Patents

Literature

41results about How to "Real-time monitoring status information" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for long-distance collection and diagnosis treatment of vehicle-mounted equipment status

InactiveCN106335523AImprove operational safetyReal-time monitoring of operating parametersSignalling indicators on vehicleThe InternetMonitoring system

The invention belongs to the technical field of railway carriage equipment diagnosis, and relates to a method for long-distance collection and diagnosis treatment of a vehicle-mounted equipment status. The method adopts a cloud platform-based remote wireless monitoring system to monitor the information of the vehicle-mounted equipment status in real time. The cloud platform-based remote wireless monitoring system comprises a vehicle-mounted equipment detection module, a data communication terminal and an internet cloud platform. The cloud platform-based remote wireless monitoring system can monitor the operating parameter and status information of a vehicle in real time and realize the on-line intelligent diagnosis and long-distance acceptance of status and fault information to discover the failure of vehicle-mounted equipment timely and rapidly and to transmit the failure to relevant units quickly and accurately, thereby minimizing the maintenance time, reducing the equipment failure rate and improving the operation safety of trains.

Owner:CRRC NANJING PUZHEN CO LTD

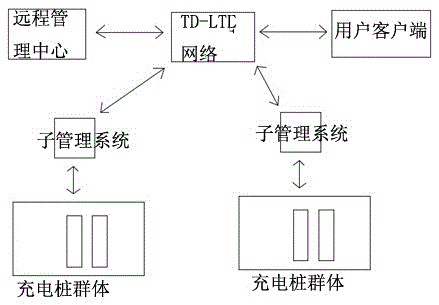

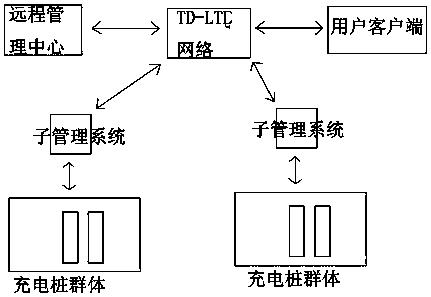

Intelligent guide charging system of new energy vehicle

InactiveCN105620303AScientific and effective managementImprove management efficiencyCharging stationsMobile unit charging stationsNew energyComputer terminal

The invention discloses an intelligent guide charging system of a new energy vehicle. The system comprises a charging pile group, a sub management system, a remote management center and a user client terminal; the charging pile group is connected with the sub management system through a CAN bus; the sub management system is provided with a LPE-CPE terminal, and is connected to a TD-LTE network through the LPE-CPE terminal; the remote management center performs data exchange with the sub management system and the user client terminal through the TD-LTE network; the charging pile group includes multiple independent charging piles; the independent charging piles are connected with the CAN bus, and are provided with unique MAC codes; the positions of the independent charging piles are fixed; the position information of the independent charging piles is recorded in the sub management system and the remote management system; the sub management system acquires use states of the independent charging piles in real time, and transfers the information to the remote management center; the user client terminal can obtain the use states and the position information of the independent charging piles at any time; and the user client terminal can guide users to reach the selected positions of the independent charging piles.

Owner:JIANGSU GUOAI ELECTRIC CO LTD

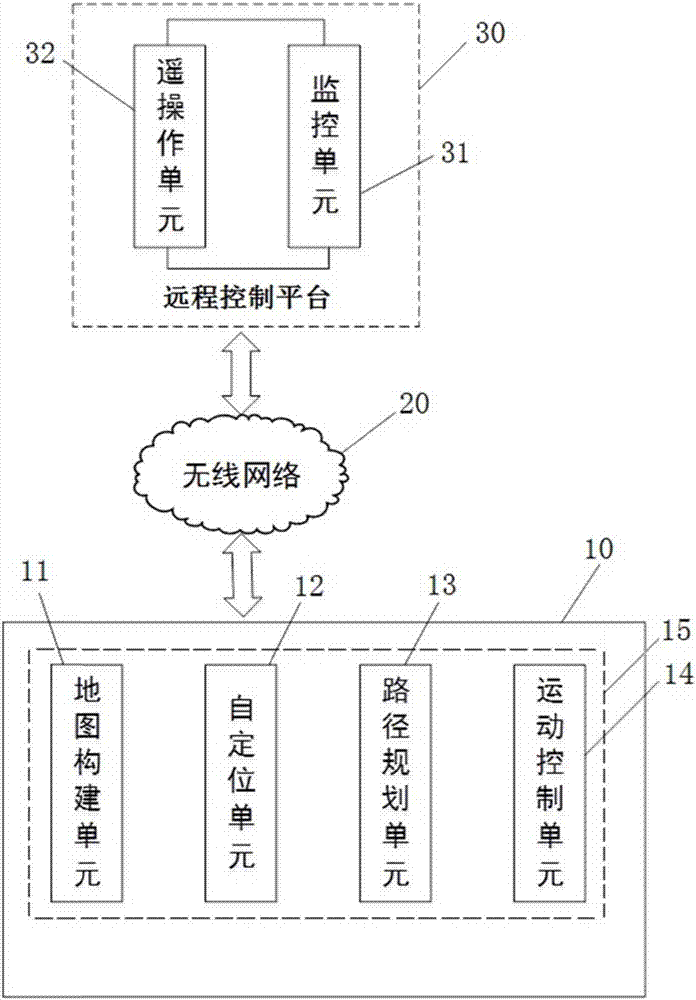

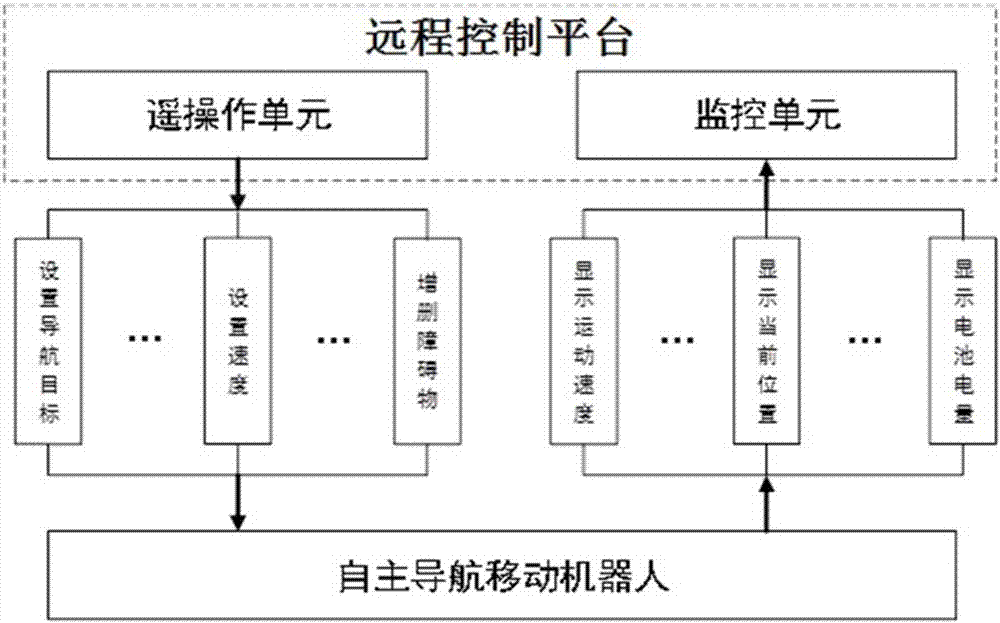

Robot automatic navigation system

PendingCN106886219AWith teleoperationPositioningPosition/course control in two dimensionsSimulationLaser sensor

The invention provides a robot automatic navigation system. The system comprises a remote control platform and an autonomous navigation module which communicate with each other. The autonomous navigation module is arranged inside a robot. The autonomous navigation module comprises a map building unit which builds an environmental map by getting data of a laser radar sensor and an odometer, a self-positioning unit which matches sensing information of a laser ranging sensor with the environmental map to get the actual location information of a robot in an environment, a route planning unit which receives observed data of the laser sensors passing through the self-positioning unit, updates the map and plans a route according to the current location of the robot and a target location set by the remote control platform, and a motion control unit which carries out route tracking according to a route planned by the route planning unit. The advantage lies in that man-machine work can be better coordinated, and heavy work in a complex environment can be completed more efficiently.

Owner:上海悦合自动化技术有限公司

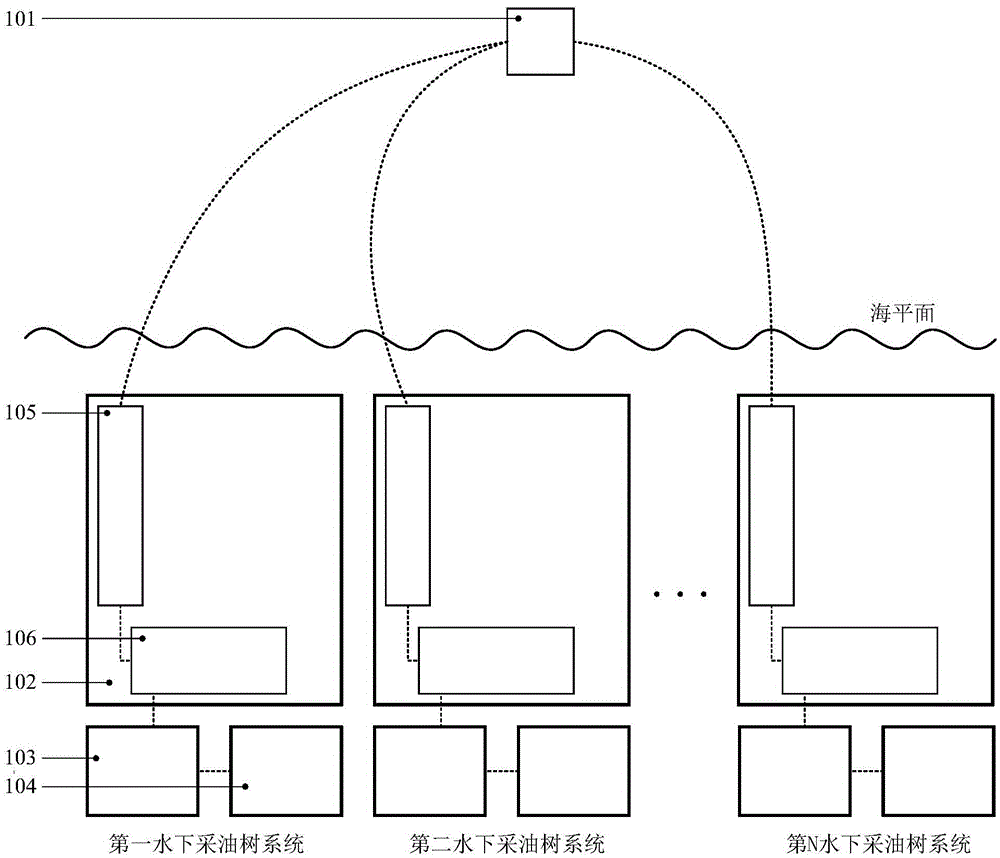

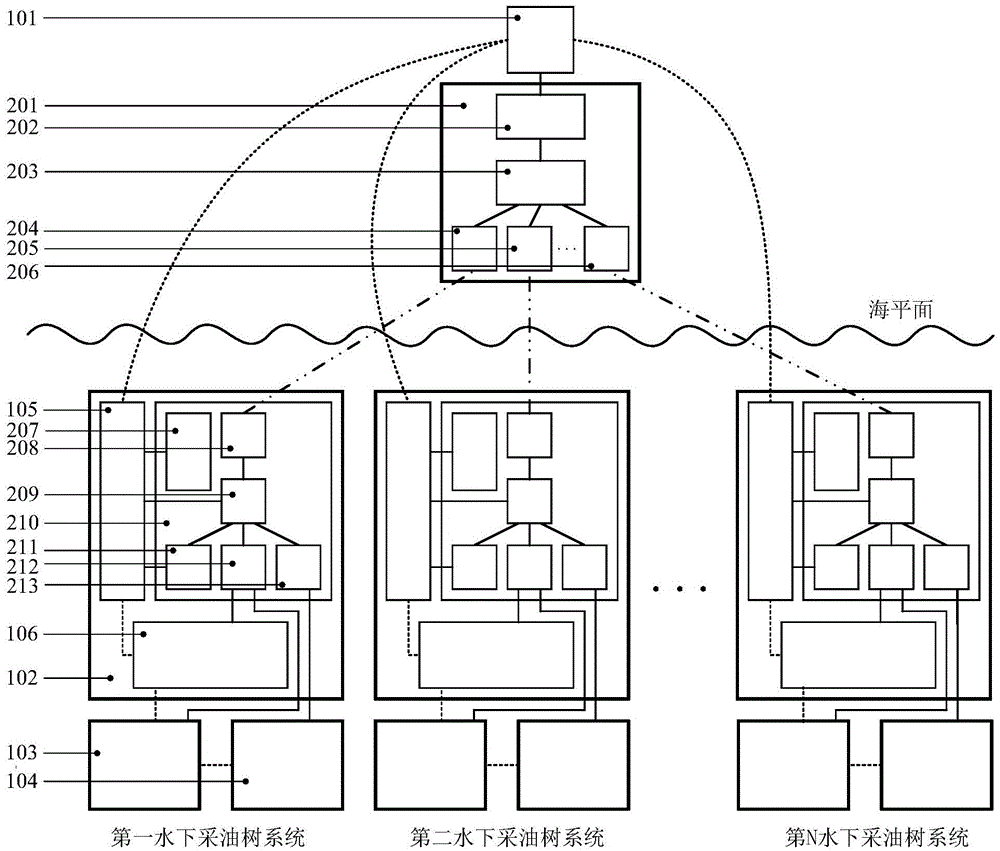

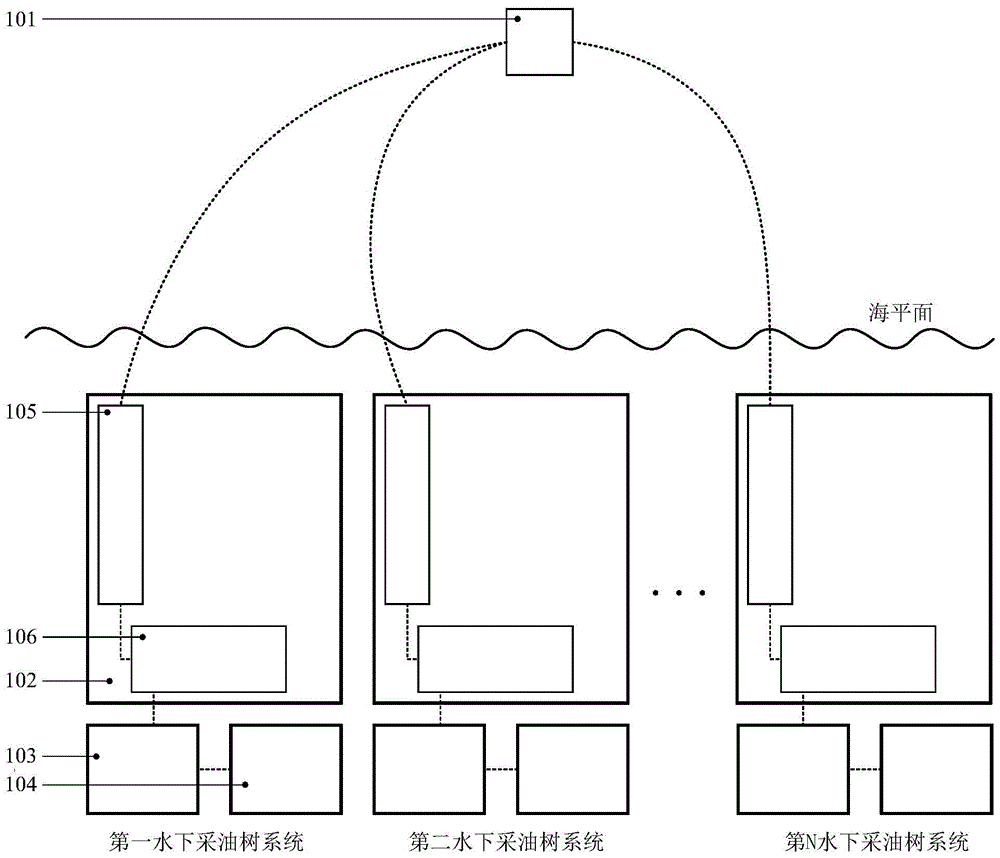

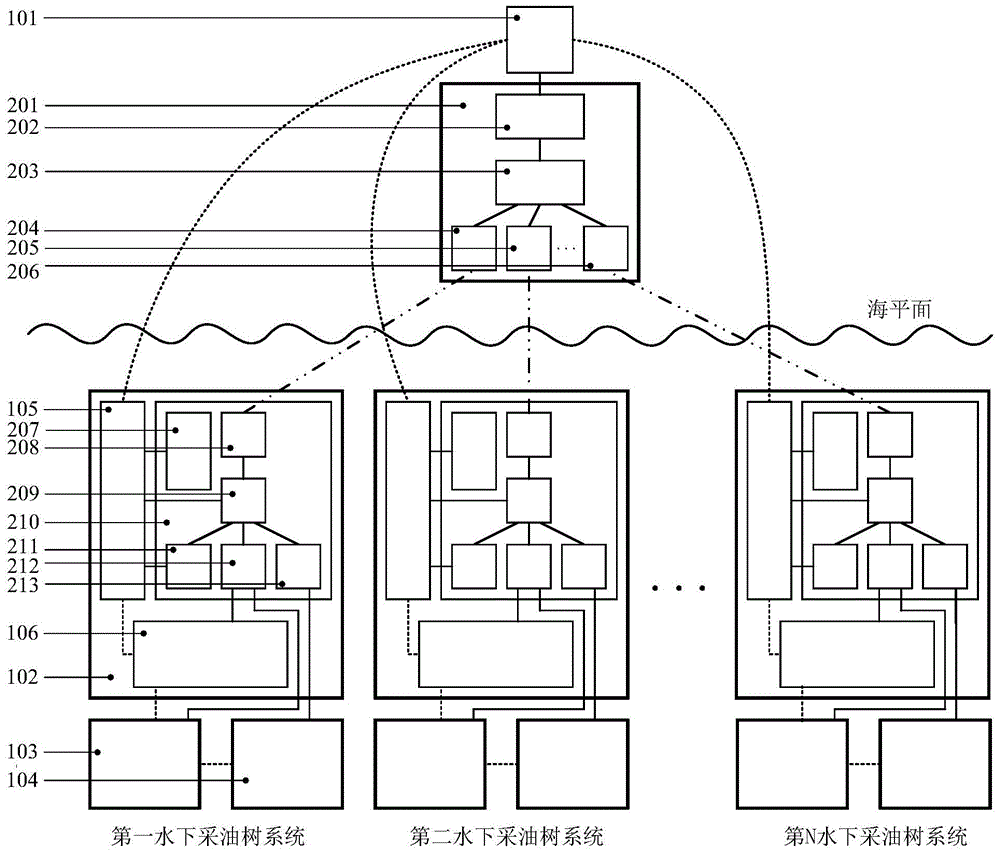

Intelligent monitoring and dynamic fault diagnosis system for subsea tree

ActiveCN105634819AReal-time monitoring status informationImprove securityNon-electrical signal transmission systemsData switching networksSonarData acquisition

The invention belongs to the field of petroleum engineering and particularly relates to an intelligent monitoring and dynamic fault diagnosis system for a subsea tree. The intelligent monitoring and dynamic fault diagnosis system for the subsea tree comprises signal reception and fault diagnosis sub-systems and data acquisition and sonar signal emission sub-systems, wherein the signal reception and fault diagnosis sub-systems are located in a control room on a drilling platform, and the data acquisition and sonar signal emission sub-systems are located in undersea control modules; one data acquisition and sonar signal emission sub-system is arranged in each undersea control module; and data transmission between the signal reception and fault diagnosis sub-systems and data acquisition and the sonar signal emission sub-systems is carried out through sonar. According to the intelligent monitoring and dynamic fault diagnosis system for the subsea tree, the status information of multiple undersea tree systems can be monitored in real time and be respectively emitted to an offshore oil platform through sonar signals to carry out comprehensive diagnostic analysis, so that the safety for marine petroleum exploitation is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

