Method for intelligently controlling melting temperature field of glass melting furnace

A glass melting furnace and melting temperature technology, used in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve problems such as melting temperature fluctuations, reduce fuel fluctuations, be easy to upgrade, and avoid large fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for intelligently controlling the melting temperature field of a glass melting furnace, comprising the following steps:

[0051]Step S1, by controlling the total amount of fuel, adjust the fuel amount of each small furnace at the same time; adjust the fuel ratio distribution of each small furnace until the melting temperature field of the glass melting furnace is stable; at this time, the hot spot temperature is the standard temperature, and the position of the bubble boundary is the standard temperature Location;

[0052] Step S2, obtaining the hot spot temperature change of the glass melting furnace, and adjusting the total amount of fuel according to the hot spot temperature change;

[0053] When the hot spot temperature decreases, the total amount of fuel is increased;

[0054] When the hot spot temperature increases, reduce the total amount of fuel;

[0055] Usually, the temperature change of the large dome temperature point corresponding to the small fu...

Embodiment 2

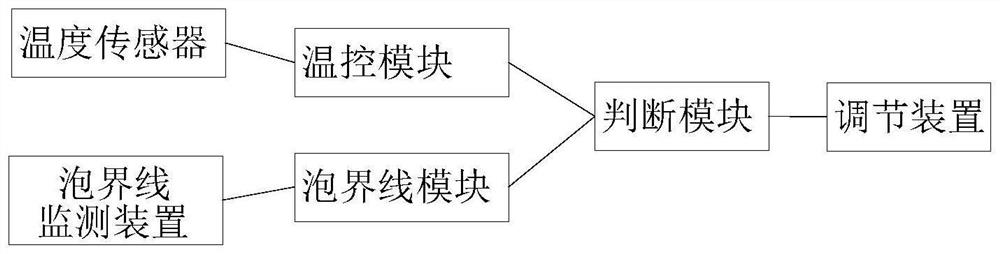

[0070] A system for intelligent control of melting temperature field of glass melting furnace, such as figure 2 As shown, the system includes a temperature sensor, a bubble boundary monitoring device, a control device and a regulating device;

[0071] The temperature sensor is electrically connected to the control device, and sends a temperature signal to it; the bubble boundary monitoring device is electrically connected to the control device, and sends a bubble boundary position signal to it;

[0072] The control device includes a temperature control module, a bubble boundary module and a judgment module;

[0073] The temperature control module receives the temperature signal of the sensor, and sends a first decrease signal to the judgment module when it is determined that the temperature rises; and sends a first increase signal to the judgment module when it is judged that the temperature drops;

[0074] The bubble boundary line module receives the bubble boundary line po...

Embodiment 3

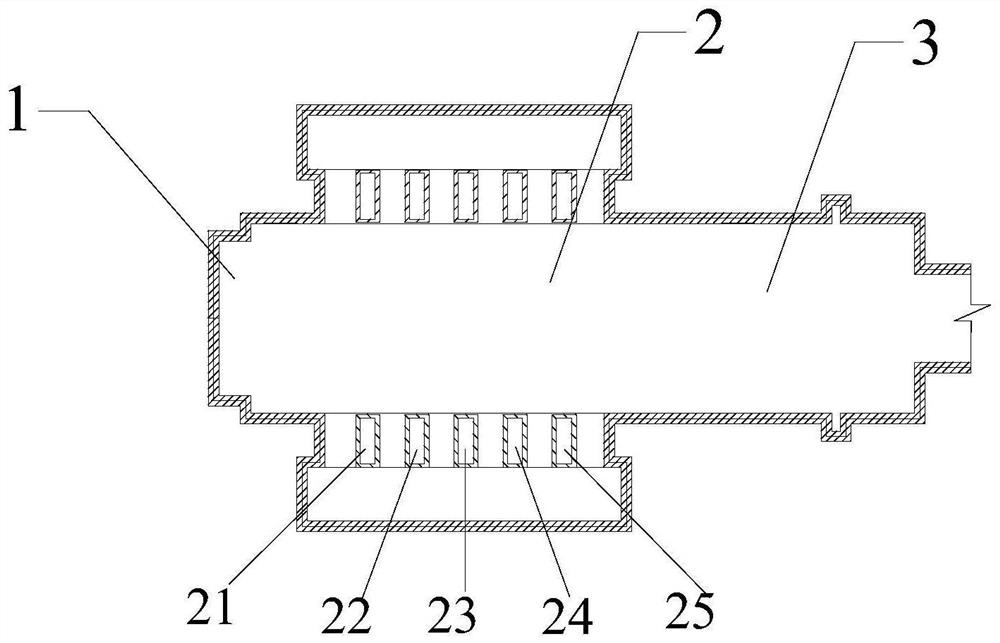

[0084] A glass melting furnace includes the melting temperature field intelligent control system as described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com