Automatic detection system and method for new energy AGC or AVC control system

An automatic detection and control system technology, applied in the general control system, control/adjustment system, test/monitoring control system, etc., can solve the problems of difficulty in cooperating between transmission and devices, small number of simulation devices, and long construction period. Achieve the effect of shortening the test time, high actual value and saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

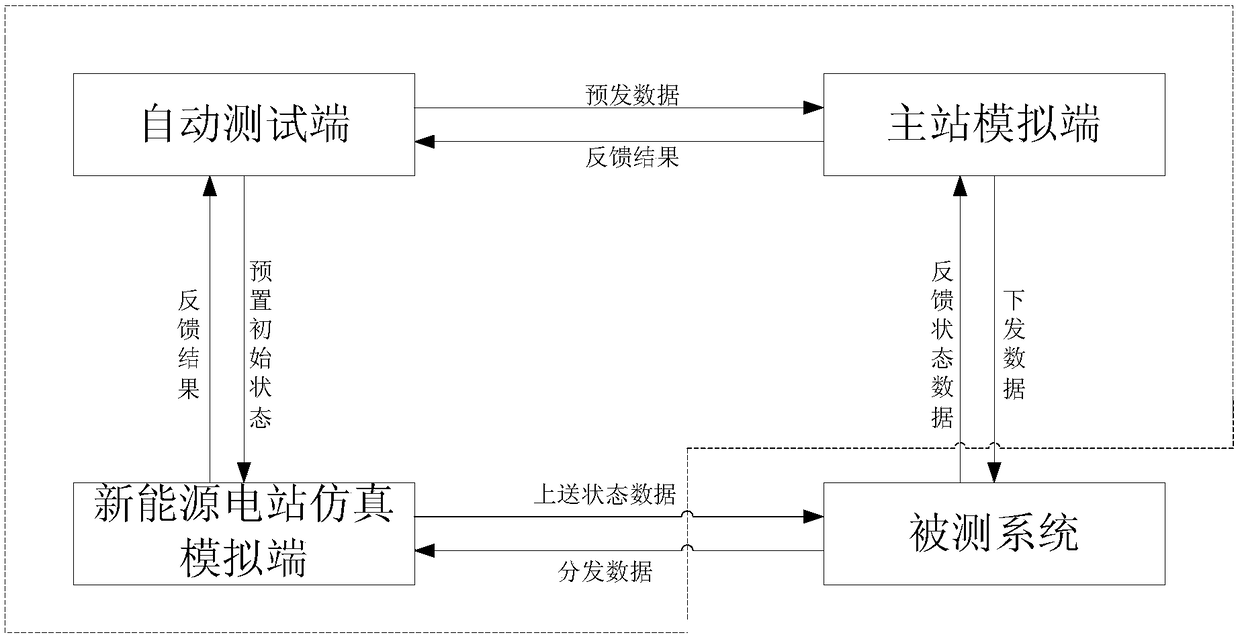

[0053] Such as figure 1 As shown, an automatic detection system for a new energy AGC or AVC control system, including an automatic test terminal, a master station simulation terminal, and a new energy power station simulation simulation terminal;

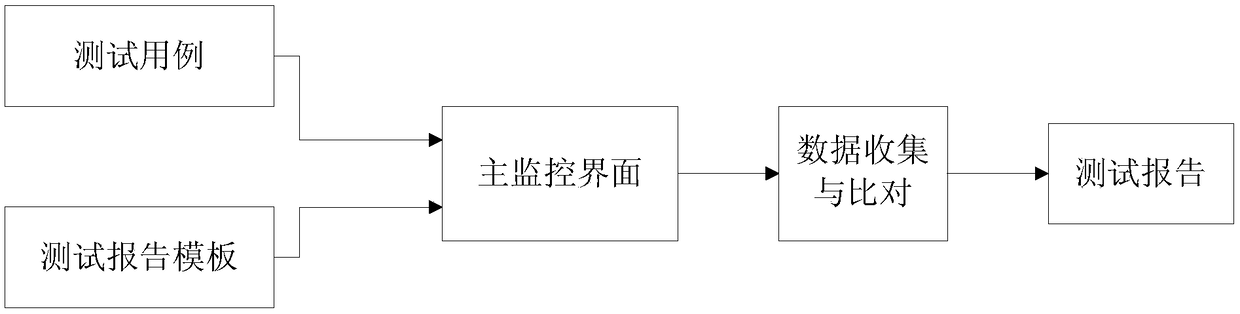

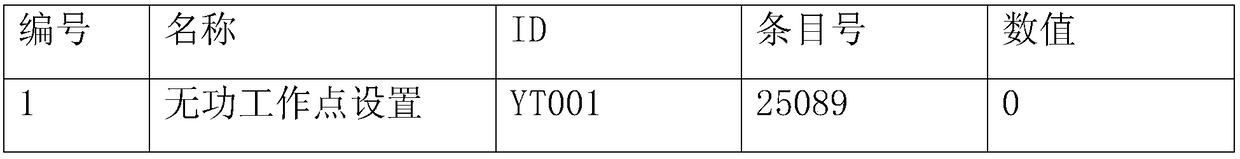

[0054] The automatic test terminal is used to create test cases, compare data processing, generate test reports, send test cases to the simulation terminal of the master station, and send preset initial state values of equipment and remote adjustment and remote control to the simulation terminal of the new energy power station Target parameters and target values that need to be detected, such as bus voltage, active power, etc.;

[0055] The simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com