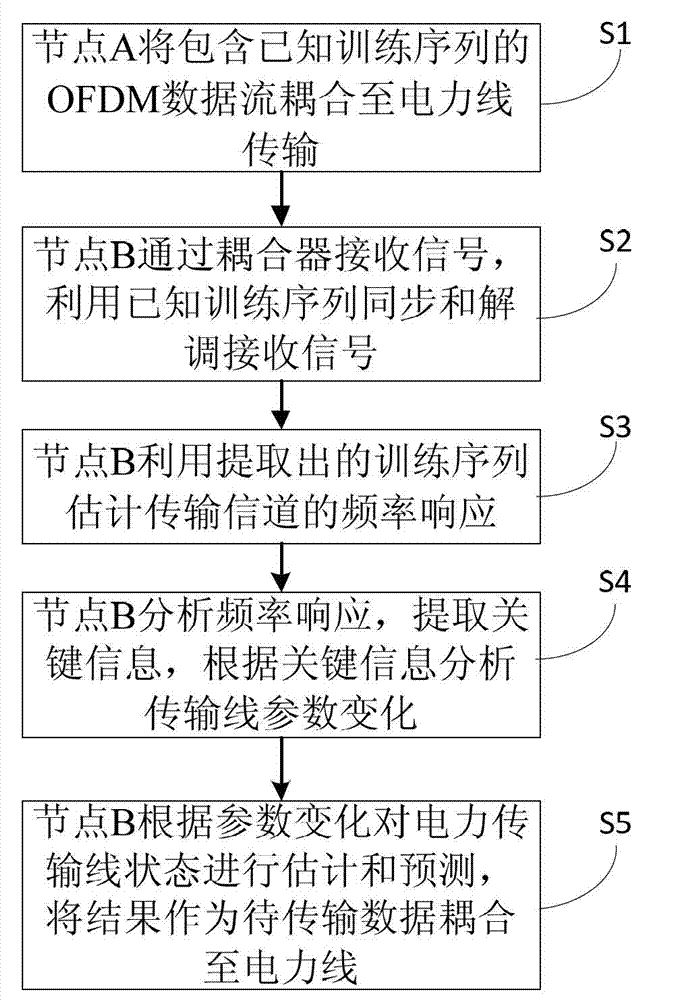

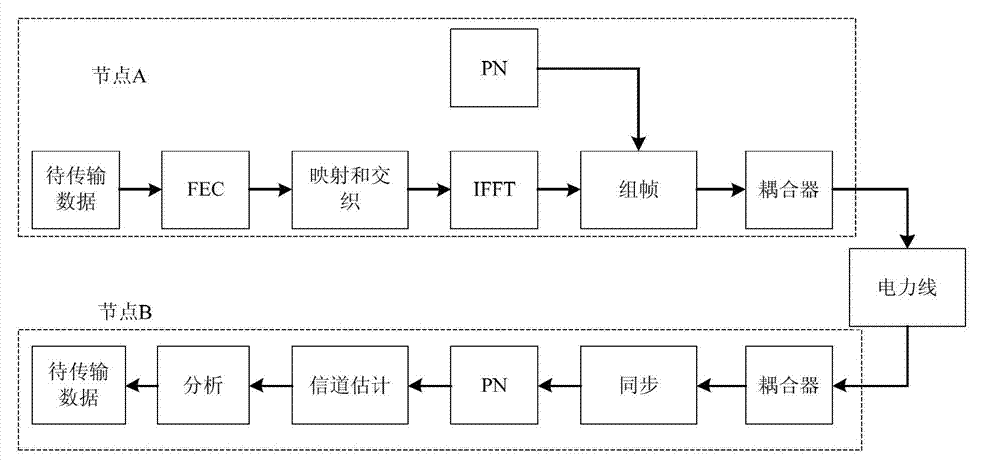

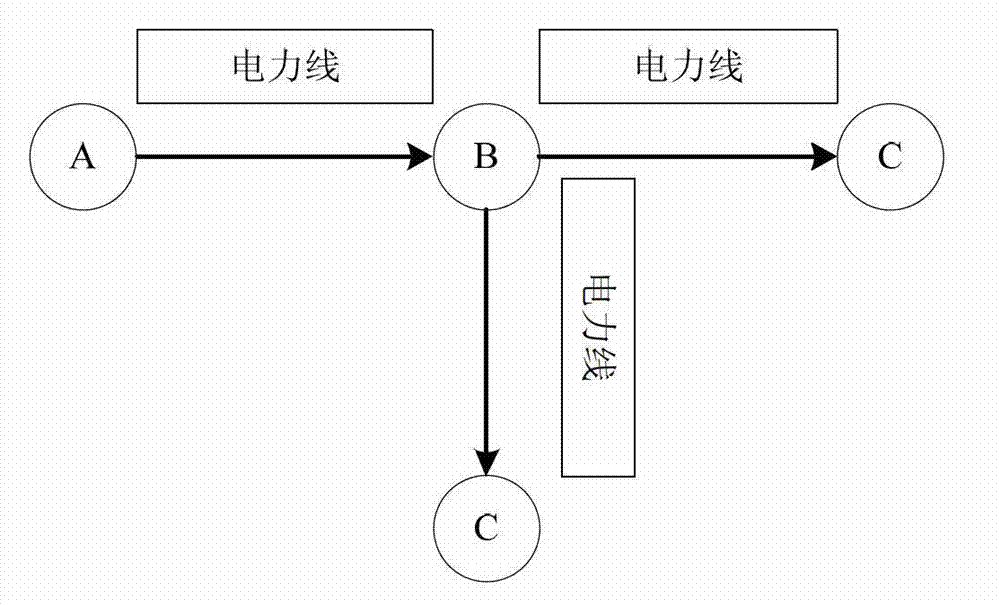

Power line state monitoring method and device

InactiveCN102832970AReal-time monitoring status informationLow costMulti-frequency code systemsLine-transmission monitoring/testingChannel parameterPower-line communication

The invention provides a monitoring method of a power transmission line state in a power line communication system, wherein the monitoring method comprises the following steps: S1. a node A performs framing on the known training sequence and to-be-sent data modulated by an OFDM (orthogonal frequency division multiplexing) technology, and sends signals into a power line through a coupler for transmission; S2. a node B receives sent signals through the coupler, modulates the received signals by utilizing the known training sequence, and extracts transmission data; S3. the node B obtains transmission channel frequency response or impact response by utilizing the known training sequence; S4. the node B analyzes the channel frequency response, extracts relevant information of the transmission line, and obtains the variation information of basic parameters of the transmission line through analyzing the relevant information so as to calculate the channel parameters; and S5. the node B estimates and forecasts the channel state of the power transmission line according to channel parameter variation. According to the method provided by the invention, the state information of the power line can be monitored in real time, and a data collecting device and a communication system are not required to be arranged out of the power transmission line, and the monitoring method of the power transmission line state in the power line communication system has the advantages of good stability, low cost, and the like.

Owner:TSINGHUA UNIV +1

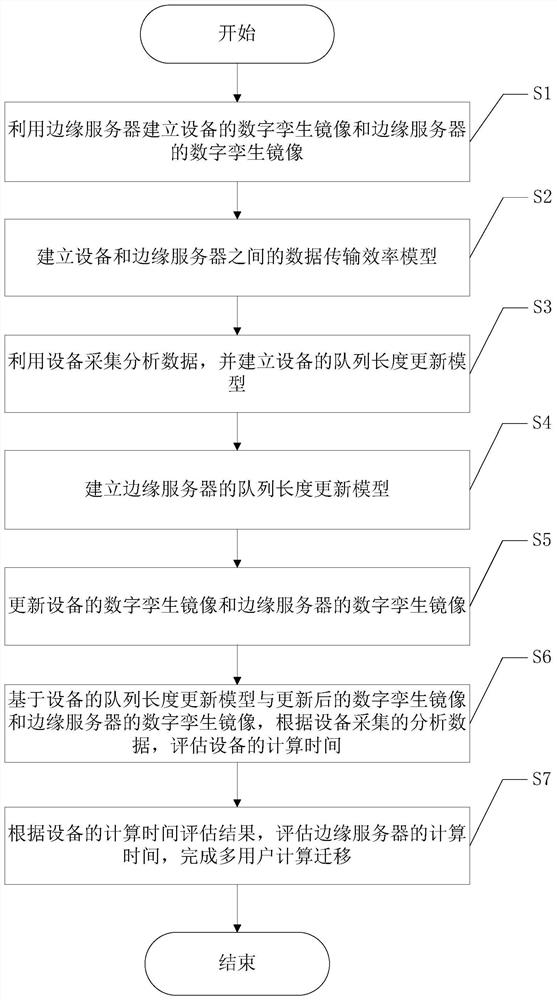

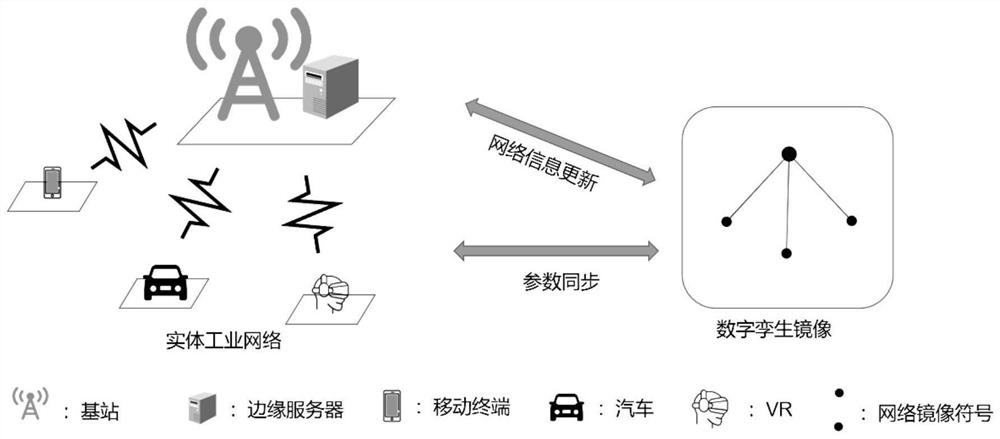

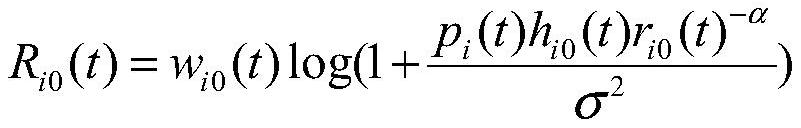

Multi-user computing migration method based on digital twinning technology

The invention discloses a multi-user computing migration method based on a digital twinning technology. The multi-user computing migration method comprises the following steps: S1, establishing a digital twinning mirror image of equipment and a digital twinning mirror image of an edge server; S2, establishing a data transmission efficiency model between the equipment and the edge server; S3, establishing a queue length updating model of the equipment; S4, establishing a queue length updating model of the edge server; S5, updating the digital twin mirror image of the equipment and the digital twin mirror image of the edge server; S6, evaluating the calculation time of the equipment; and S7, evaluating the calculation time of the edge server, and completing multi-user calculation migration. The invention provides a set of effective computing migration method for solving the problem that data computing cannot be completed on time due to insufficient computing resources of equipment, and the online method is more reasonable in an actual scene, stronger in operability and better in effectiveness due to the fact that the traditional single equipment does not have universality when executing a single task and is not suitable for the industrial Internet of Things.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

