stabilization device, and divides the housing 32 of the energy storage and voltage stabilization device into two upper and lower chambers, The upper part is a liquid storage chamber 12, and the lower part is an air storage chamber 13. The housing 32 of the energy storage and voltage stabilizing device is provided with a liquid inlet, an air inlet, a liquid outlet, an air outlet and a liquid outlet. The liquid inlet and The liquid outlet is arranged on the side wall of...

Embodiment 3

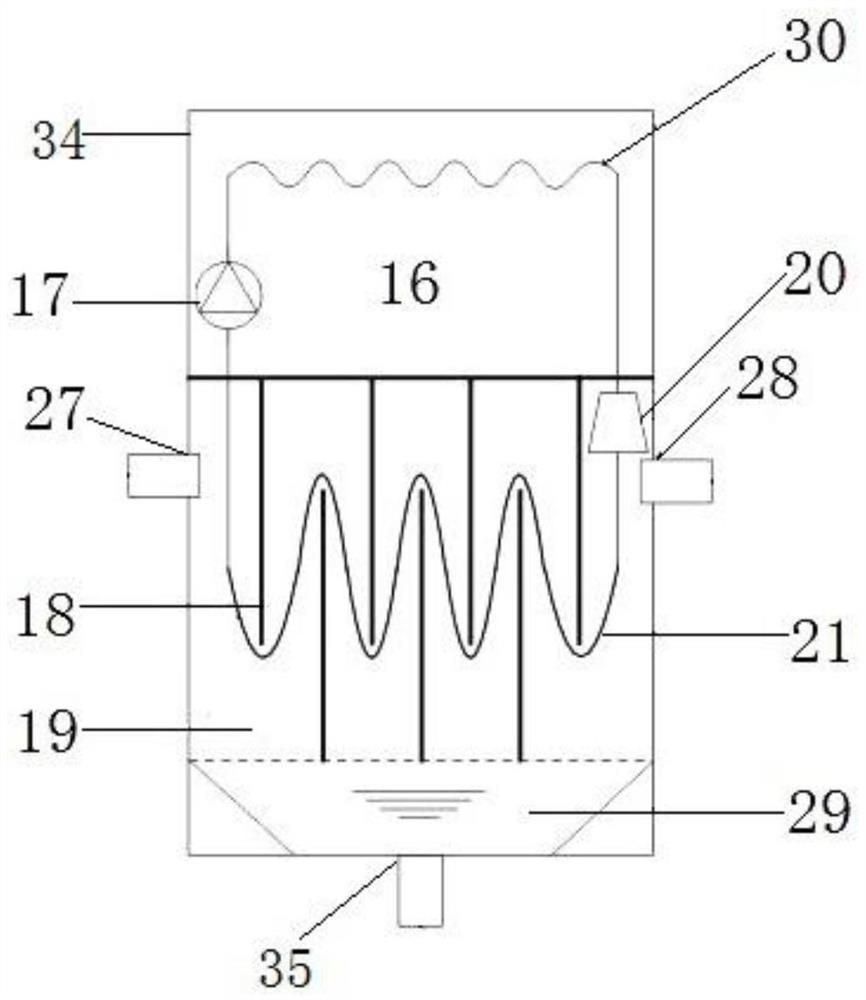

[0051] according to figure 1 and Image 6 The shown in-situ purification treatment system for low-sulfur oilfield associated gas direct-supply gas-fired boiler differs from the first embodiment in that the atomization trapping device 2 includes an atomization trapping device housing 31, The second liquid discharge funnel 22 and the atomization mechanism 33; the upper bottom surface of the atomization and trapping device housing 31 has an air inlet and an air outlet, and the lower and upper bottom surface of the atomization and trapping device housing 31 has a drain The air inlet is connected to the housing 31 of the atomization and trapping device, the gas outlet is connected to the condensation liquid removal device 3, and the liquid discharge port is connected to the liquid phase recovery device 5; the atomization mechanism 33 is connected to the mist In the atomization trapping device housing 31, the upper end of the atomization mechanism 33 extends to the outside of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com