A miniaturized underwater hydraulic manipulator arm joint structure

A technology of joint structure and robotic arm, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of fewer operating manipulators, the structure of the manipulator arm is only applicable, and cannot meet the requirements of underwater operations, etc., to achieve small volume and weight, large rotation The effect of strong angle and driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

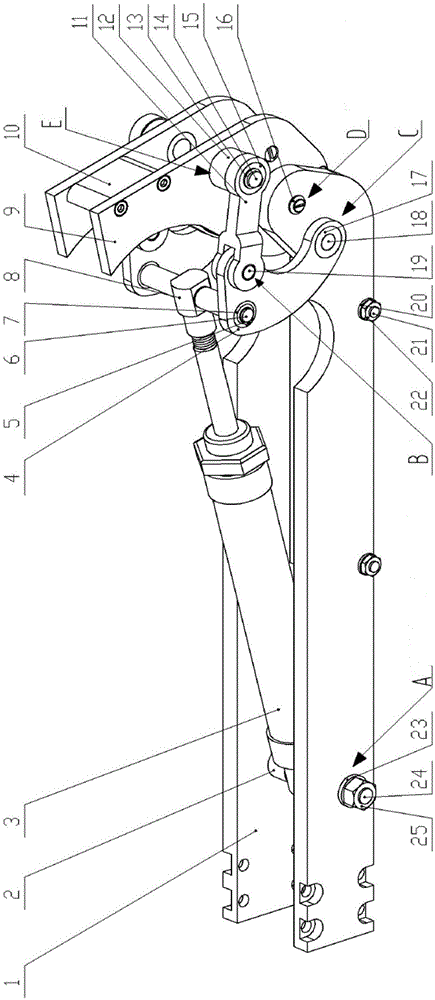

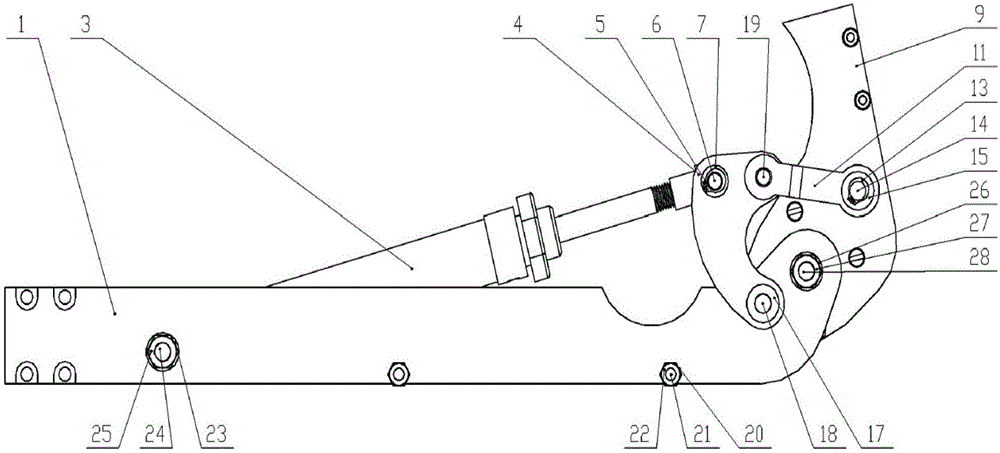

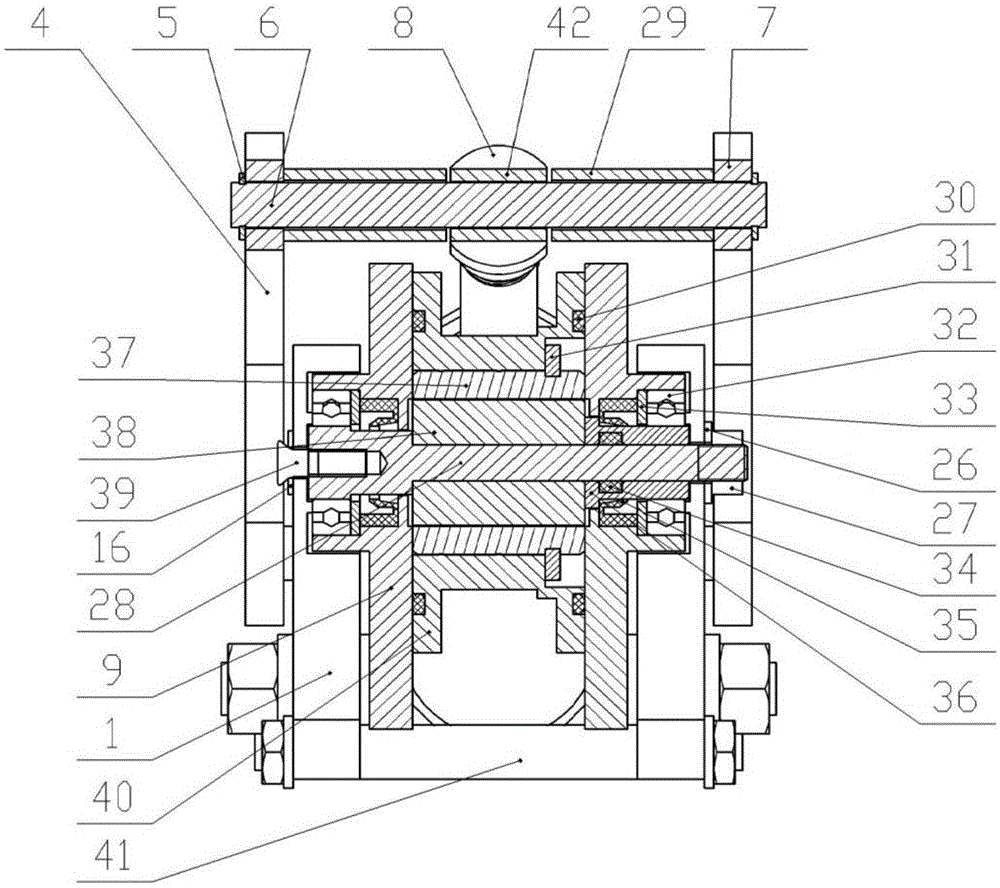

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] An important part of the underwater hydraulic manipulator of the present invention provides the manipulator with the driving force for underwater operations, and feeds back operating parameters such as the angle and angular acceleration of the manipulator's joints through its own position detection device to facilitate the control of the manipulator joints by the host computer; The patent of the invention adopts oil-hydraulic drive six-point mechanism, so that the joint can rotate up to 180°, which can provide a relatively large and stable driving torque for the manipulator, and has a compact structure, small volume and weight, and meets the design requirements for the miniaturization of the manipulator. .

[0027] The present invention adopts the oil-hydraulic drive mode, and the manipulator joint is mainly composed of four parts: the manipulator arm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com