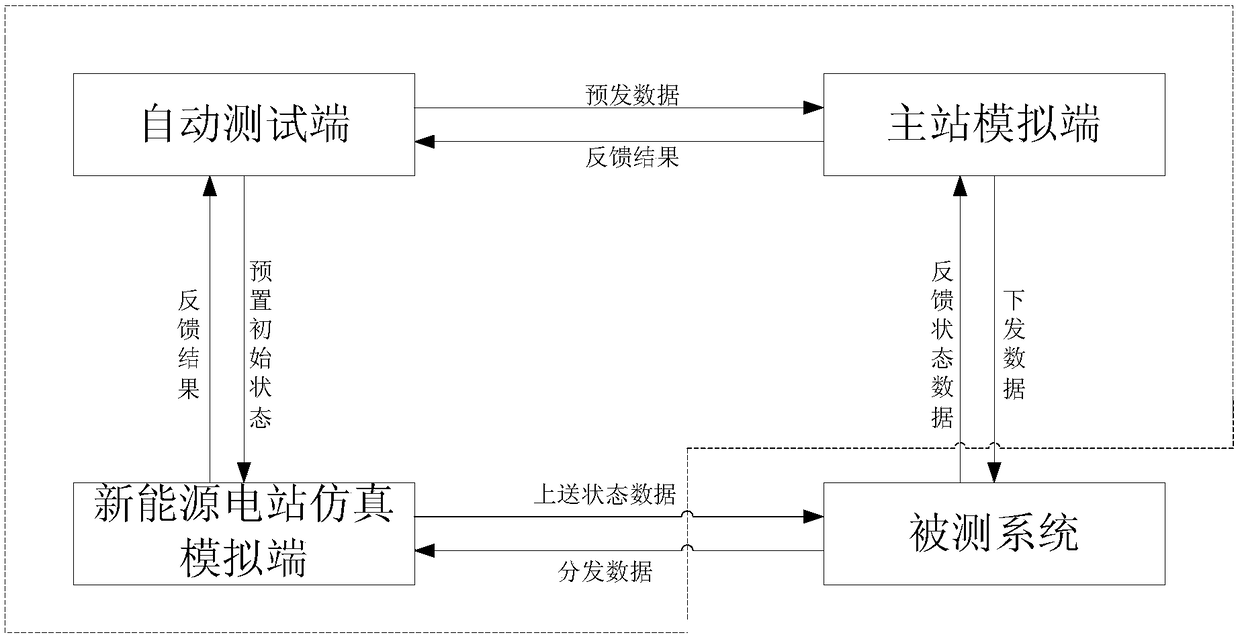

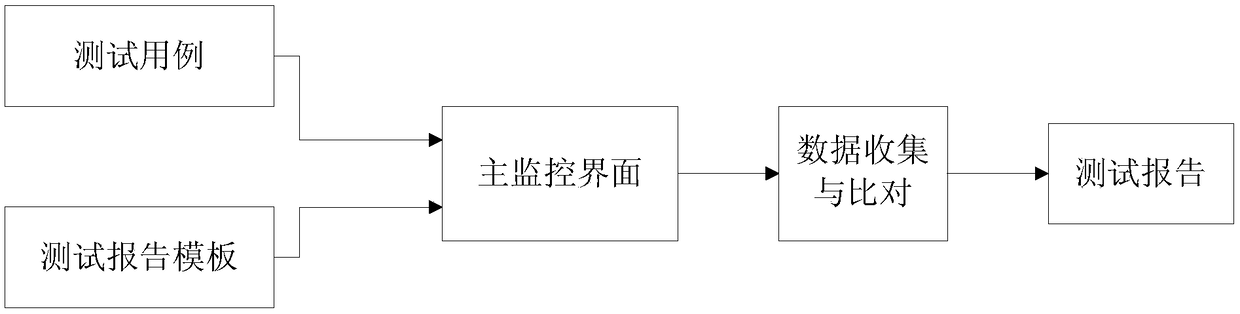

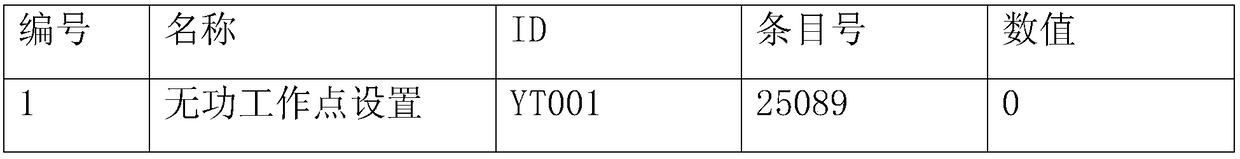

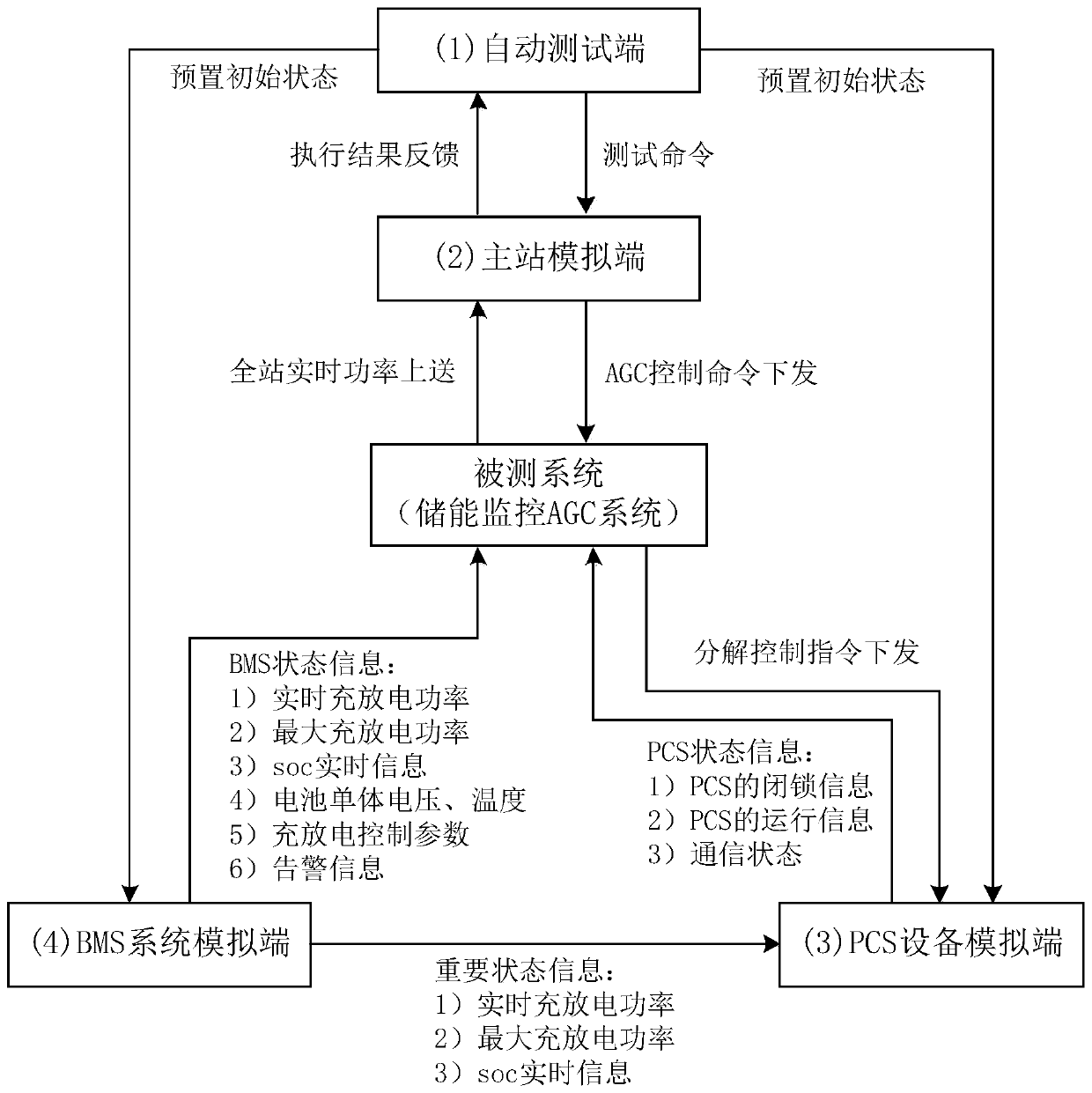

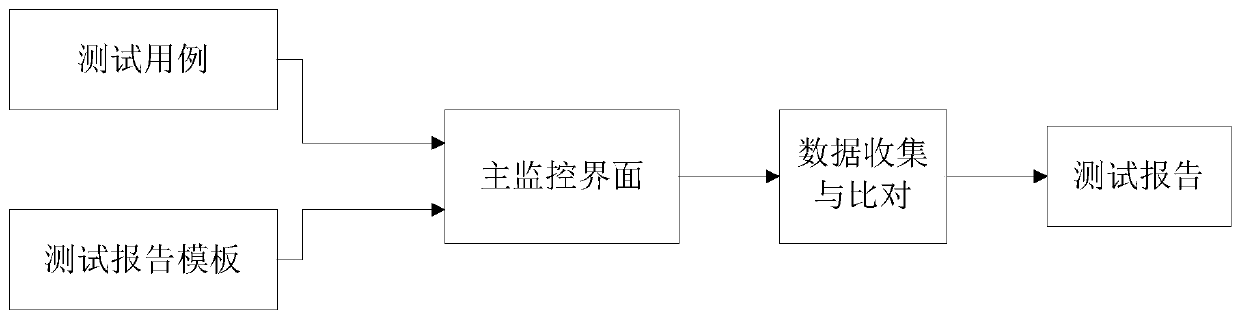

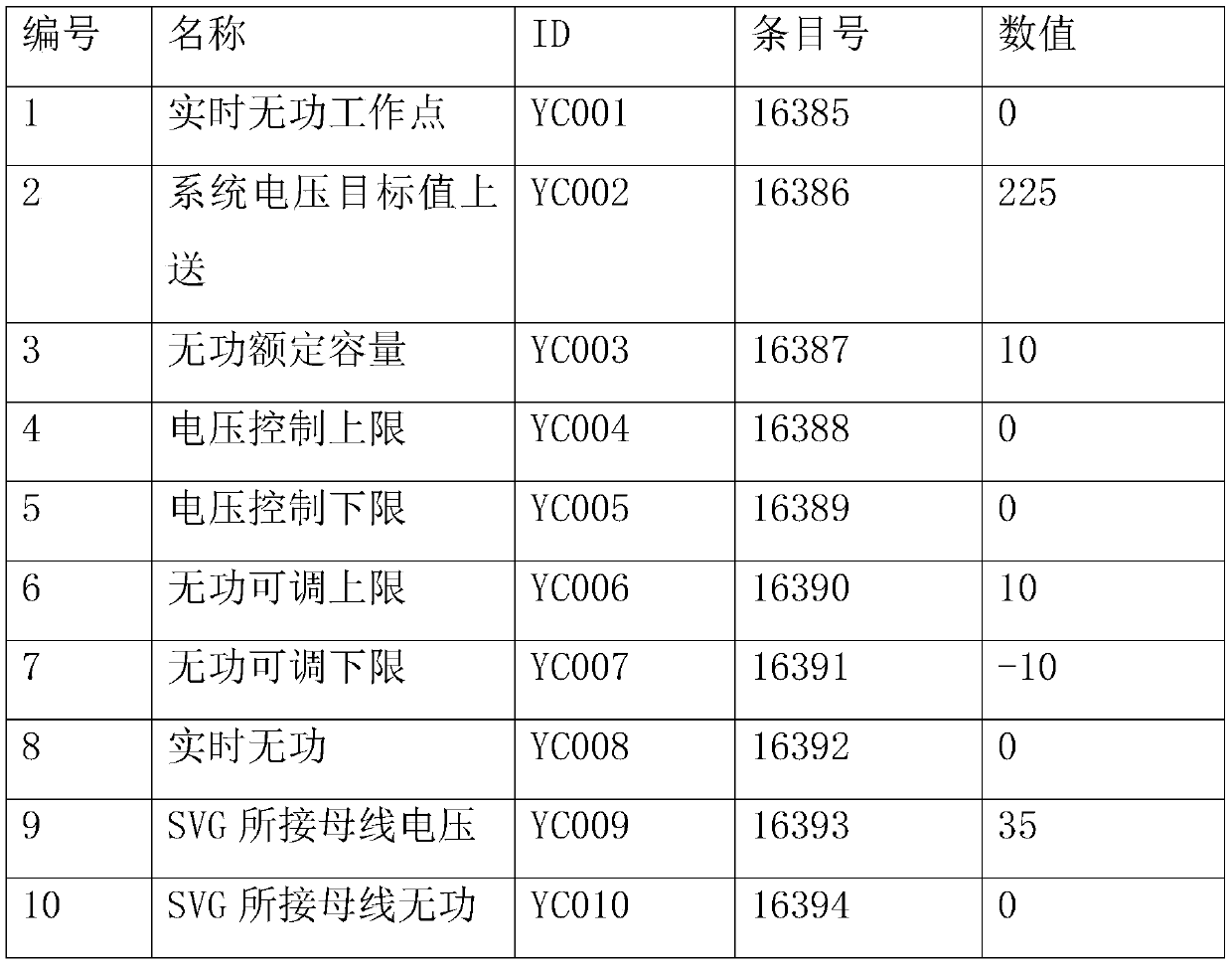

Automatic detection system and method for new energy AGC or AVC control system

ActiveCN108958216AReduce difficultyImprove adaptabilityElectric testing/monitoringTest complexityAutomotive engineering

The invention discloses an automatic detection system and method for a new energy AGC or AVC control system. The detection method comprises steps that (1), a device model of a new energy power stationis modeled, and initial state parameter values of new energy power station devices are set; (2), an active or reactive target value is issued by a main station simulation end to a detected system according to the target value information notified by an automatic test end through a com interface; (3), an instruction is received by the detected system, after calculation, remote adjustment or remotecontrol instructions are transmitted to all the devices in the simulation end of the new energy power station; (4), values of parameters of each device needing adjusted according to the instructionsare adjusted according to the received instructions and the initial state by the simulation end of the new energy power station, the result is fed back to the detected system, and the automatic test end is further informed; and (5), feedback result data of the simulation end of the new energy power station is received by the automatic test end and is written into a test report. The detection method is advantaged in that the closed loop simulation test of the detected system is performed, test complexity is reduced, and test efficiency is improved.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION

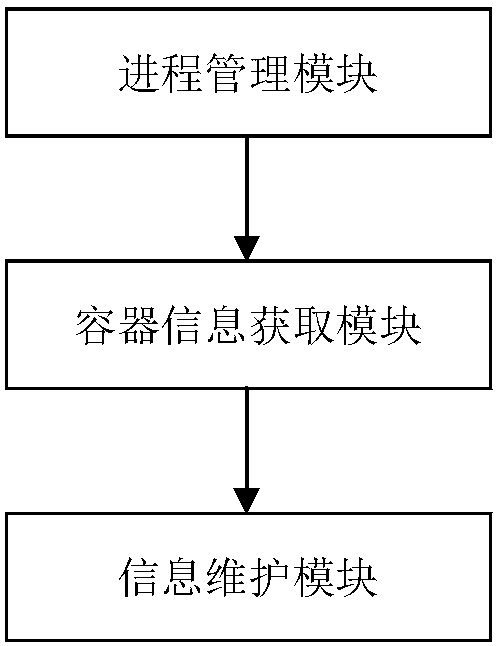

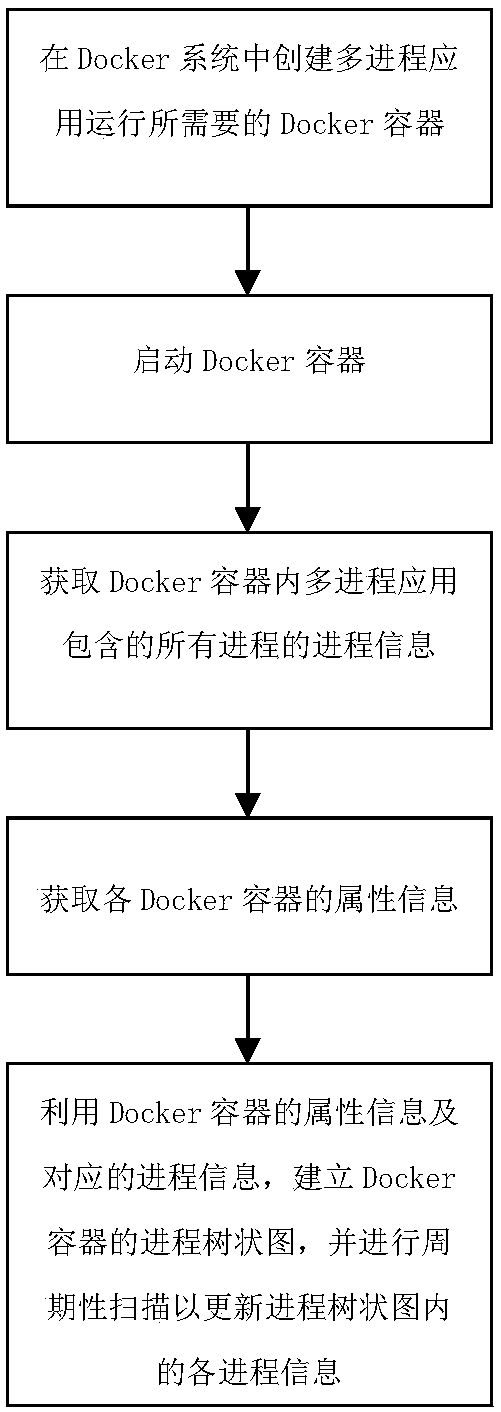

Docker container multi-process management method and system

InactiveCN108121595ASolve multi-process management problemsReal-time monitoring status informationProgram initiation/switchingResource allocationEngineeringParent process

The invention provides a Docker container multi-process management method and system. The system comprises a process management module, a container information obtaining module and an information maintenance module. By utilizing the Docker container multi-process management method and system provided by the invention, a parent process and related child processes of each application in a Docker container are managed through the arranged process management module, so that the problem of multi-process management in the Docker container is solved; and through cooperation of the container information obtaining module and the information maintenance module, state information of the processes in the Docker container can be monitored in real time, and the child processes are received and managed,so that system resources can be timely released and recovered.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +1

Automatic detection system and method for grid-side energy storage monitoring AGC control system

InactiveCN110460076AReduce in quantityLong construction periodSingle network parallel feeding arrangementsAc network load balancingFunctional testingControl system

The invention discloses an automatic detection system and method for a grid-side energy storage monitoring AGC control system. The automatic detection system includes an automatic test end, a main station simulation end, a BMS system simulation end and a PCS equipment simulation end. PCs where the automatic test end, the main station simulation end, the BMS system simulation end and the PCS equipment simulation end are located respectively and a PC where a tested energy storage monitoring AGC system is located are connected to the same switch, are configured with IEC-104 parameters, and are connected by communication. The problems of high cost, long construction period and a small number of simulation devices for the function test, pressure test and stability test environment of the grid-side energy storage monitoring AGC system as well as the difficulties in simulation of a large number of abnormal device behaviors and devices with special states and mutual cooperation between devicesin the existing method are solved.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

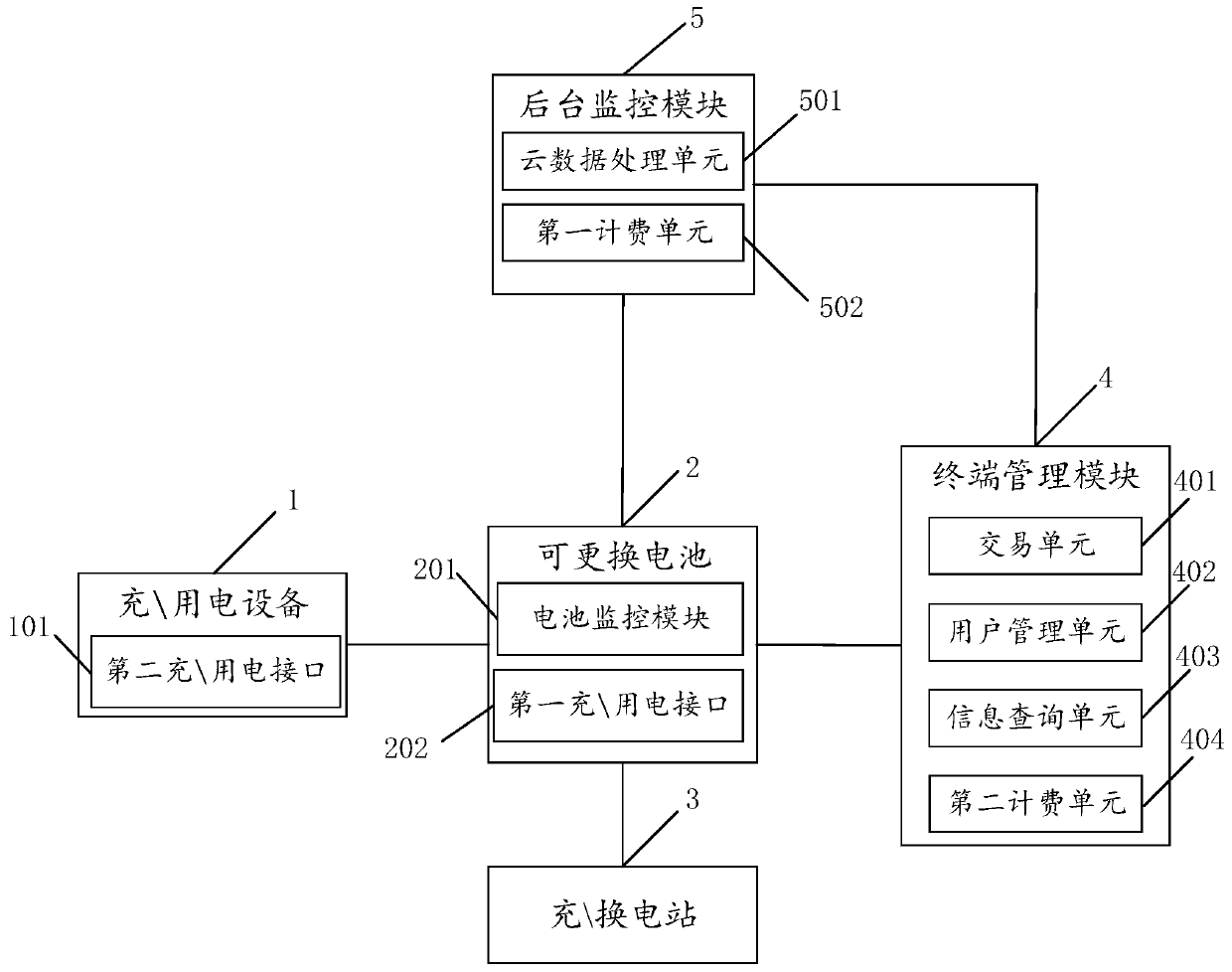

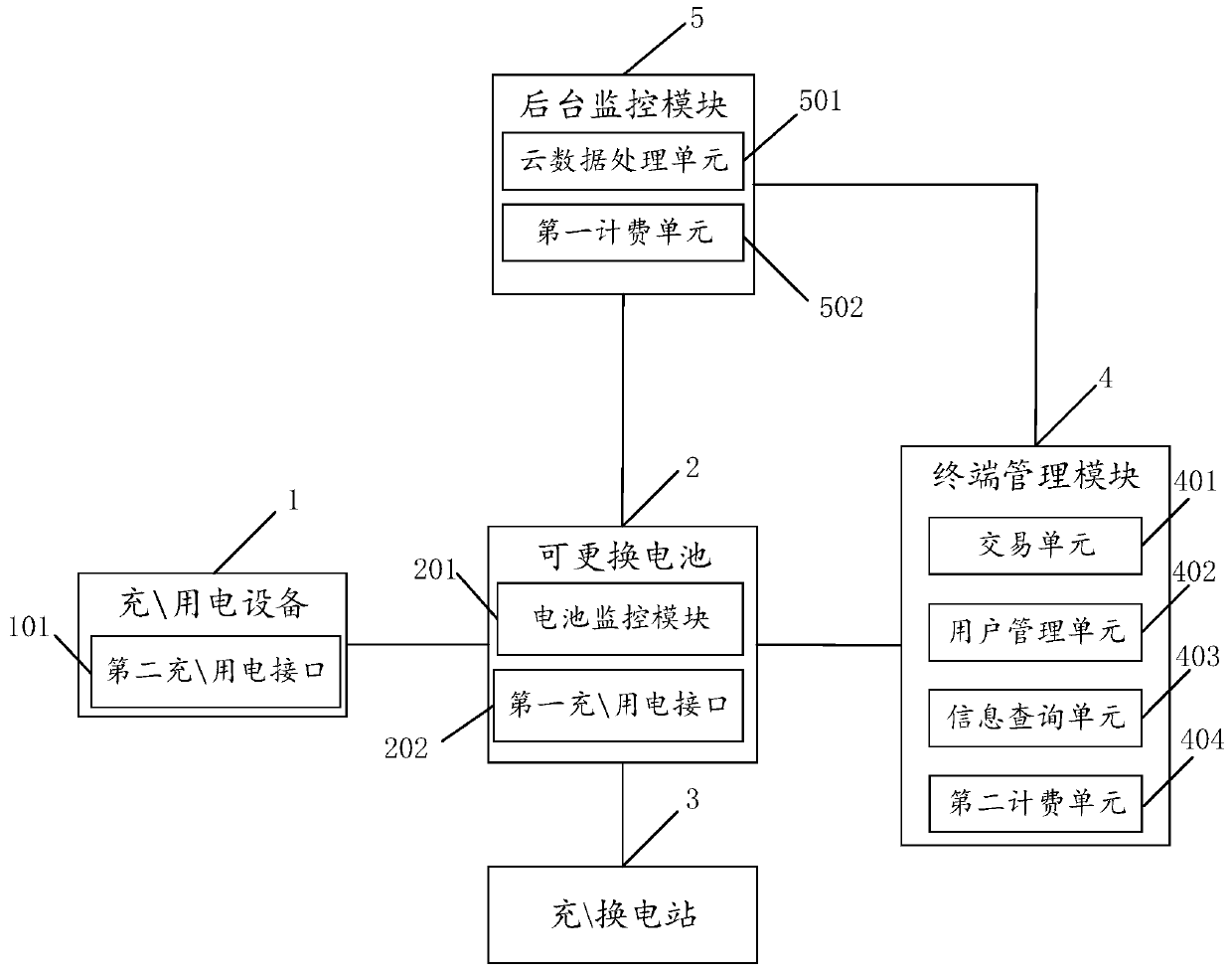

System for trading replaceable battery of electric vehicle

InactiveCN109910674AReal-time monitoring status informationSolve the problem of longevityCharging stationsElectric vehicle charging technologyElectrical batteryElectric cars

The invention discloses a system for trading a replaceable battery of an electric vehicle. The system comprises a replaceable battery, a charging station / battery replacement station, a terminal management module, a charging / power consumption device, and a background monitoring module, wherein the replaceable battery is provided with a battery monitoring module and a first charging / power consumption interface; the battery monitoring module is used for monitoring to obtain the battery status information of the replaceable battery, and performs encrypted communication with the background monitoring module; the terminal management module is used for communicating with the background monitoring module and the replaceable battery, and is used for trade operation of the replacement battery; the background monitoring module is used for receiving the battery status information of the replaceable battery, and determining the battery trade cost according to battery cost allocation, a trade location and the power of the replaceable battery. According to the system for trading the replaceable battery of the electric vehicle, the status information of the replaceable battery can be monitored inreal time, and the trade value of the battery can be accurately calculated, which is beneficial for balancing the interests of all parties involved in the trade and promoting the wide distribution ofbattery replacement stations.

