Small underwater hydraulic mechanical arm two-stage drive joint

A technology of manipulators and small water, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of small driving torque, less operating manipulators, and rare miniaturized hydraulic manipulators, and achieve a small ratio of volume to weight to driving force and a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

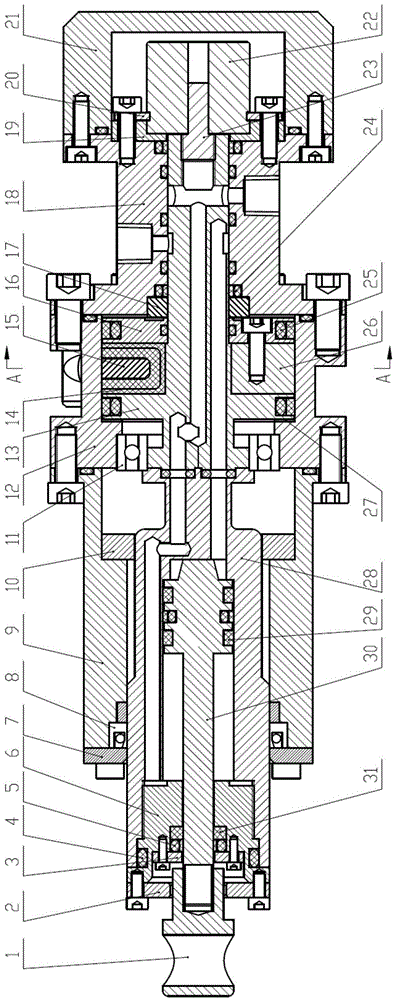

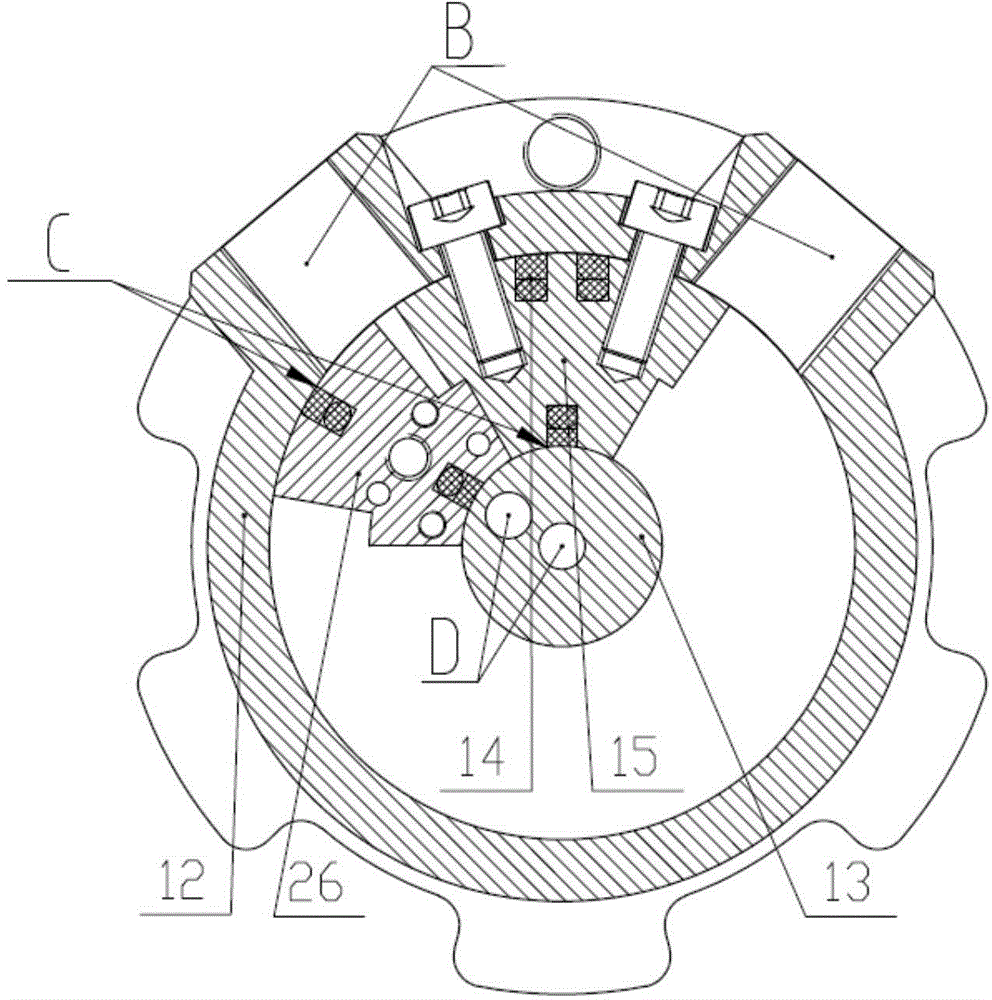

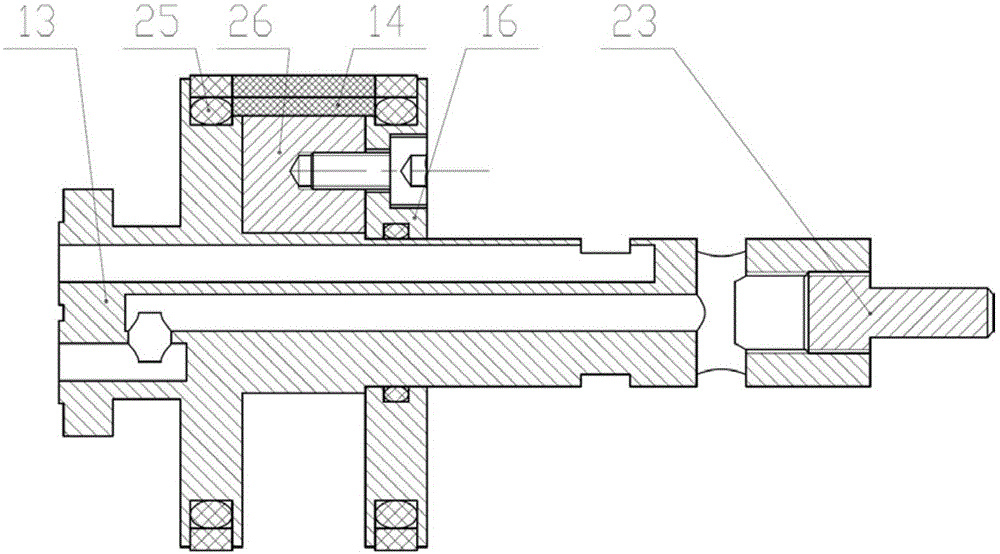

[0022] combine Figure 1-7 , the purpose of the present invention is achieved in this way: the two-stage drive joint includes a first-stage linear motion paw-driven hydraulic cylinder assembly, a second-stage joint rotation assembly, a position detection assembly, and the rear end of the first-stage hydraulic cylinder assembly is connected to the second stage. The front end of the first-level wrist joint is connected by screws, the oil circuit inside the component is sealed by an O-ring, and the position detection component is in interference fit with the rear-end support shaft of the second-level wrist joint; through the oil inlet / outlet in the middle of the second-level joint mechanism The hydraulic oil at the port drives the wrist joint to rotate and drives the first-stage hand hydraulic cylinder assembly to rotate together, and the hydraulic oil at the inlet / o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com