Condensation type fuel gas heating stove

A gas heating and condensing technology, used in air heaters, lighting and heating equipment, fluid heaters, etc., can solve problems such as maintaining constant value, energy waste, and efficiency drop, reducing excess air coefficient and increasing dew point temperature. , the effect of increasing the condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

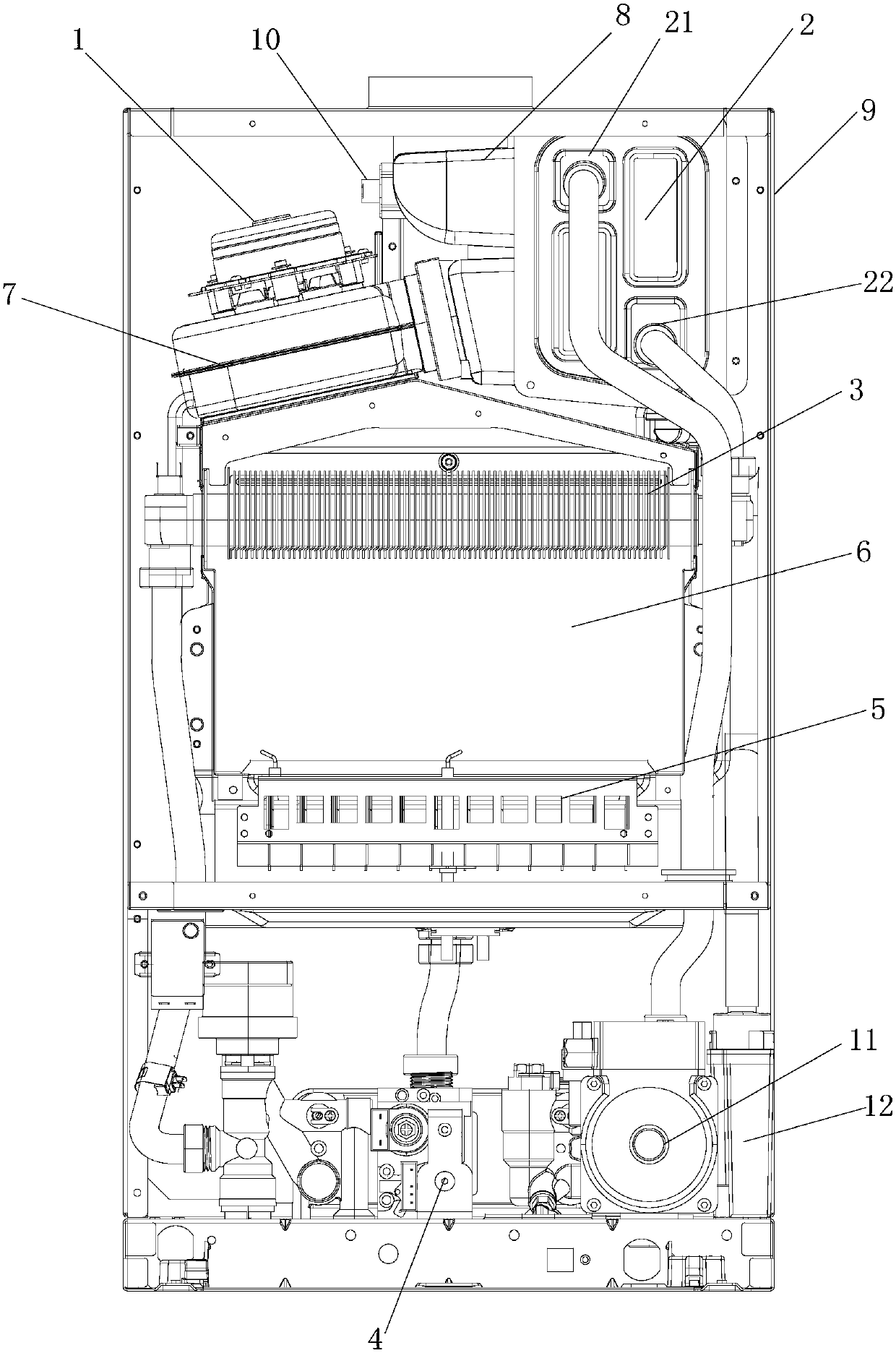

[0032] like figure 1Shown is a structural schematic diagram of a condensing heating furnace. The gas condensing dual-purpose heating furnace described in this embodiment, which can precisely control the air volume and increase the condensation effect, is an "IP" type gas heating and hot water equipment, which can provide two water supplies for domestic water and heating water. One road is for domestic water supply, which directly uses the combustion heat of combustible energy to heat water, and then provides the heated hot water to users, which is mainly used in daily life; the other road is for heating water, which is used to increase the temperature of the heating space. The heating water channel in the heating furnace is connected to the water channel in the heating space: the heating furnace heats the heat exchange medium (here is liquid water), and then the heated high-temperature heat exchange medium communicates with the external medium through the medium such as the pi...

Embodiment 2

[0040] This embodiment is a further limitation of the first embodiment above. The waste heat recovery device 2 is provided with a water inlet 21 and a water outlet 22 . The water inlet 21 is connected to the circulating water pump 11 , and the water outlet 22 is connected to the main heat exchanger 3 . And the level of the water outlet 22 is lower than that of the water inlet 21 to facilitate the liquid to flow out. The liquid inside the system (i.e. heat exchange medium) first enters the waste heat recovery device 2 through the water inlet 21 through the circulating water pump 11, and enters the main heat exchanger 3 through the water outlet 22 after exchanging heat with low-temperature flue gas in the waste heat recovery device 2. One end of the main heat exchanger 3 is connected to the water outlet 22 of the waste heat recovery device 2, and the other end is connected to the hot water outlet. The liquid inside the system exchanges heat with the high-temperature flue gas in ...

Embodiment 3

[0042] This embodiment is a further limitation of the above-mentioned first embodiment: the electric control board of the DC fan is separated from the fan body 1, and the electric control board can work normally after being installed in an area where the temperature limit of the electric control board components is allowable. Compared with the fan electric control board, the fan body 1 can adapt to a wider temperature range, and after eliminating the influence of the environmental adaptability of the fan electric control board, the heating furnace of the DC fan can be applied to work in harsh environments. Preferably, the fan electric control board of the DC fan is integrated with the overall electric control board of the heating furnace, and the centralized design of the electric control board makes the external control operation more convenient and simple.

[0043] Preferably, there is no induction element in the fan body 1. During the working process of the heating furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com