Intelligent control method of deep cone thickener under filling scene

A technology of deep cone thickener and intelligent control, which is applied in separation methods, chemical instruments and methods, wet separation, etc., and can solve the problems of relying on manual experience and lack of self-adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

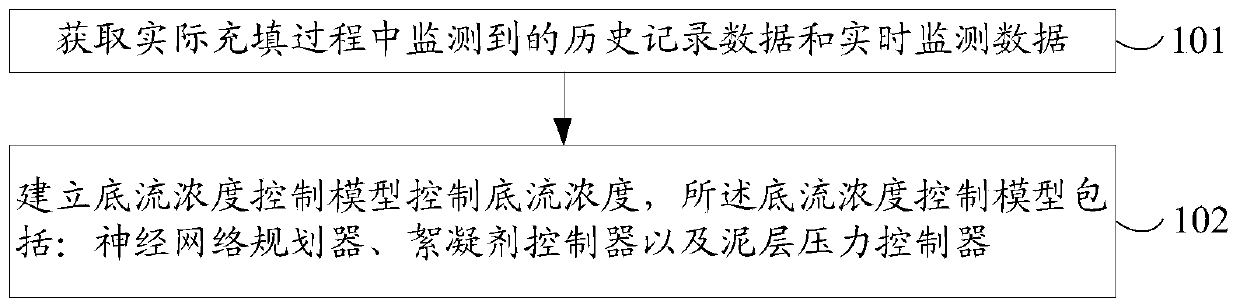

[0068] like figure 1 As shown, the intelligent control method of the deep cone thickener under the filling scene provided by the embodiment of the present invention includes:

[0069] S101, acquiring historical record data and real-time monitoring data monitored during the actual filling process;

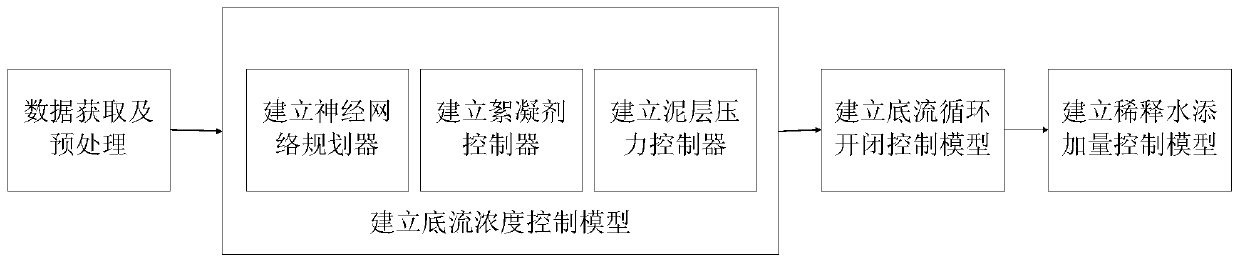

[0070] S102, establishing an underflow concentration control model to control the underflow concentration and overflow water turbidity, the underflow concentration control model includes: a neural network planner, a flocculant controller, and a mud layer pressure controller; wherein,

[0071] The neural network planner is trained offline through historical record data, and the underflow concentration target value and overflow water turbidity warning line value are input into the trained neural network planner, and the neural network planner outputs the optimal rake speed setting value, flocculant addition ratio and mud layer pressure setting value;

[0072] The flocculant controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com