Owner:玉明进

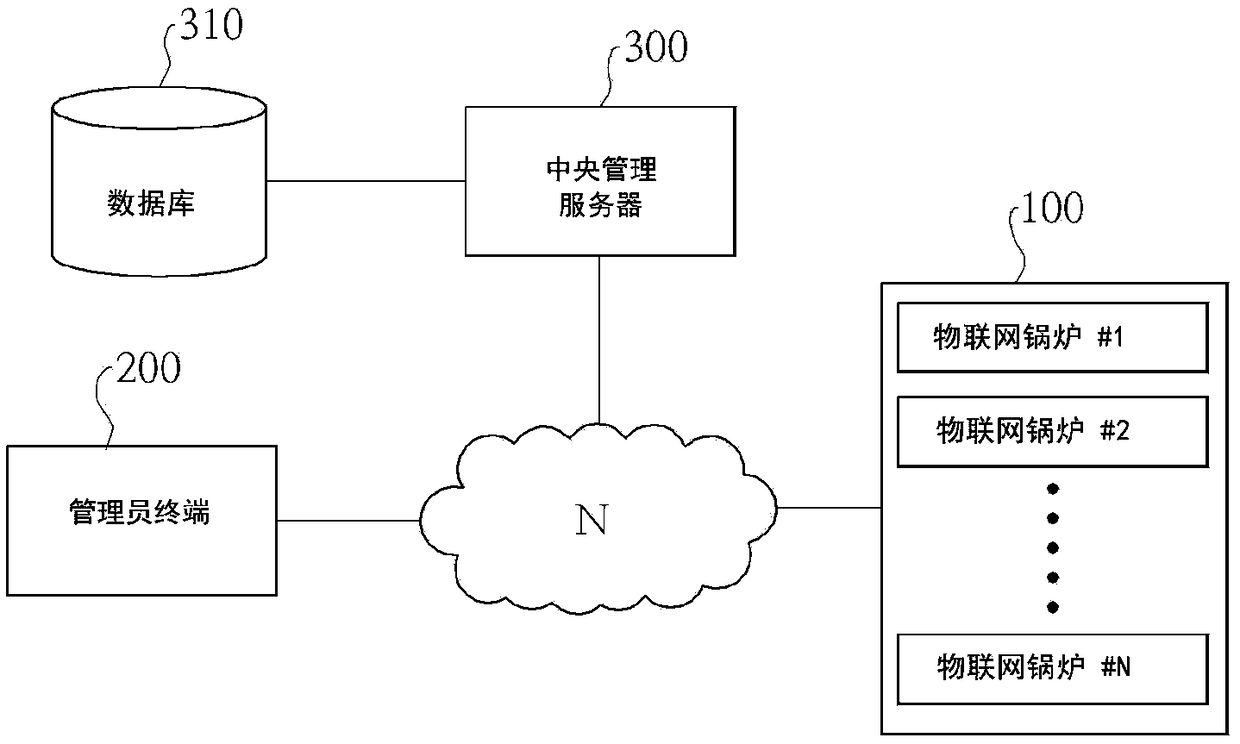

IoT SYSTEM AND METHOD FOR CONTROLLING IoT BOILER

ActiveCN108886535AReal-time monitoring status informationProgramme controlComputer controlInternet of ThingsEngineering

The present invention discloses a control system and method of an IoT boiler. The control method of an IoT boiler according to one aspect of the present invention includes an IoT boiler for checking an operation state, transmitting state information, detecting the generation of failure through a sensor, and transmitting failure information; a manager terminal which includes a boiler control application for monitoring and controlling the IoT boiler, monitors the state of the IoT boiler, receives control information for controlling the IoT boiler from a manager, and transmits it to the manager terminal; and central management server which is connected to the IoT boiler and the manager terminal via a network, receives and stores the state information of the IoT boiler periodically or non-periodically from the IoT boiler, receives control information for controlling the IoT boiler from the manager terminal, and performing the control of the IoT boiler. It is possible to quickly control theIoT boiler when the failure is generated.

Owner:KITURAMI BOILER +2

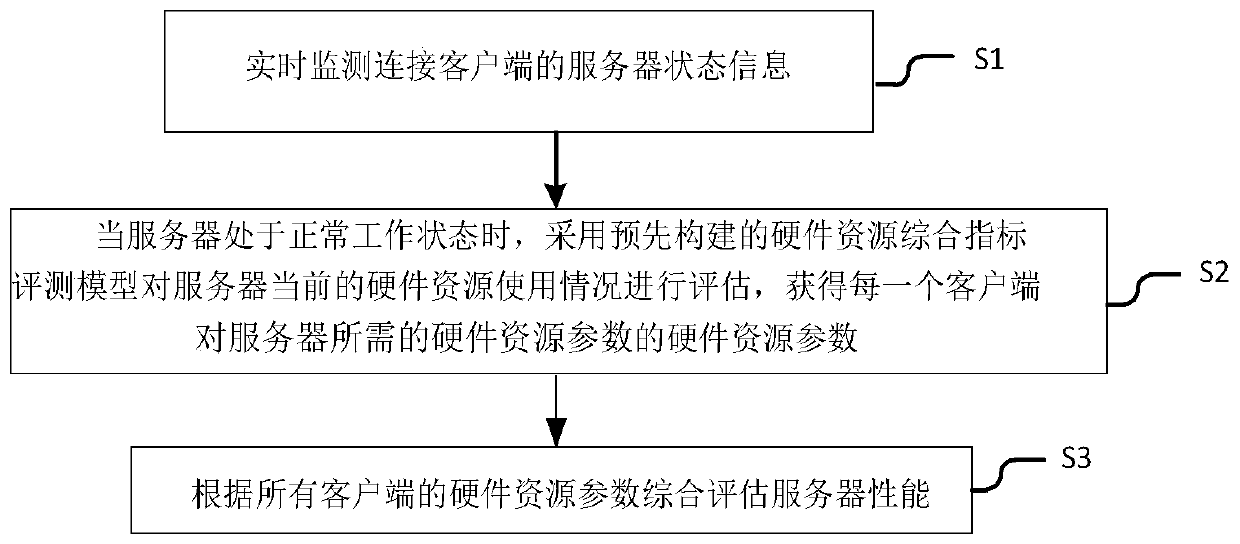

Performance evaluation method of hardware resources in specific environment

ActiveCN110633194AReal-time monitoring status informationImprove accuracyHardware monitoringEnergy efficient computingPerformance indexWork status

The invention provides a performance evaluation method for hardware resources in a specific environment. The performance evaluation method comprises the following steps: monitoring server state information connected with a client in real time; when the server is in a normal working state, evaluating the current hardware resource use condition of the server by adopting a pre-constructed hardware resource comprehensive index evaluation model to obtain hardware resource parameters required by each client; and comprehensively evaluating the performance of the server according to the hardware resource demand parameters of all the clients, wherein the hardware resource comprehensive index evaluation model comprises a server performance index used for evaluating the use condition of the server hardware resources. According to the scheme, the server performance evaluation model is effectively optimized according to the use condition of hardware resources, so that the accuracy of an evaluationresult is improved.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

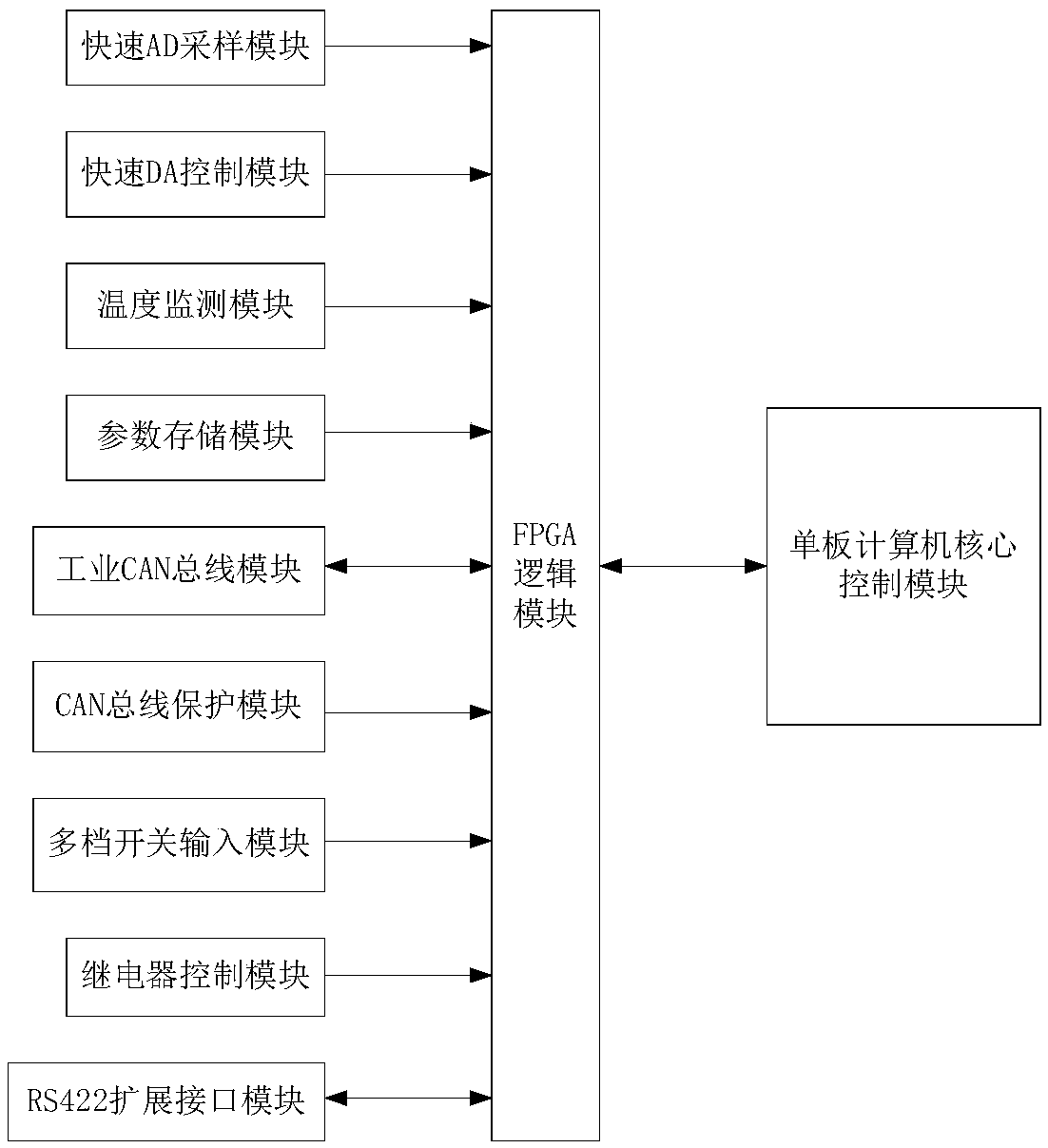

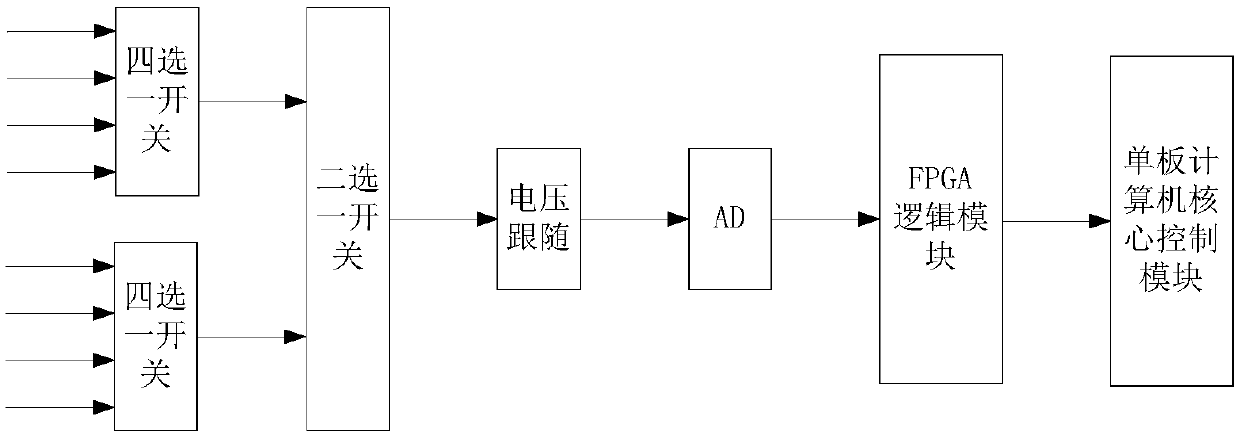

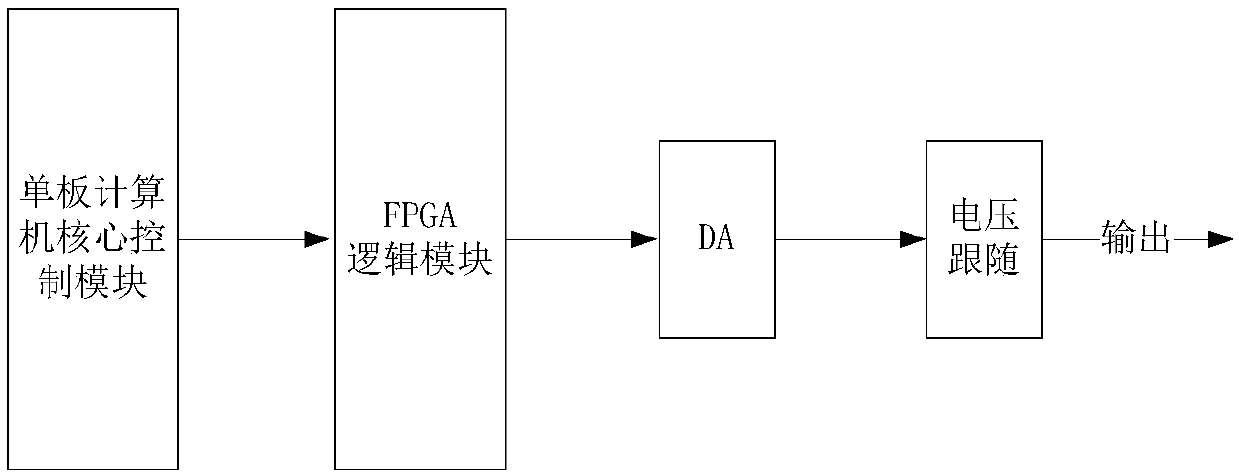

Control device, system and method for unmanned vehicle

InactiveCN109582001AReal-time monitoring status informationMeet the needs of equipment combat effectiveness inspectionElectric testing/monitoringRadarRemote control

The invention discloses a control device, system and method for an unmanned vehicle. The device comprises an FPGA logic module that is communicated with a single board computer core control module viaa cPCI bus; a fast AD sampling module collects analog data of a throttle sensor, a brake sensor and an electric appliance proportional valve, and converts the analog data into a digital quantity to be conveyed to the FPGA logic module; a fast DA control module achieves electric proportional valve control; a multi-gear switch input module achieves selection and switching of driving control modes,and the driving control modes comprise a remote control driving mode, a manned driving mode and an unmanned driving mode; and the device also comprises an industrial CAN bus module and a CAN bus protection module. The device is provided with the three driving control modes, can control the vehicles driving in the Gobi deserts and serve for troop tests, and meets the requirement that military equipment simulates the radiation property, scattering property and interference property of the enemy radar; the requirement of full process combat training of the troop is met; and the requirement of checking the operational effectiveness of missile weapon and equipment is met.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

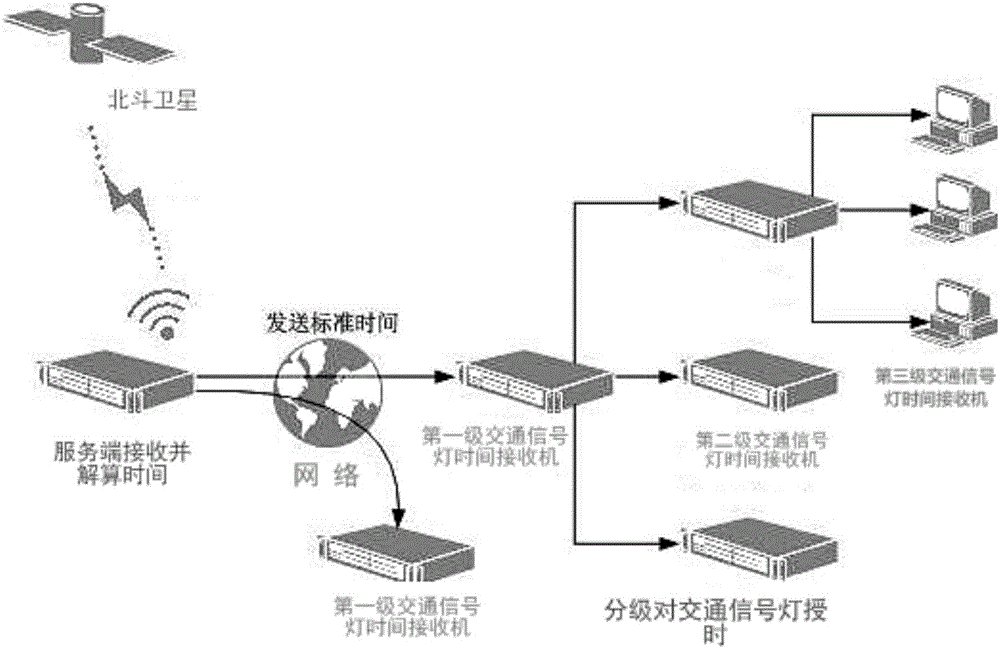

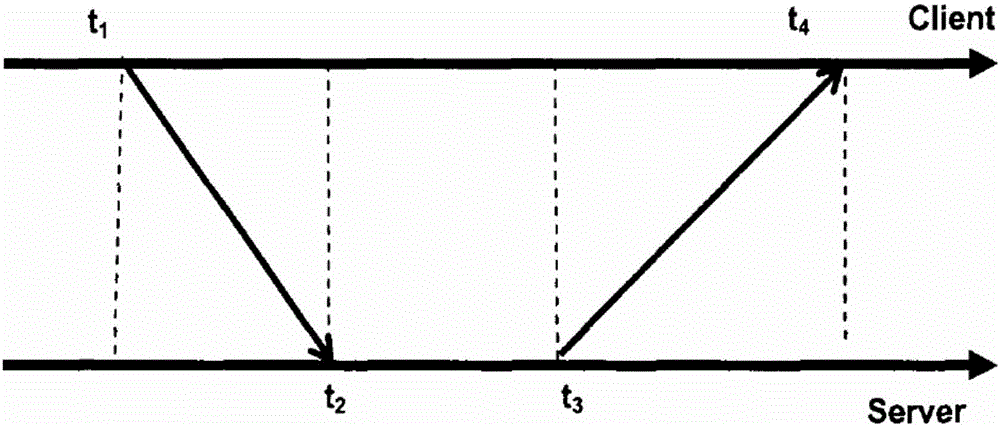

Beidou based unified time-service system device of traffic signal lamps and working method of device

ActiveCN106371310AReal-time monitoring status informationHigh precisionRadio-controlled time-piecesTime informationTraffic signal

Provided is a Beidou based unified time-service system device of traffic signal lamps. The device comprises a client and a service end; the client comprises a Beidou satellite signal reception module and an NTP server module; the NTP server module distributes time information by taking the NTP server module as an initial node, each level of traffic signal lamps has receiving and forwarding functions, and transmits time signals to the next level of traffic signal lamps, and the traffic signal lamps in the same level communicate with each other to correct time. According to the invention, the Beidou satellite and NTP time service are used to implement unified time service on the traffic signal lamps in the sparsely distributed network structure in the city, it is ensured that the traffic states of crossings in the city are monitored and managed in real time and buses take priority, and the device and method have significance in alleviating traffic jams.

