A laser tailor welding curved surface seam measurement method and its realization device

A measurement method and laser tailor welding technology, which are applied in measurement devices, optical devices, instruments, etc., can solve the problems such as the need to further improve the measurement accuracy, the inability to perform closed-loop production control, and the inability to obtain the surface normal vector in real time, and achieve the measurement speed. The effect of fast, strong anti-interference ability and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

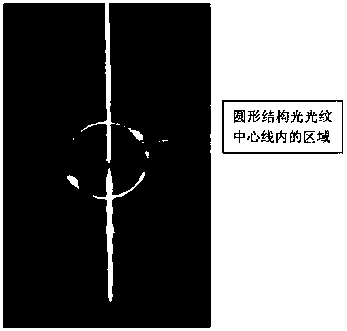

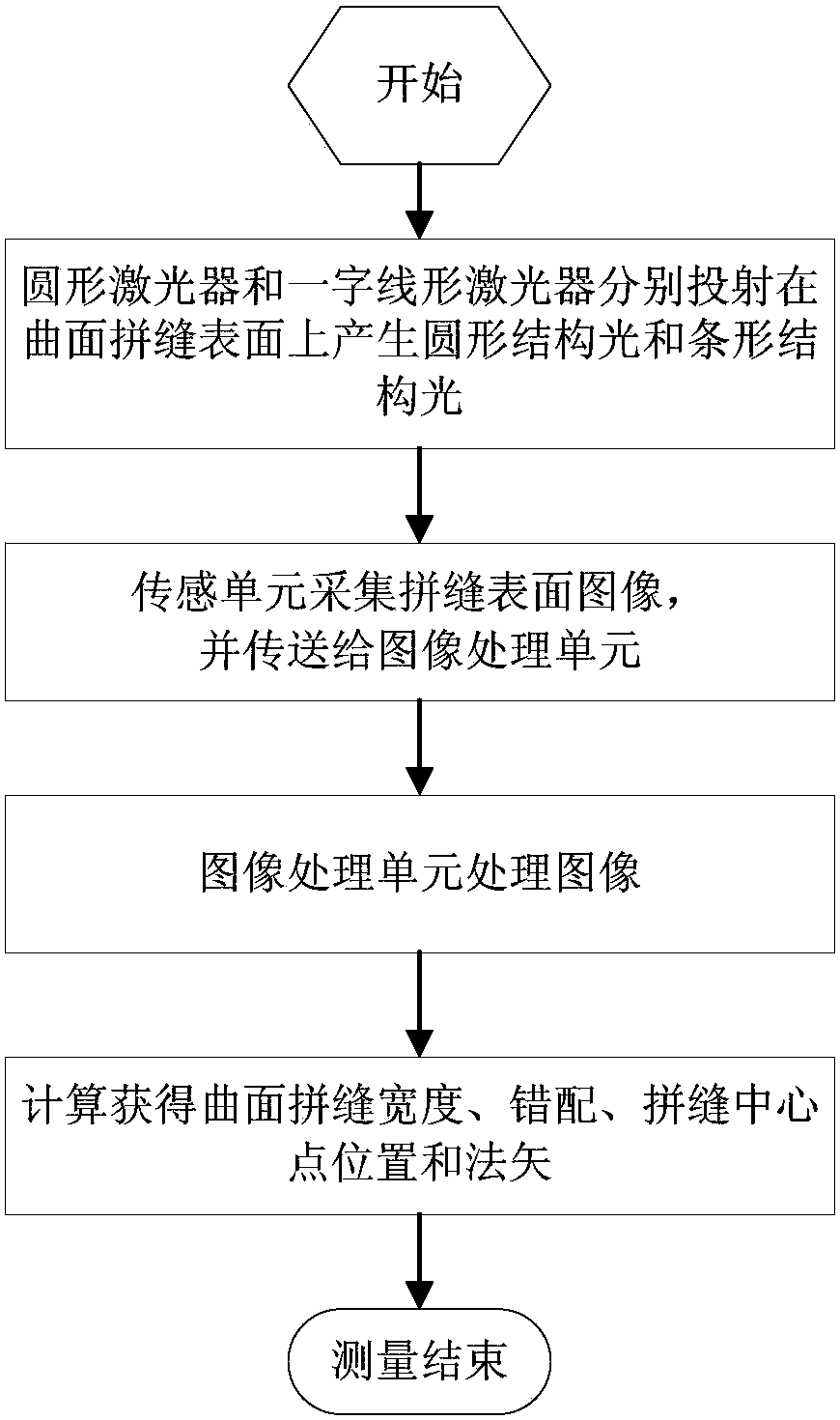

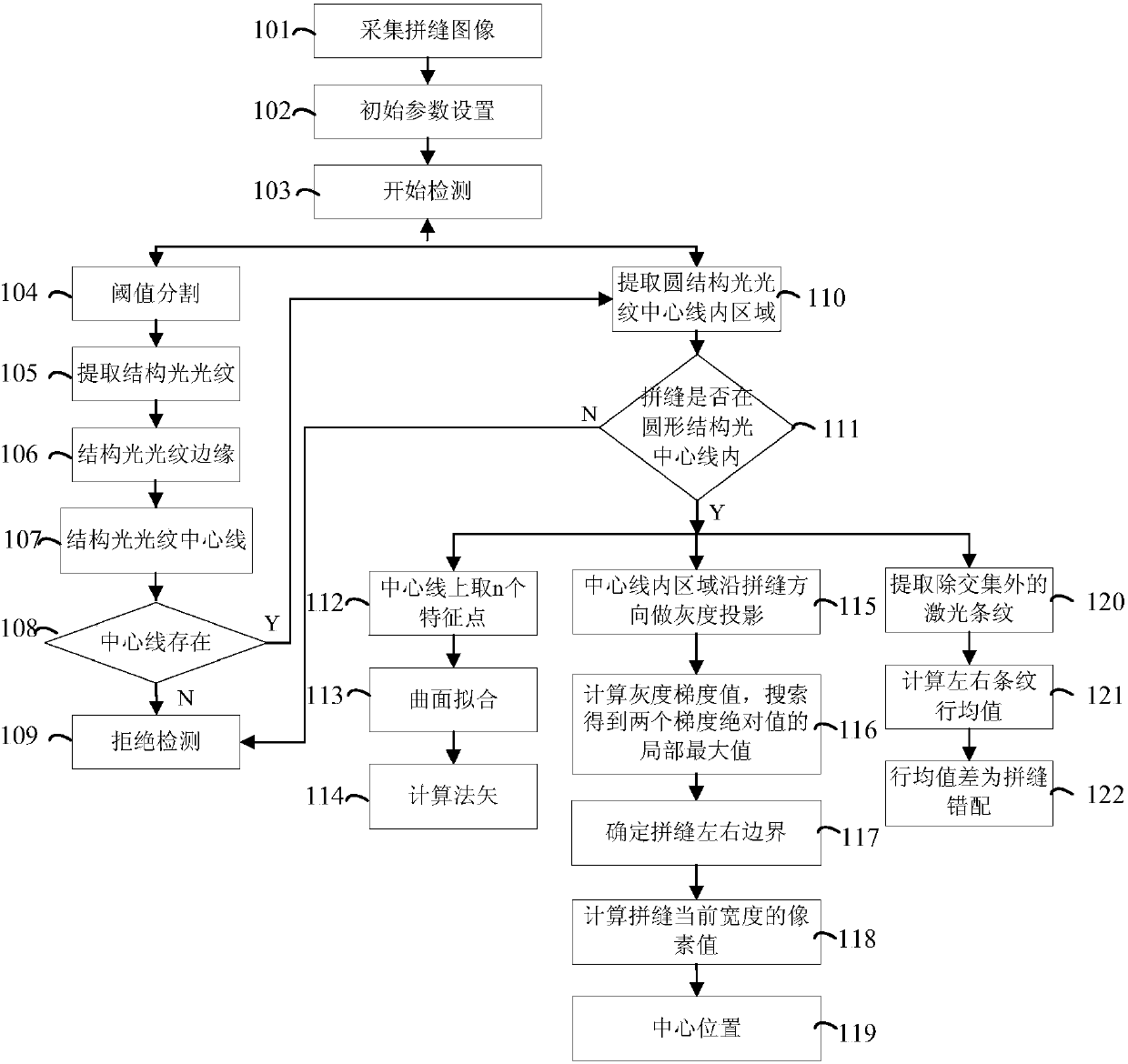

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0068] Such as image 3 As shown, the device for realizing the seam measurement of laser tailor welding curved surface in the present invention includes: a sensing unit 1, an image processing unit 2, and a parameter setting and control unit 3, wherein the sensing unit 1 is used to generate structured light patterns on the detected weld On the seam area, the seam image of laser tailor welding is collected and transmitted to the image processing unit 2; the image processing unit 2 processes the collected weld seam image under the control of the parameter setting and control unit 3; the parameter setting and control unit 3 , set the parameters of the sensing unit 1 and the image processing unit 2, and communicate with the sensing unit 1, the image processing unit 2, and the host computer 5 respectively, and the host computer 5 includes a PLC or a robot.

[0069...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com