Sandwich type SMC sheet and automatic production line thereof

An automatic production line, sandwich-type technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of low degree of automation, low production efficiency, poor fiber transmission effect, etc., to improve mechanical Strength and load-bearing performance, improving production efficiency and product quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

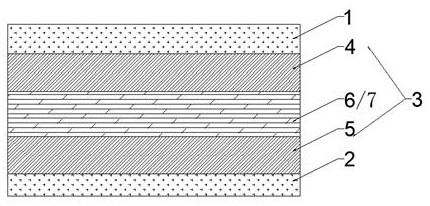

Embodiment 1

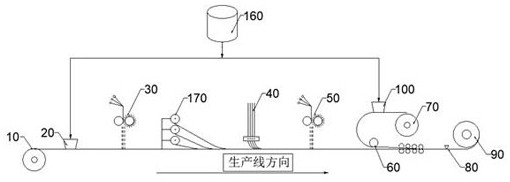

[0029] An automatic production line for sandwich-type SMC sheets, comprising a lower carrying film roller 10, a lower glue groove 20, a first yarn cutter 30, an automatic silk laying device 40, and a second yarn cutter arranged in sequence along the direction of the production line 50. Pressure roller 60, upper bearing film roller 70, sheet weight detection device 80, winding roller 90 and upper glue outlet groove 100, wherein, the upper bearing film roller 70 is located between the pressure roller 60 and the winding roller 90 The upper part is used to convey the upper carrier film 1 to cover the core 3 . In addition, the production line also includes a first program controller 110 , a second program controller 120 and an automatic ingredient feeding device 160 .

[0030] Specifically, the lower carrier film roll 10 winds and transports the lower carrier film 2, and the lower glue outlet tank 20 contains resin paste (epoxy resin paste), and sends the lower carrier film 2 below...

Embodiment 2

[0046] The difference from Embodiment 1 is that, on the production line, an automatic unwinding device 170 is arranged between the first yarn cutter 30 and the second yarn cutter 50 .

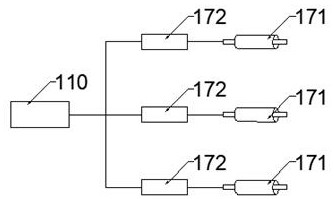

[0047] Specifically, the automatic unwinding device 170 includes 3 fabric reels 171, and the 3 fabric reels 171 are respectively connected with a first motor 172, and the continuous long fiber fabric layer is wound on the fabric reels 171, 3 The first motors 172 are respectively connected to the first program controller 110 by signals. The first program controller 110 sends an instruction to at least one first motor 172, so that the corresponding first motor 172 that receives the instruction is unwound, and controls the unwinding speed, so as to achieve the first short fiber layer 4 and the second short fiber layer. 5. Automatically lay 1-3 layers of continuous long-fiber fabric layers to prepare SMC sheets with a sandwich structure.

[0048] The sandwich-type SMC sheet prepared by the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com