Owner:SHANDONG UNIV

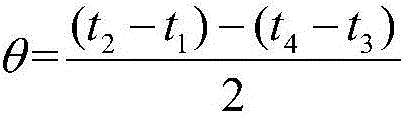

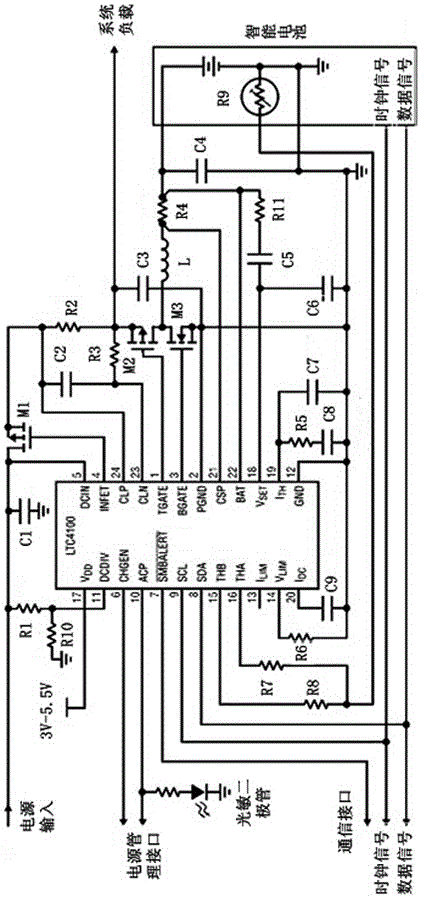

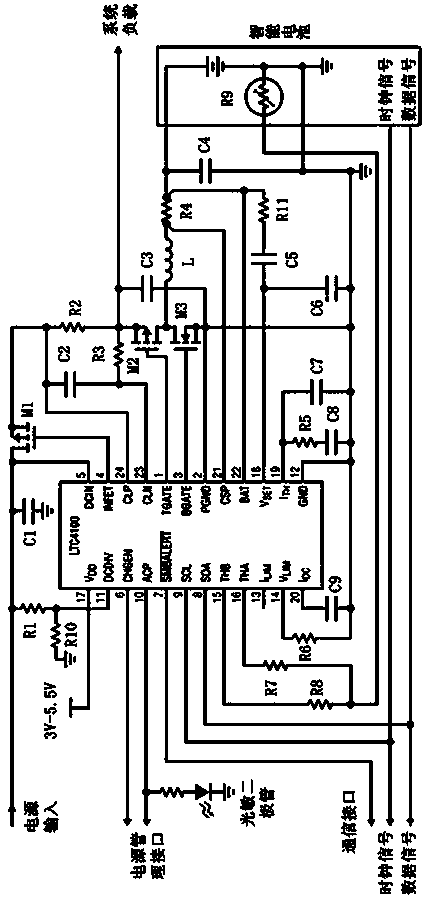

Power supply management system of road test device

ActiveCN106253404AReal-time monitoring status informationElectric powerBattery load switchingElectricityLow noise

The invention discloses a power supply management system of a road test device. The power supply management system comprises a main control module, a power supply charging and discharging management module, a power supply conversion module, a port module, a low-noise antenna power supply and a reserved serial port. The port module comprises a power supply port and an Ethernet port. The output end of the power supply charging and discharging management module is connected with the power supply conversion module and the input end of the main control module. The output end of the main control module is connected with the power supply charging and discharging management module, the Ethernet port, the reserved serial port and the input end of the power supply conversion module. The output end of the power supply conversion module is connected with the main control module, the power supply port and the input end of the low-noise antenna power supply. The power supply management system is capable of providing electricity for a long time for a mobile monitoring vehicle of the road test device, also monitoring state information of other kinds of devices, and carrying out functional processing of supplying electricity and cutting off electricity on the device through a network instruction.

Owner:CHENGDU JIUHUA YUANTONG TECH DEV

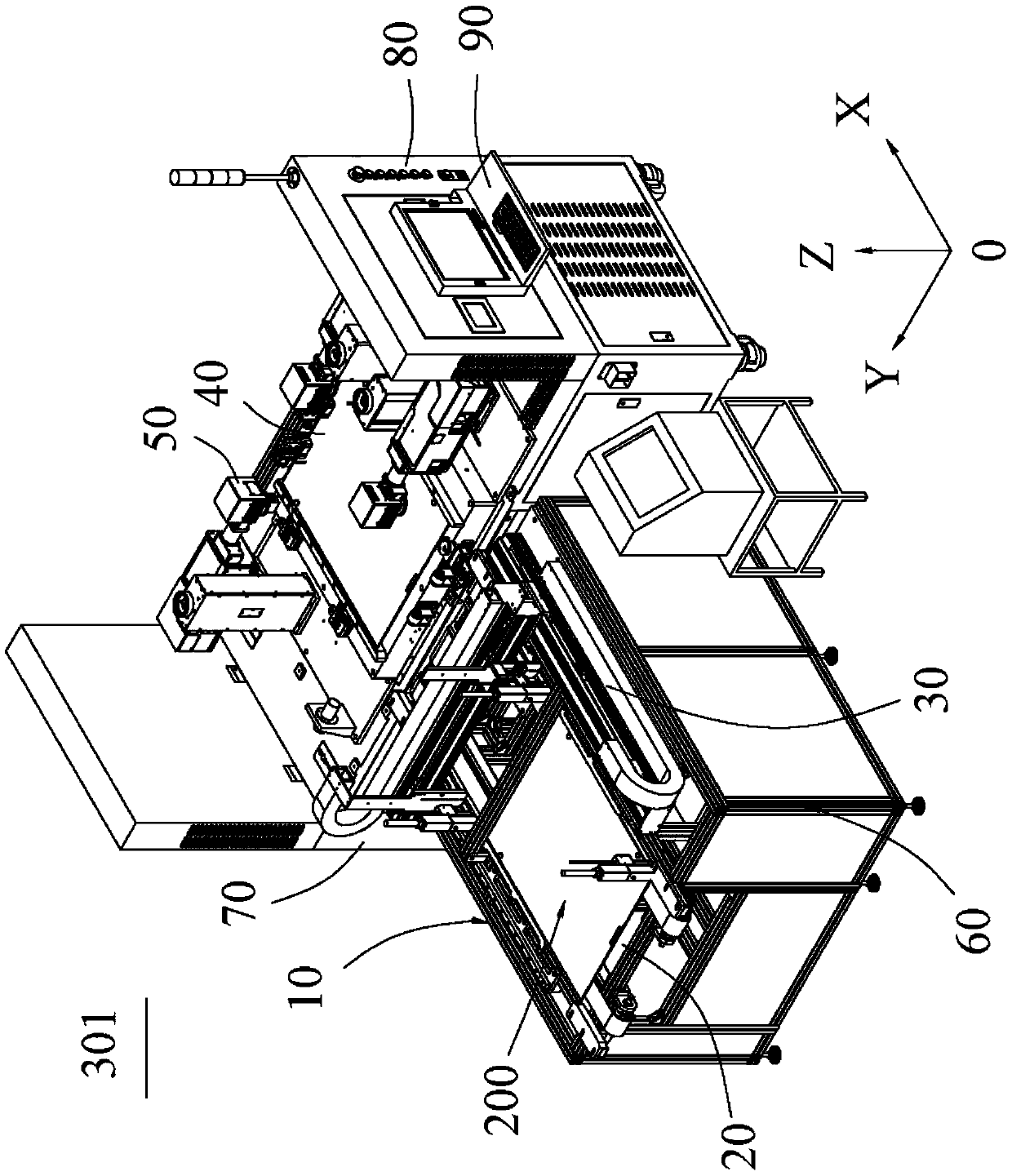

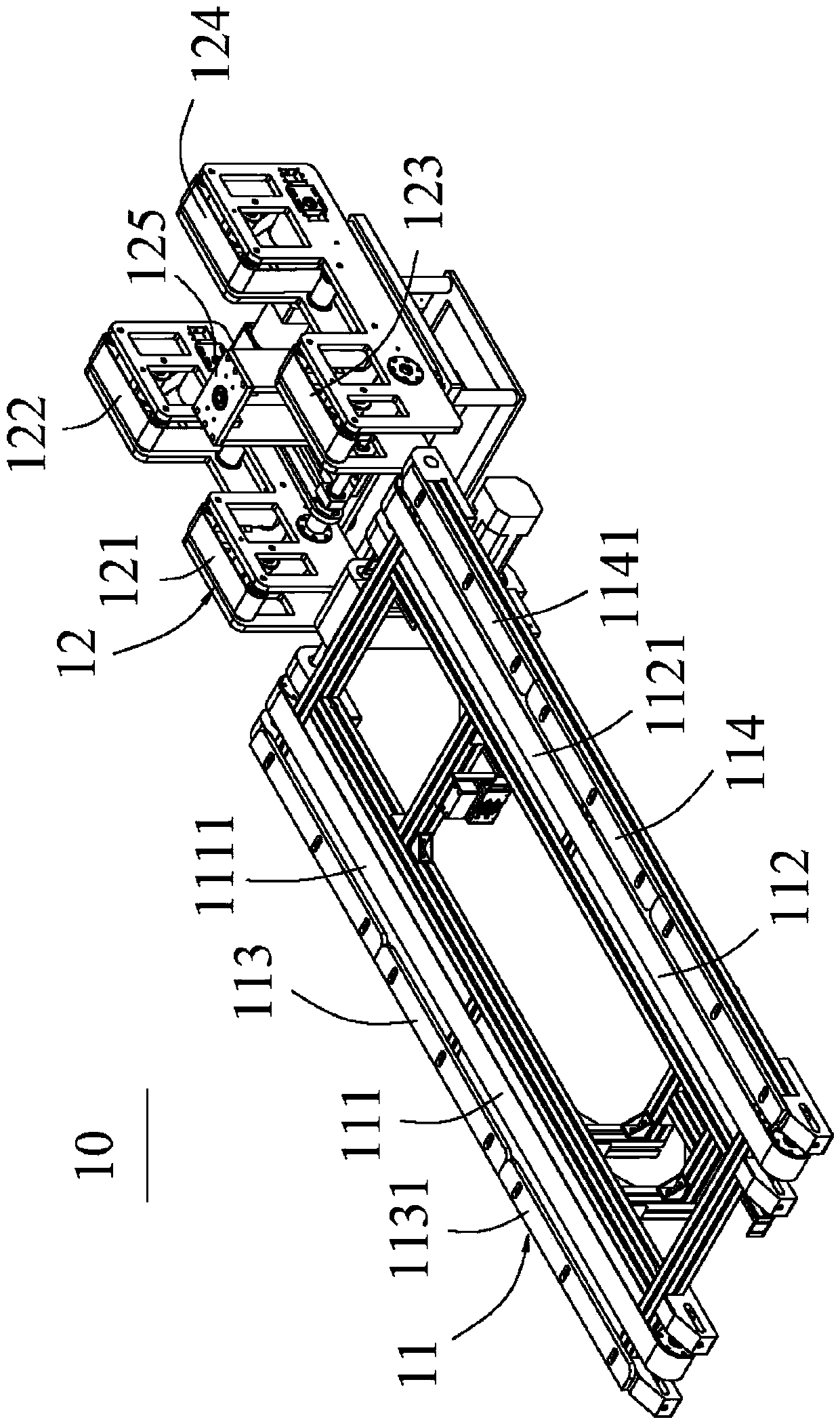

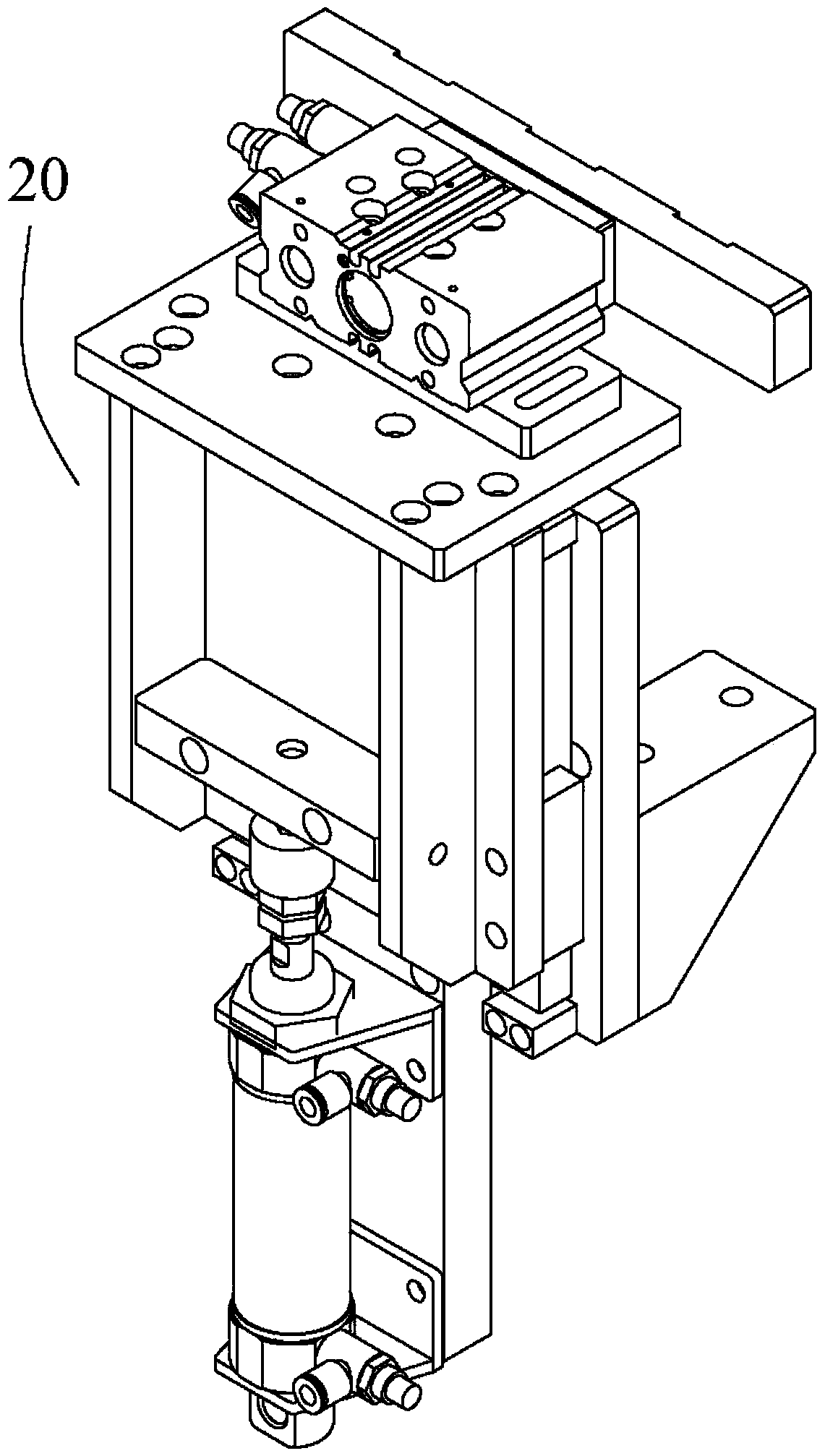

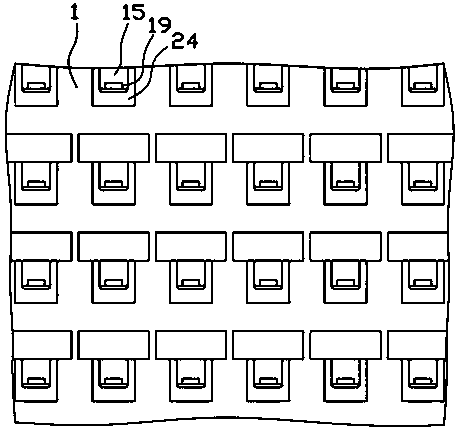

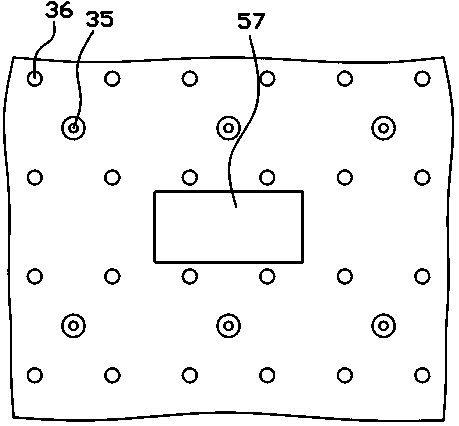

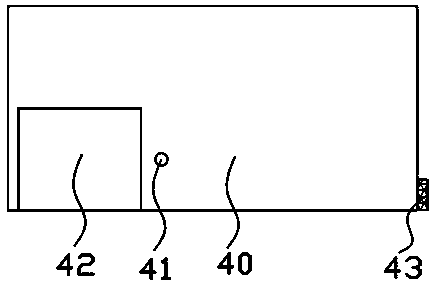

Worktable for automatic ink jetting and laser processing and positioning

ActiveCN105500922AExtend your lifeRealize editingTypewritersOther printing apparatusAssembly lineOutput device

The invention provides a worktable for automatic ink jetting and laser processing and positioning. The worktable is used for jetting a code onto a material and marking the material with a laser, and comprises an automatic conveying assembly line, a two-dimensional automatic ink-jetting platform, and a laser processing system. The automatic conveying assembly line comprises a front-end input device and a rear-end output device. The two-dimensional automatic ink-jetting platform is arranged on the input device of the automatic conveying assembly line and comprises a code-jetting machine positioning and processing platform arranged on the output device of the automatic conveying assembly line and supporting the material to be marked. The laser processing system is used for marking the material on the positioning and processing platform with a laser. The worktable for automatic ink jetting and laser processing and positioning employs the automatic conveying assembly line and a host system controls, by a motion control card, jet printing loci such as the moving speed of a nozzle, the position of the nozzle, the jet printing speed, and jet printing start and stop positions. Parameters can be flexibly configured and modified in order to correspond to products with different specifications. The worktable communicates with host software via a serial port so as to edit and jet print self-defined texts, patterns, and bar codes.

Owner:HANS LASER TECH IND GRP CO LTD

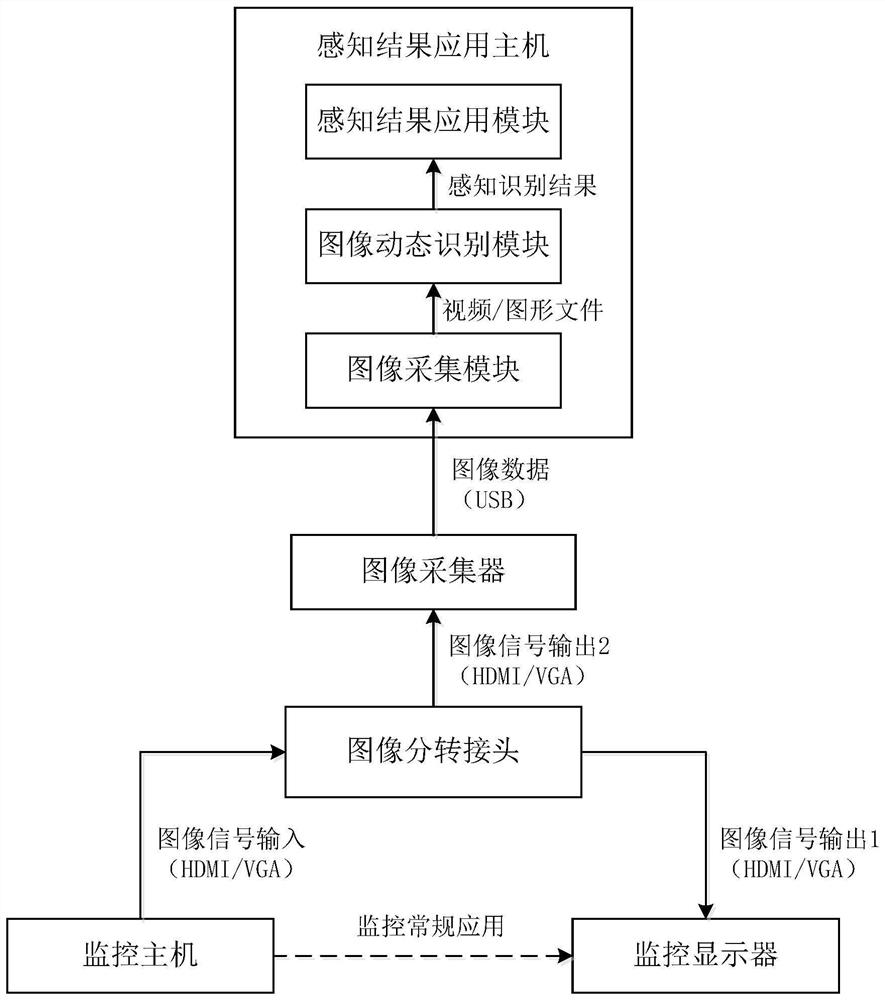

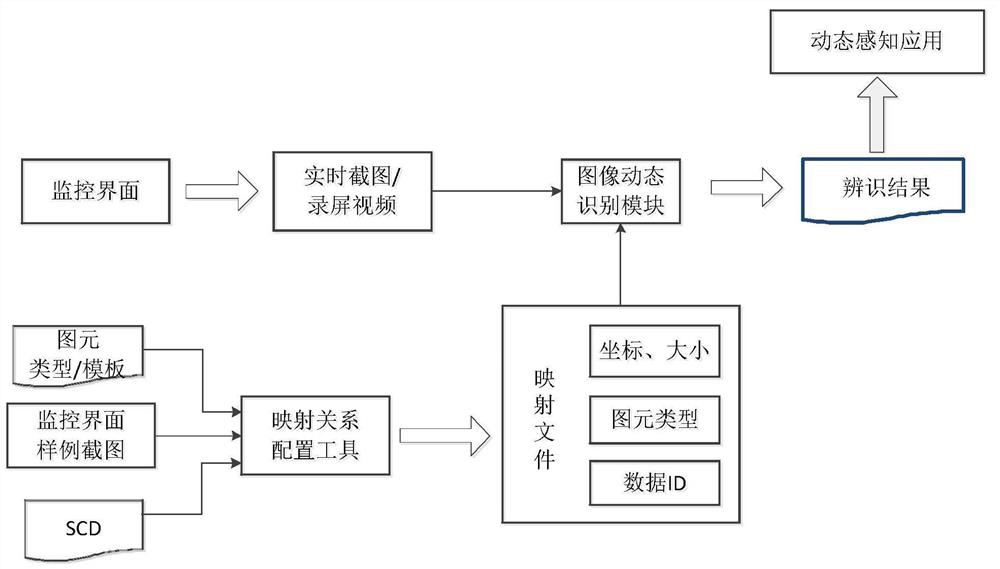

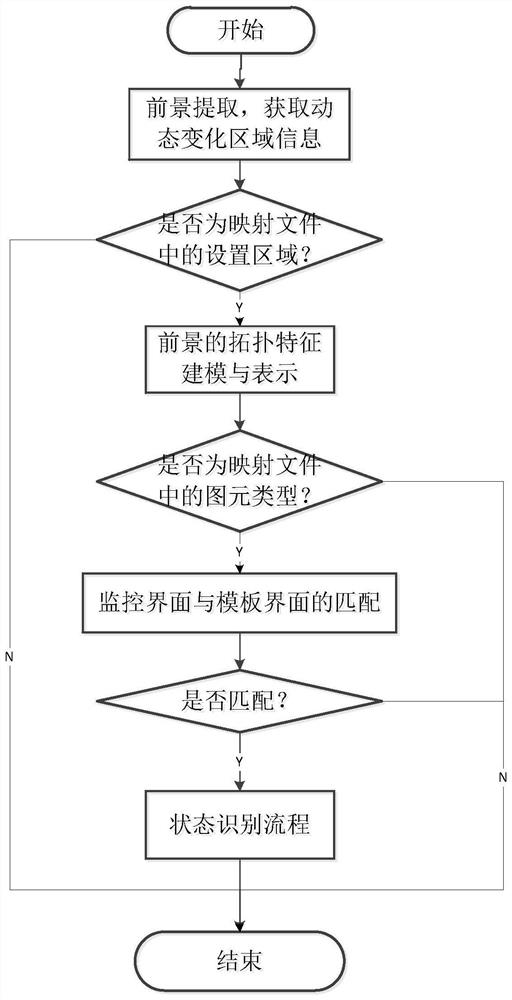

Transformer substation monitoring interface electric power icon dynamic perception recognition system and method

ActiveCN112181549AImprove detection efficiencyDoes not interfere with normal operationData processing applicationsCharacter and pattern recognitionData fileEngineering

The invention discloses a transformer substation monitoring interface power icon dynamic perception recognition system and method. The recognition system comprises a monitoring host, an image adapter,an image collector and a perception result application host which are connected in sequence. The monitoring host is used for collecting equipment change information in a transformer substation and then sending the equipment change information to the image collector in an image signal mode through the image adapter. The image collector converts the received image signal into a video or image datafile in real time, and stores the video or image data file in a management file directory pre-configured by the perception result application host; and the perception result application host identifies the dynamic information of the specific power icon changing with time from the stored video or image data file, and applies the identified dynamic information of the specific power icon changing with time. According to the invention, manual recognition in the prior art is changed into full-automatic recognition by a machine, so that the recognition work efficiency is greatly improved.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

Multifunctional classroom and use method thereof

ActiveCN109723249AImprove teaching efficiencyImprove learning efficiencyHospitalsBuilding constructionsDrive motorHigh definition

The invention relates to a multifunctional classroom. The multifunctional classroom comprises a protective layer and a service terminal, wherein the protective layer is laid on the floor of a classroom and is provided with a lifting passage, a platform splicing groove and an abutting fixing groove, the lifting passage is provided with a first track, a first telescopic motor, a soundproof blockingplate, a blocking groove and a platform fixing groove and is communicated with a sanitary passage, the sanitary passage is communicated with a moving passage, the moving passage is provided with a moving toilet, the first track is connected with a lifting platform through first moving rollers, the lifting platform is provided with a first drive motor, a multi-function seat, a second telescopic motor, a platform fixing plate, a telescopic splicing groove, a telescopic placement groove, a third telescopic motor, a telescopic rotating plate, a fourth telescopic motor and an abutting telescopic plate, the classroom is provided with a high-definition camera, a warning light, a platform and student desks, the service terminal is arranged in a security room, and teachers and students are providedwith a variety of functional services to improve the teaching efficiency of the teachers and improve the learning efficiency of the students.

Owner:太仓市经贸小学

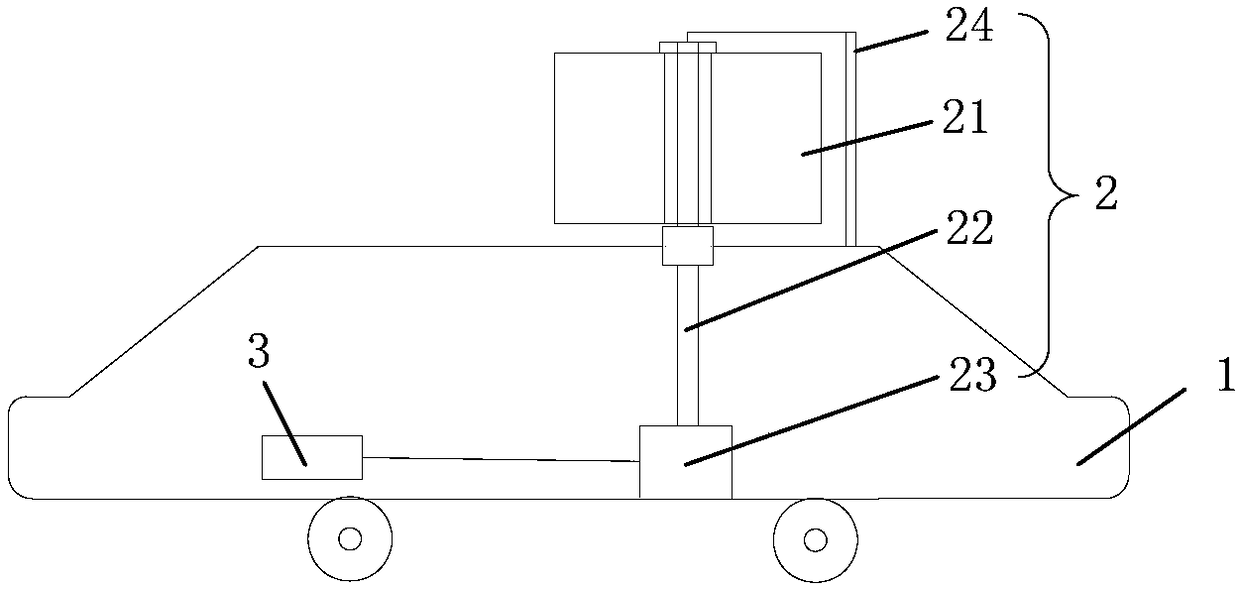

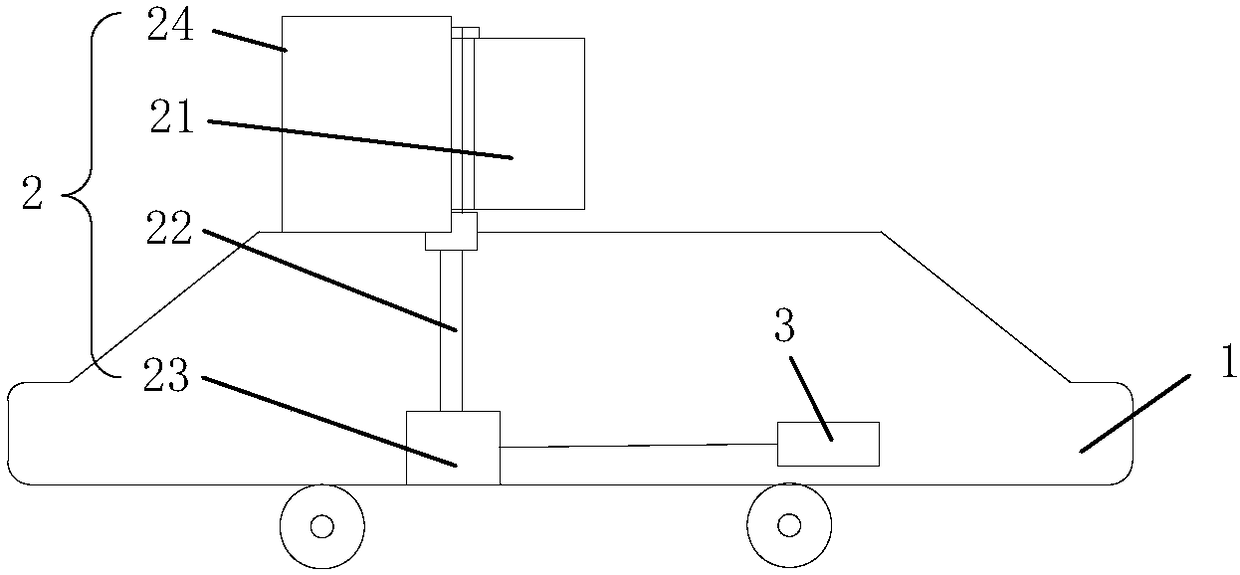

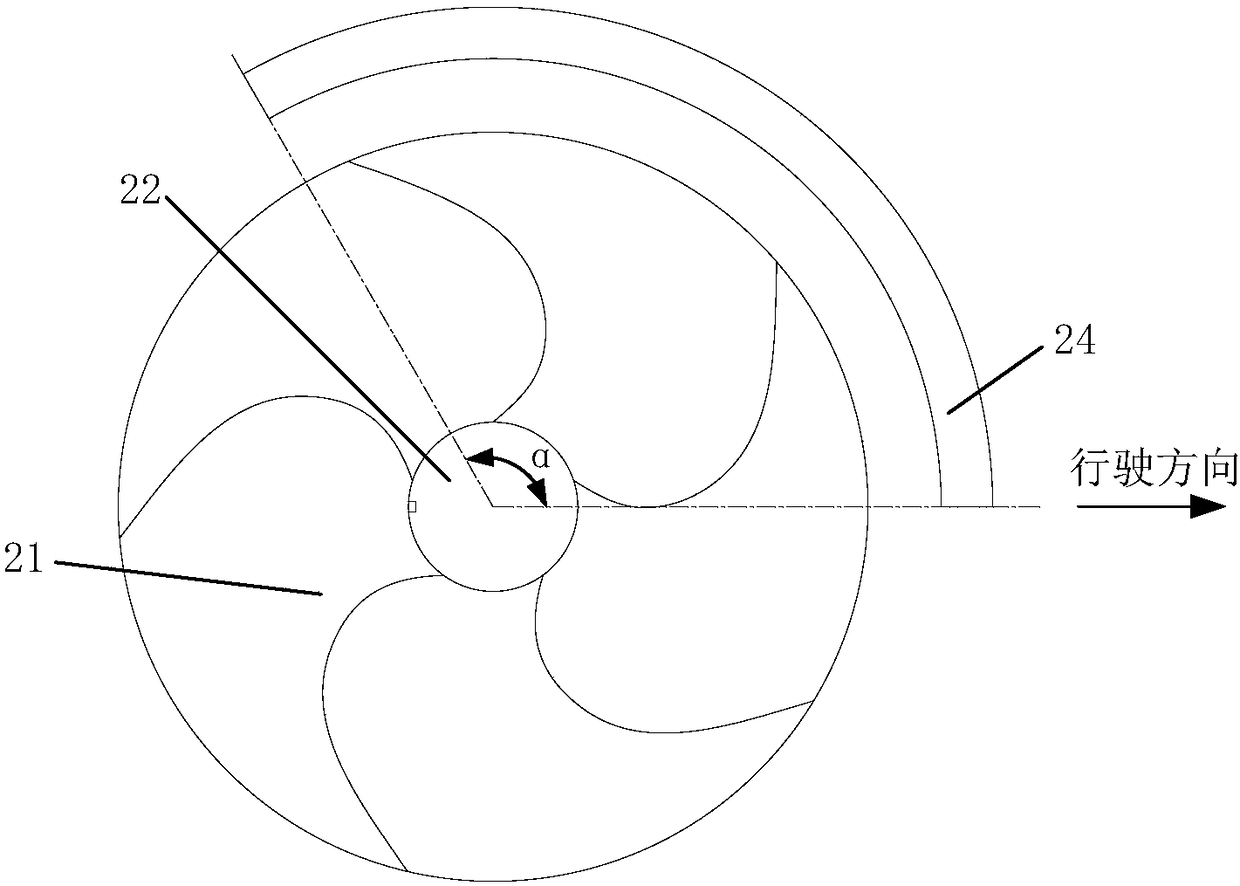

Wind energy battery electric vehicle

PendingCN108177532AMonitor usage in real timeReal-time monitoring of running statusWind energy with electric storageEnergy storageElectricityNew energy

The invention provides a wind energy battery electric vehicle and relates to the technical field of new-energy automobiles. The wind energy battery electric vehicle comprises a vehicle body and an electricity consumption component and further comprises a wind power generation device, an energy storage device and a monitoring device; the wind power generation device is arranged on the vehicle bodyand used for converting wind energy into electric energy; the energy storage device is electrically connected with the wind power generation device, used for storing the electric energy converted by the wind power generation device, electrically connected with the electricity consumption component and used for supplying a power source to the wind energy battery electric vehicle; and the monitoringdevice is electrically connected with the energy storage device and used for monitoring state information of the energy storage device in real time. The wind energy generated in the traveling processof the wind energy battery electric vehicle is converted into the electric energy, efficient utilization of energy is achieved, the vehicle has important significance in environment protection, the energy storage device can be effectively protected as well, and the service life of the energy storage device is prolonged.

Owner:任金良

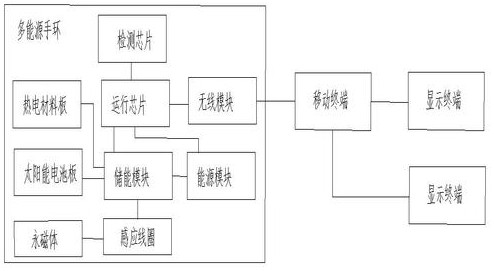

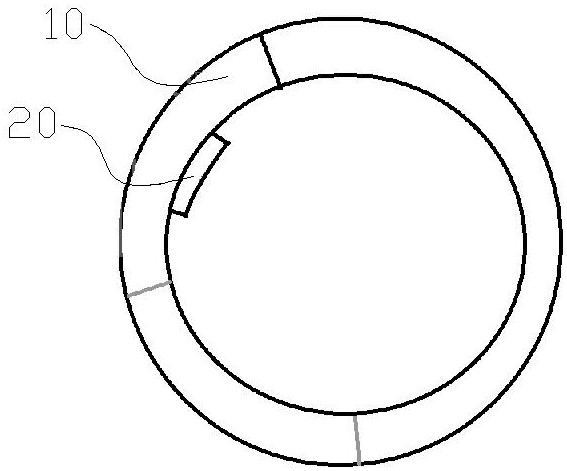

Multi-energy bracelet monitoring system

InactiveCN112716470AReal-time monitoring status informationImprove battery lifeBatteries circuit arrangementsBraceletsThermoelectric materialsMonitoring system

The invention discloses a multi-energy wristband monitoring system, which comprises a multi-energy wristband, a mobile terminal and at least one display terminal, the multi-energy bracelet comprises an annular main body, a detection chip arranged on the inner side of the annular main body, a solar cell panel and a thermoelectric material plate arranged on the outer side of the annular main body, an operation chip, an energy storage module, an energy module and a wireless module arranged in the annular main body. The solar cell panel and the thermoelectric material plate are respectively connected with the energy storage module; the energy storage module, the energy module, the operation chip, the detection chip and the wireless module are connected with one another; the wireless module is in wireless connection with the mobile terminal; and the mobile terminal is wirelessly connected with the display terminal. The electric energy can be automatically supplied in the using process, and the cruising ability and reliability of the wristband are improved through supply of various energy sources.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

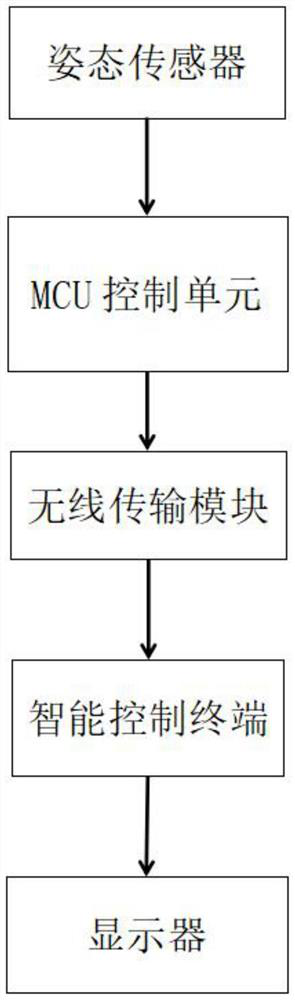

On-line monitoring system of high-voltage isolation switch

InactiveCN113218357AReduce the impactReal-time monitoring status informationMeasurement devicesTransmission systemsWireless transmissionControl cell

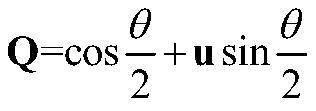

An on-line monitoring system of a high-voltage isolation switch comprises an on-line monitoring terminal, an intelligent control terminal and a display. The on-line monitoring terminal comprises an MCU control unit, an attitude sensor and a wireless transmission module, the three-axis turntable, the attitude sensor and the wireless transmission module are connected with the MCU control unit, and the intelligent control terminal is connected with the display; and the attitude sensor collects disconnecting switch data and transmits the data to the MCU, the MCU processes the data and transmits the data to the wireless transmission module, the wireless transmission module sends the data to the intelligent control terminal, the intelligent control terminal receives the data sent by the wireless transmission module, and the intelligent control terminal transmits the data to the display. Data of the disconnecting switch are collected in real time through the attitude sensor, the rotation angle and the change condition of the disconnecting switch are calculated, so that whether the disconnecting switch is switched on and switched off in place or not is judged, monitoring data are sent in a wireless transmission mode, and state information of the disconnecting switch can be monitored in real time.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +1

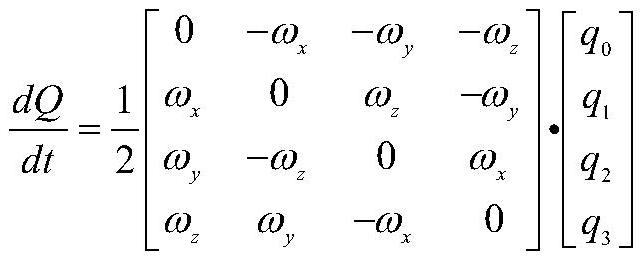

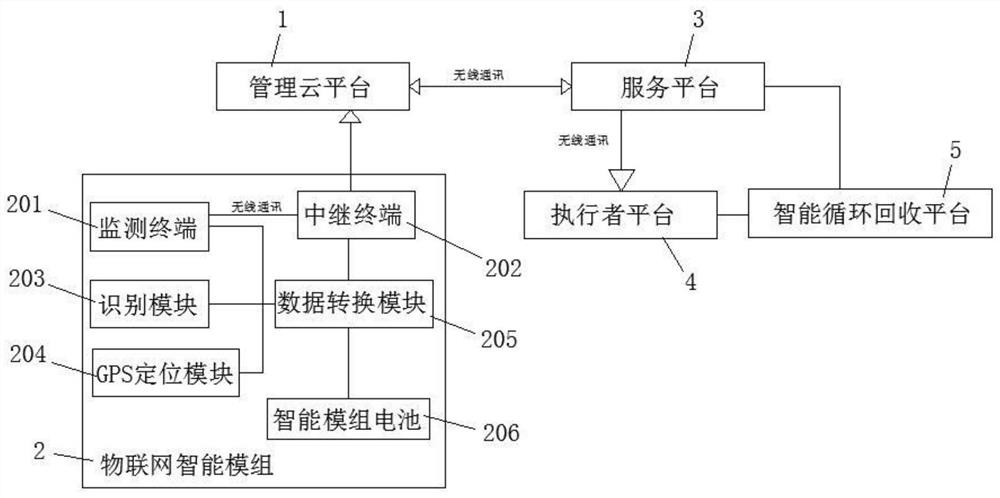

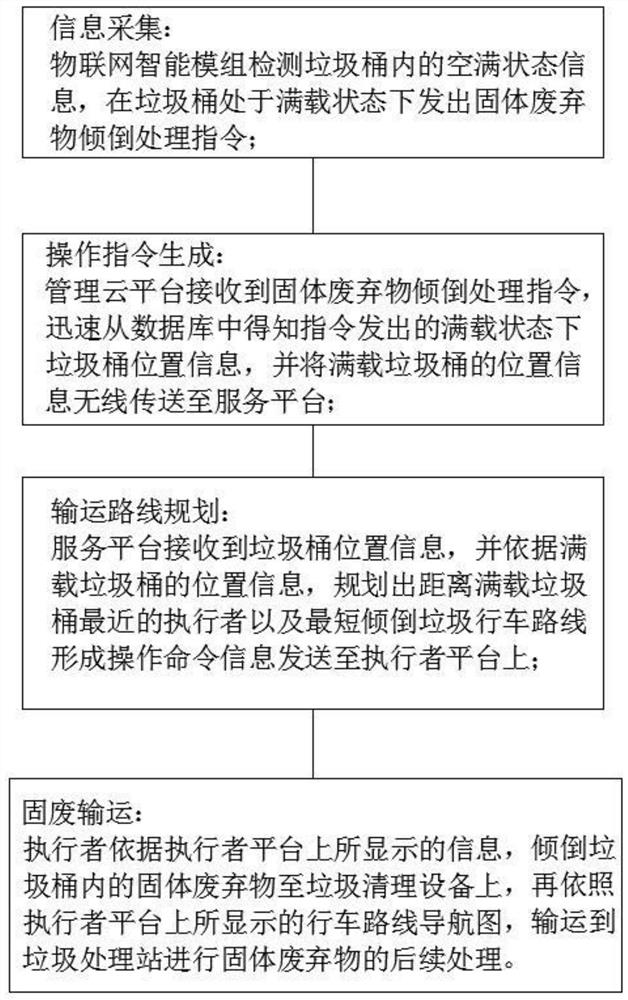

Solid waste transportation system and transportation method based on Internet of Things

PendingCN113256215AReal-time monitoring status informationRealize intelligent automatic transportationCharacter and pattern recognitionSatellite radio beaconingInternet of ThingsData information

The invention discloses a solid waste transportation system based on the Internet of Things. The system comprises: a management cloud platform; the Internet of Things intelligent module that is used for collecting data information of solid waste in the garbage can so as to judge state information of the garbage can; the service platform that is used for being remotely connected with the management cloud platform and generating operation command information when the garbage can state information is in a full-load state; and the executor platform that is used for receiving the operation command information sent by the service platform, and an executor carries out solid waste transportation work according to the given operation command information. The state information of the solid waste in the garbage can can be monitored in real time, the transportation route can be autonomously planned, the transportation execution personnel can be designated and prompted to carry out solid waste transportation work, intelligent and automatic transportation of the solid waste is achieved, the transportation efficiency of the solid waste is improved, and the transportation cost of the solid waste is reduced.

Owner:SHENZHEN LUHUAN REGENERATION RESOURCE DEV CO LTD

A new energy vehicle intelligent guided charging system

InactiveCN105620303BScientific and effective managementImprove management efficiencyCharging stationsMobile unit charging stationsNew energyComputer terminal

The invention discloses an intelligent guide charging system of a new energy vehicle. The system comprises a charging pile group, a sub management system, a remote management center and a user client terminal; the charging pile group is connected with the sub management system through a CAN bus; the sub management system is provided with a LPE-CPE terminal, and is connected to a TD-LTE network through the LPE-CPE terminal; the remote management center performs data exchange with the sub management system and the user client terminal through the TD-LTE network; the charging pile group includes multiple independent charging piles; the independent charging piles are connected with the CAN bus, and are provided with unique MAC codes; the positions of the independent charging piles are fixed; the position information of the independent charging piles is recorded in the sub management system and the remote management system; the sub management system acquires use states of the independent charging piles in real time, and transfers the information to the remote management center; the user client terminal can obtain the use states and the position information of the independent charging piles at any time; and the user client terminal can guide users to reach the selected positions of the independent charging piles.

Owner:JIANGSU GUOAI ELECTRIC CO LTD

Intelligent monitoring and dynamic fault diagnosis system for underwater Christmas tree

ActiveCN105634819BReal-time monitoring status informationImprove securityNon-electrical signal transmission systemsData switching networksSonarData acquisition

The invention belongs to the field of petroleum engineering and particularly relates to an intelligent monitoring and dynamic fault diagnosis system for a subsea tree. The intelligent monitoring and dynamic fault diagnosis system for the subsea tree comprises signal reception and fault diagnosis sub-systems and data acquisition and sonar signal emission sub-systems, wherein the signal reception and fault diagnosis sub-systems are located in a control room on a drilling platform, and the data acquisition and sonar signal emission sub-systems are located in undersea control modules; one data acquisition and sonar signal emission sub-system is arranged in each undersea control module; and data transmission between the signal reception and fault diagnosis sub-systems and data acquisition and the sonar signal emission sub-systems is carried out through sonar. According to the intelligent monitoring and dynamic fault diagnosis system for the subsea tree, the status information of multiple undersea tree systems can be monitored in real time and be respectively emitted to an offshore oil platform through sonar signals to carry out comprehensive diagnostic analysis, so that the safety for marine petroleum exploitation is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

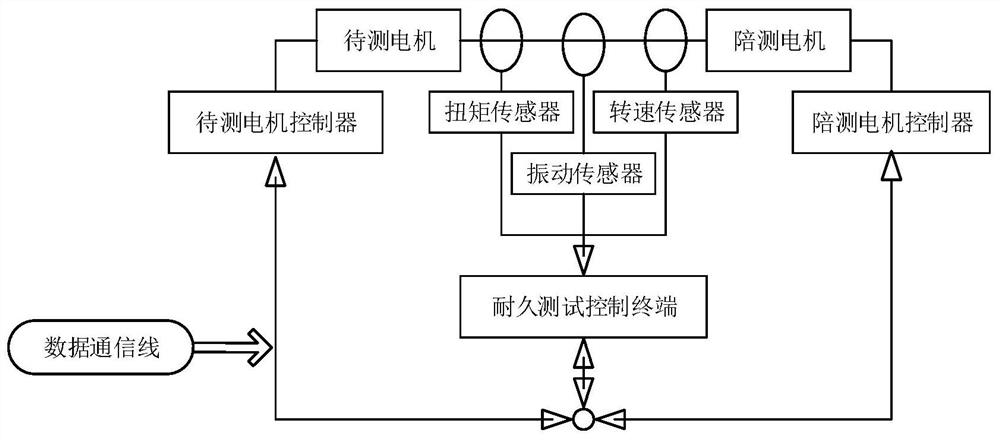

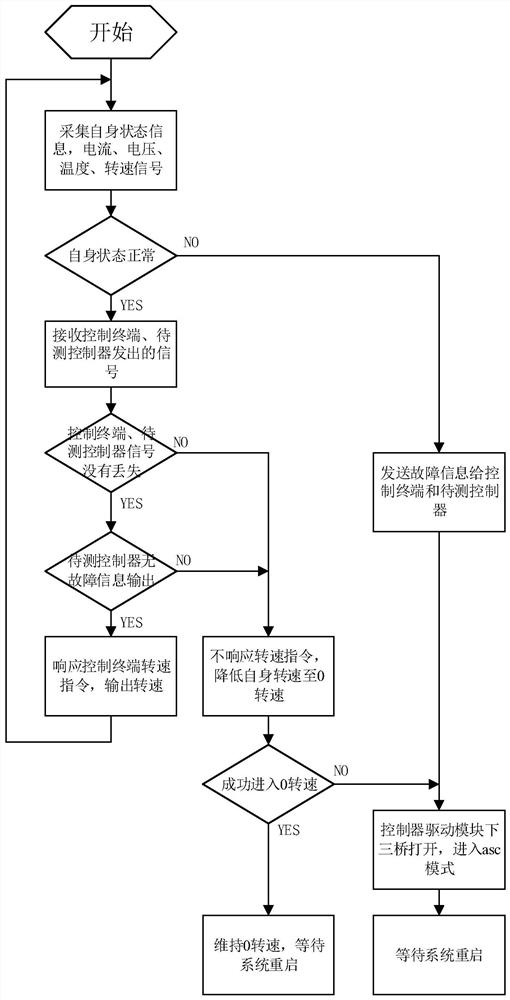

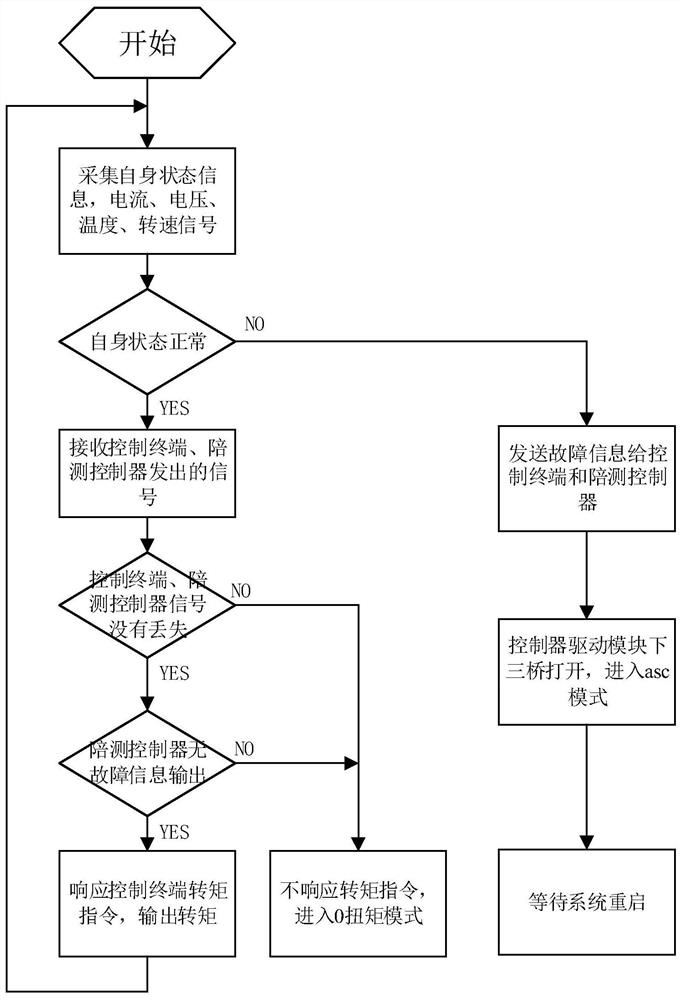

A motor-to-drag durability test system and its safety protection method

ActiveCN110596587BReal-time monitoring status informationSimple structureEmergency protective circuit arrangementsDynamo-electric machine testingControl engineeringElectric machinery

The invention discloses a motor-to-drag durability test system and a safety protection method thereof, comprising a three-phase AC motor to be tested, a motor controller to be tested, a three-phase AC motor to be tested, a motor controller to be tested, a durability test control terminal, Torque sensor, speed sensor, vibration sensor; the motor controller to be tested is used to control the output torque of the motor to be tested, the motor controller to be tested is used to control the output speed of the motor to be tested, the motor controller to be tested, the motor controller to be tested and the The three nodes of the durability test control terminal are connected to the same communication network; the safety protection method of the motor-to-drag durability test system includes the protection control of the accompanying test terminal, the protection control of the terminal to be tested, and the protection control of the durability test control terminal. In the present invention, three nodes are connected to the same communication network, so that any node can monitor the state information of the other two nodes in real time, thus ensuring that the other two nodes can quickly enter into abnormal protection when any node is abnormal.

Owner:HEFEI JUYI POWER SYST CO LTD

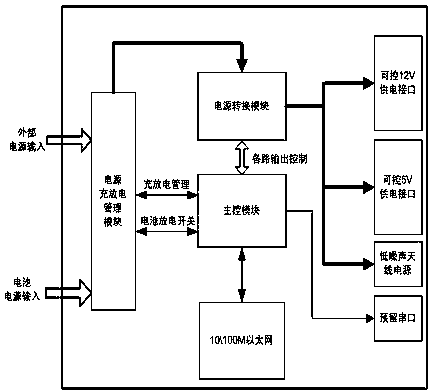

A Power Management System for Drive Test Equipment

ActiveCN106253404BReal-time monitoring status informationElectric powerBattery load switchingElectricityLow noise

The invention discloses a power supply management system of a road test device. The power supply management system comprises a main control module, a power supply charging and discharging management module, a power supply conversion module, a port module, a low-noise antenna power supply and a reserved serial port. The port module comprises a power supply port and an Ethernet port. The output end of the power supply charging and discharging management module is connected with the power supply conversion module and the input end of the main control module. The output end of the main control module is connected with the power supply charging and discharging management module, the Ethernet port, the reserved serial port and the input end of the power supply conversion module. The output end of the power supply conversion module is connected with the main control module, the power supply port and the input end of the low-noise antenna power supply. The power supply management system is capable of providing electricity for a long time for a mobile monitoring vehicle of the road test device, also monitoring state information of other kinds of devices, and carrying out functional processing of supplying electricity and cutting off electricity on the device through a network instruction.

Owner:CHENGDU JIUHUA YUANTONG TECH DEV

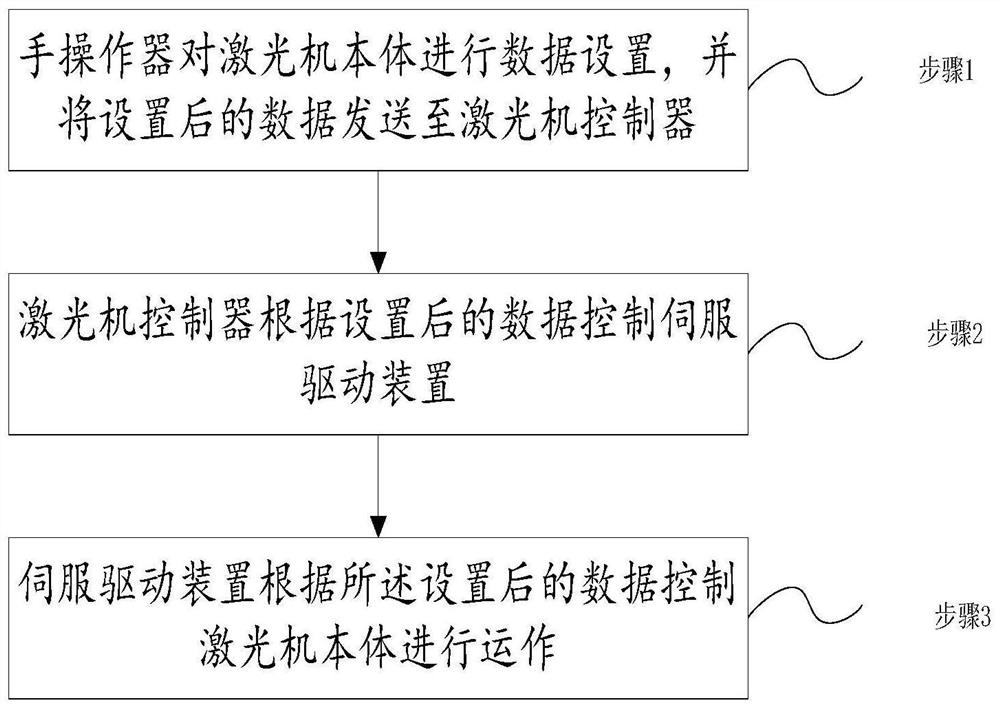

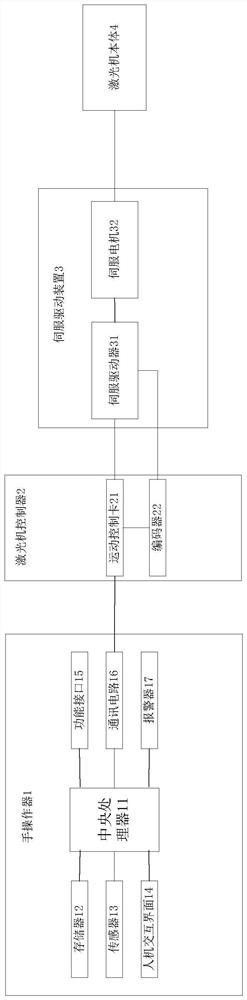

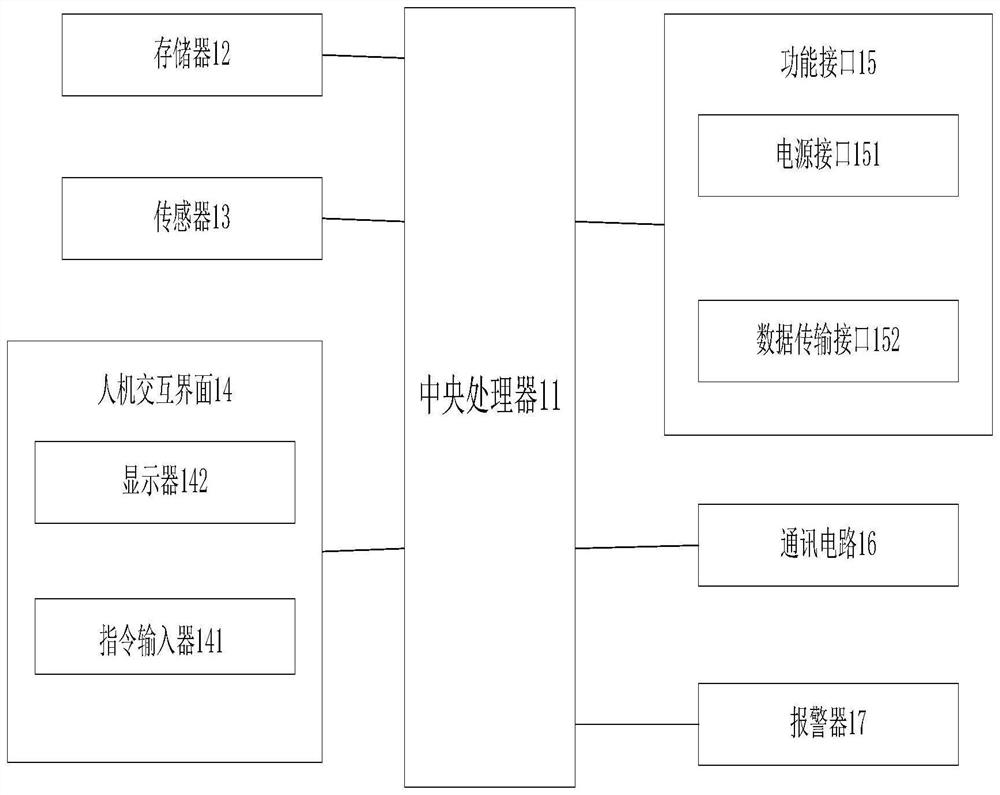

Laser machine control method and system

InactiveCN112255972ARich human-computer interaction meansRealize the control functionNumerical controlData controlMachine control

The invention relates to the field of mechanical engineering control, in particular to a laser machine control method and system. The method comprises the steps that 1, a manual operator carries out the data setting of a laser machine body, and transmits the set data to a laser machine controller; 2, the laser machine controller controls a servo driving device according to the set data; and 3, theservo driving device controls the laser machine body to operate according to the set data. By means of the method, rich man-machine interaction means can be provided, complex track planning can be rapidly completed, teaching programming does not need to be conducted in advance, the application range is wider, and the method can be widely popularized.

Owner:GUANGZHOU INST OF RAILWAY TECH

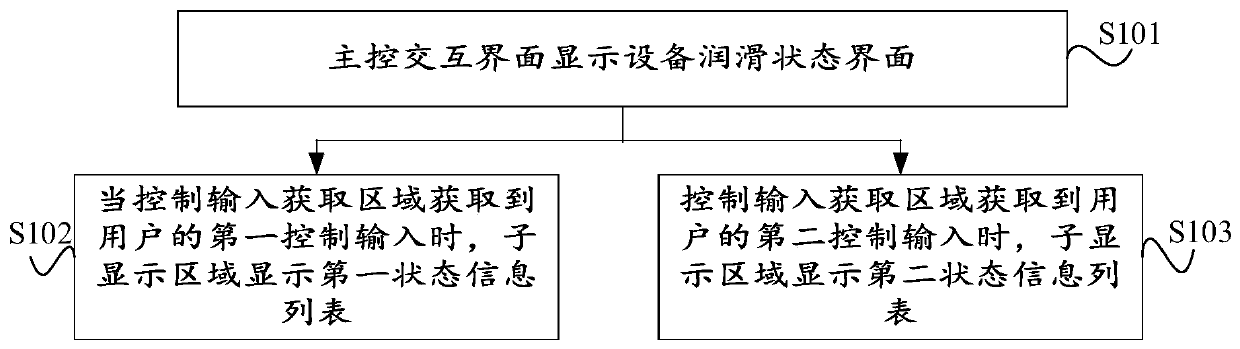

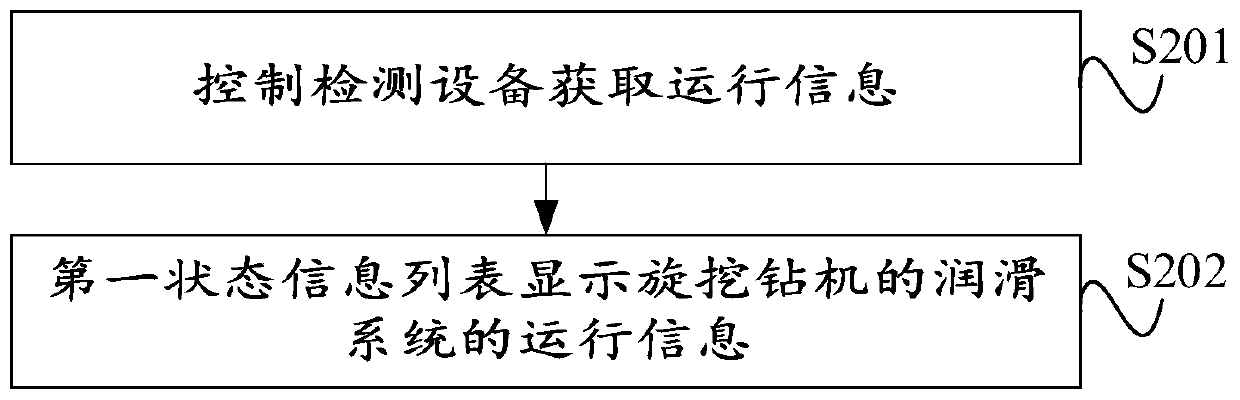

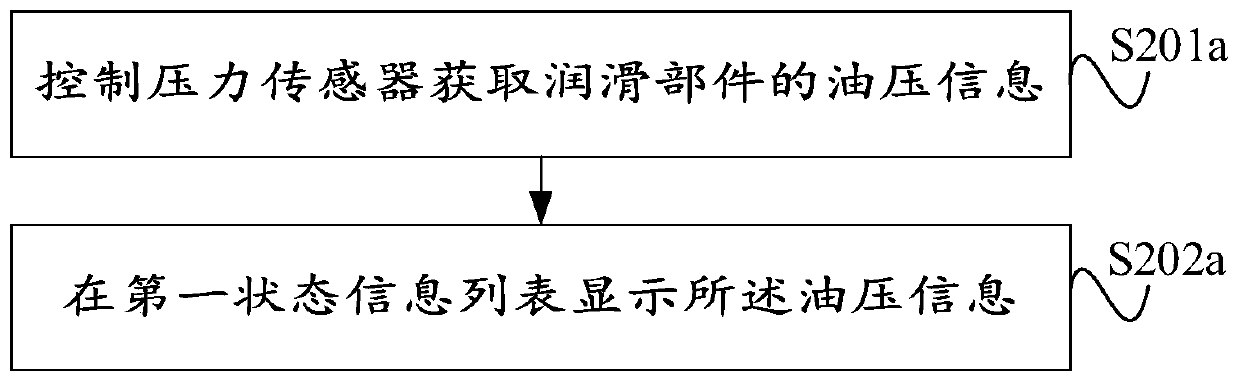

Interactive interface display method and device for rotary drilling rig lubricating system

InactiveCN109782979AEasy to controlReal-time monitoring status informationHardware monitoringInput/output processes for data processingUser inputEngineering

The invention provides an interactive interface display method and device for a rotary drilling rig lubricating system, and relates to the field of interface display. The method is applied to a main control operation table, the main control operation table is arranged in a cab of the rotary drilling rig, the main control operation table is provided with a main control interaction interface, the main control interaction interface displays an equipment lubrication state interface, and the equipment lubrication state interface comprises a control input obtaining area and a sub-display area; whenthe control input acquisition area acquires a first control input of a user, the sub-display area displays a first state information list, and the first state information list displays operation information of a lubricating part of the rotary drilling rig; and when the control input acquisition area acquires a second control input of the user, the sub-display area displays a second state information list, and the second state information list is used for the user to input a control instruction. And a user can conveniently control and monitor the lubricating state interface of the equipment inthe cab in real time.

Owner:BEIJING SANY INTELLIGENT MFG TECH CO LTD

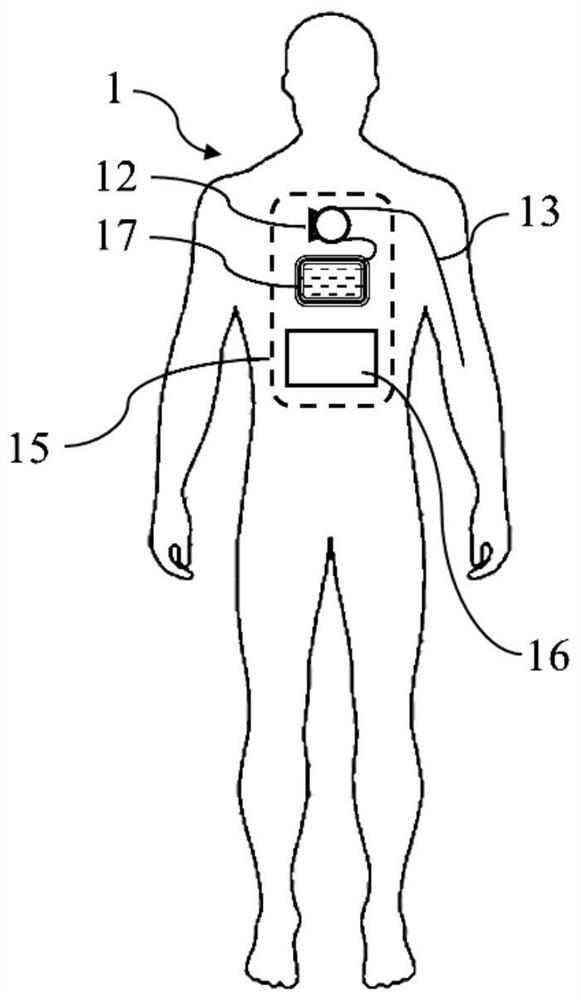

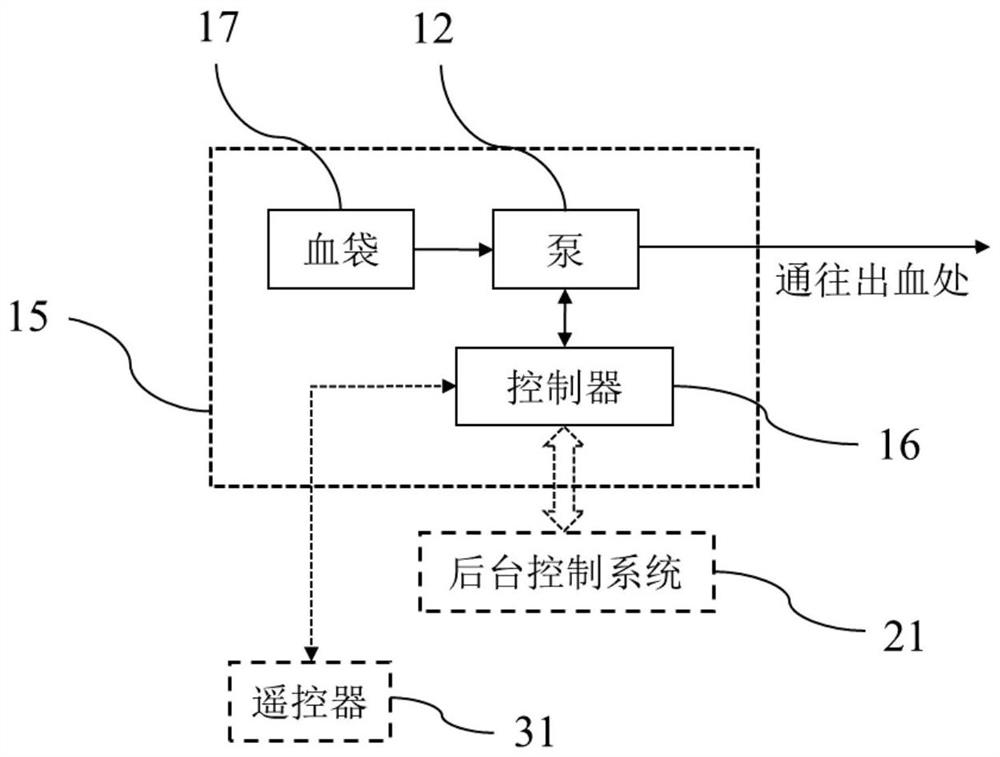

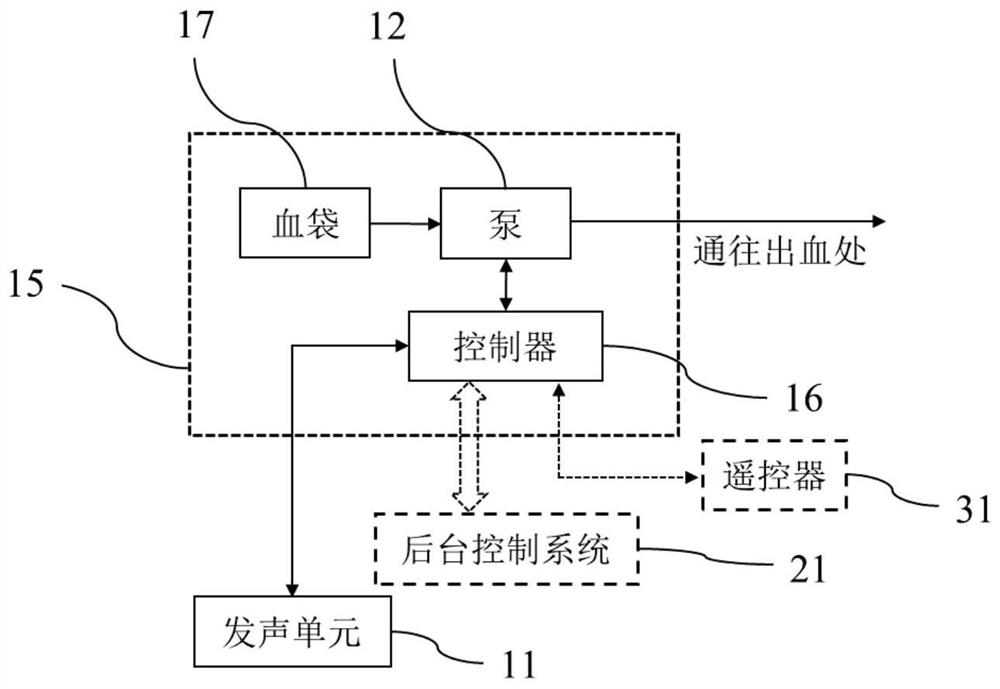

Hemostasis training system and simulated human body model for battlefield rescue training

InactiveCN112201130AHuman body is highly realisticMeet the needs of compression hemostasis trainingEducational modelsHuman bodyPhysical medicine and rehabilitation

The invention provides a hemostasis training simulation system. The hemostasis training simulation system comprises a blood bag, a blood transfusion tube, a pump and a controller, wherein the blood bag is used for containing red liquid, the blood bag is connected to the input end of the pump through the blood transfusion tube and leads to the outside through the blood transfusion tube via the output end of the pump so as to output the red liquid to the outside through the pump, and the controller receives an external instruction and controls and adjusts starting and stopping of the pump and the rotating speed of the pump according to the instruction, so that the speed of outputting the red liquid outwards through the blood transfusion tube is controlled. The invention further provides a simulated human body model for battlefield rescue training provided with the hemostasis training simulation system and a control method of the simulated human body model. The hemostasis training simulation system and the simulated human body model are high in human body trueness, can meet field training requirements, and can meet tourniquet pressurization hemostasis training requirements.

Owner:TONGFANG INDAL

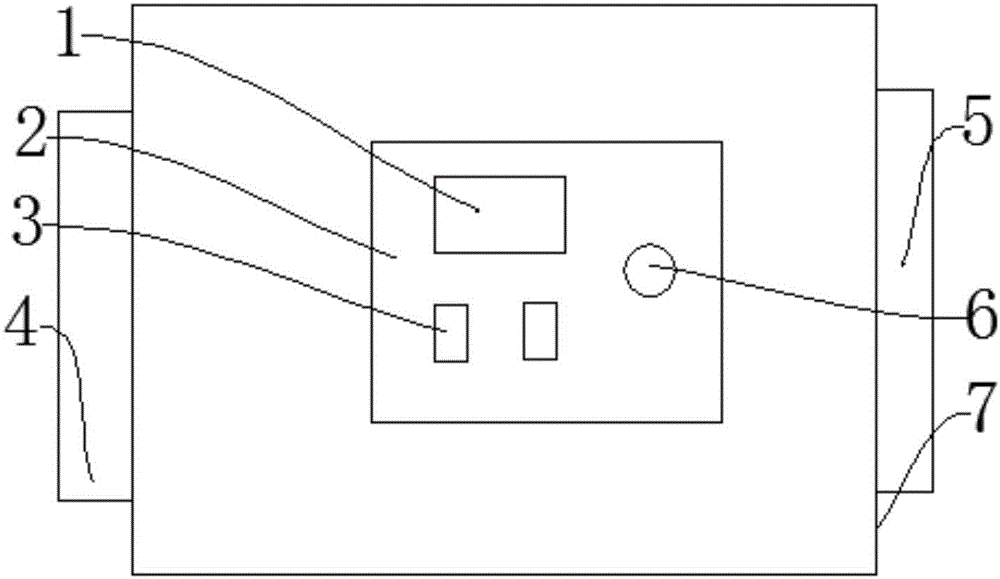

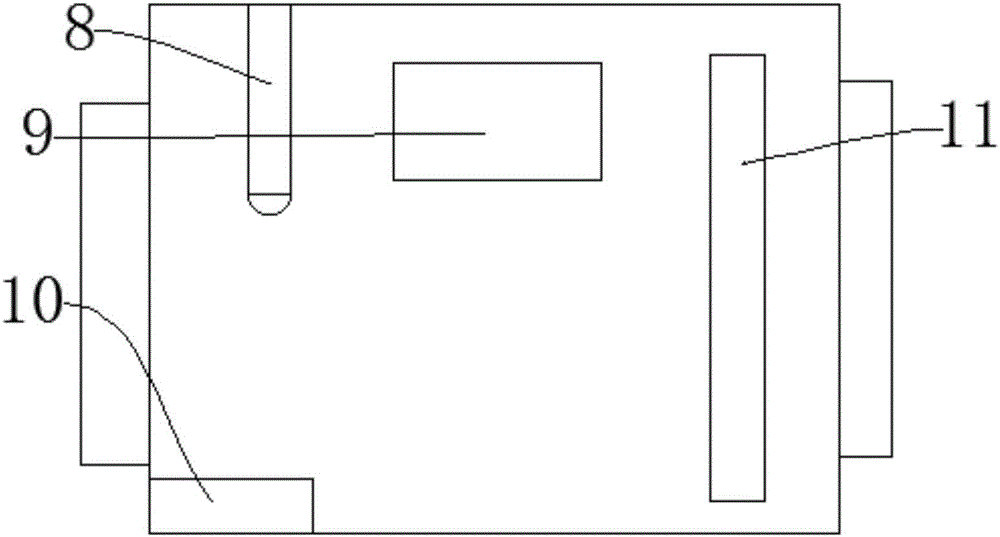

Output device for distributed information processing system

InactiveCN106708683AReal-time monitoring status informationFound in timeDetecting faulty hardware by power-on testHardware monitoringDistributed information processingOutput device

The invention discloses an output device for distributed information processing system. The output device comprises a machine body, a battery, a junction box and a control button. An input information joint is placed on one side face of the machine body, while an output information joint is placed on the other side face of machine body. A control panel is arranged in the surface of the machine body, a display screen is arranged on the control panel, the control button is mounted beside the display screen, a power switch is mounted beside the control button. An infrared camera is installed above the inside wall of machine body, a control host is installed beside the infrared camera. The junction box is disposed beside the control host, the battery is disposed on the underside of the machine body. The output device has the advantages that the component status information inside the device is monitored in real time, and the fault positions are found in time without disassembling the machine to check when faults occurred by the display screen.

Owner:南京傲速致力信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com