Worktable for automatic ink jetting and laser processing and positioning

A laser processing and workbench technology, which is applied to printing devices, printing, typewriters, etc., can solve the problems of cracks, cracks, and inability to machine the tempered glass surface, and achieve the effects of life extension, transformation cost savings, and reduction of transformation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

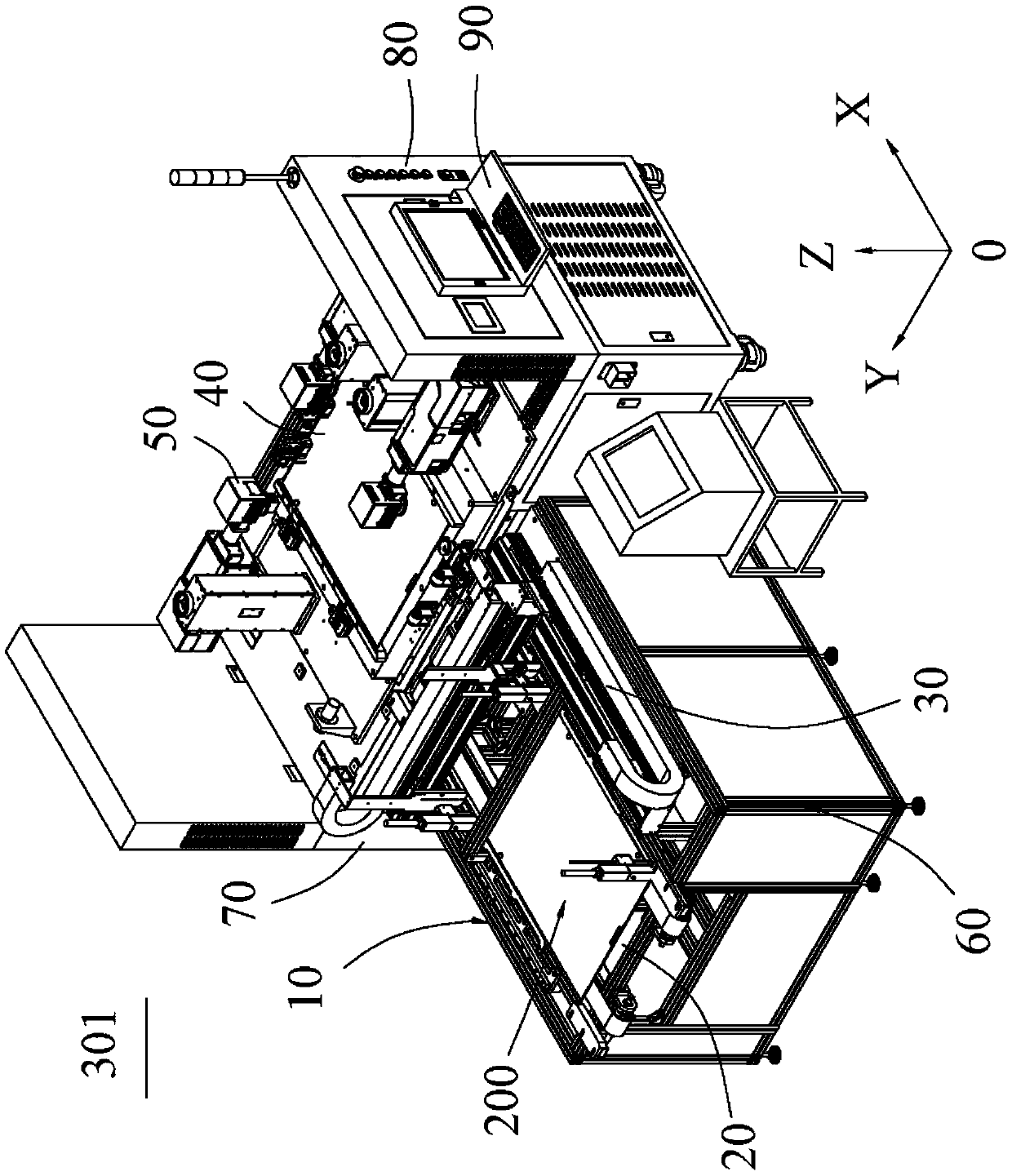

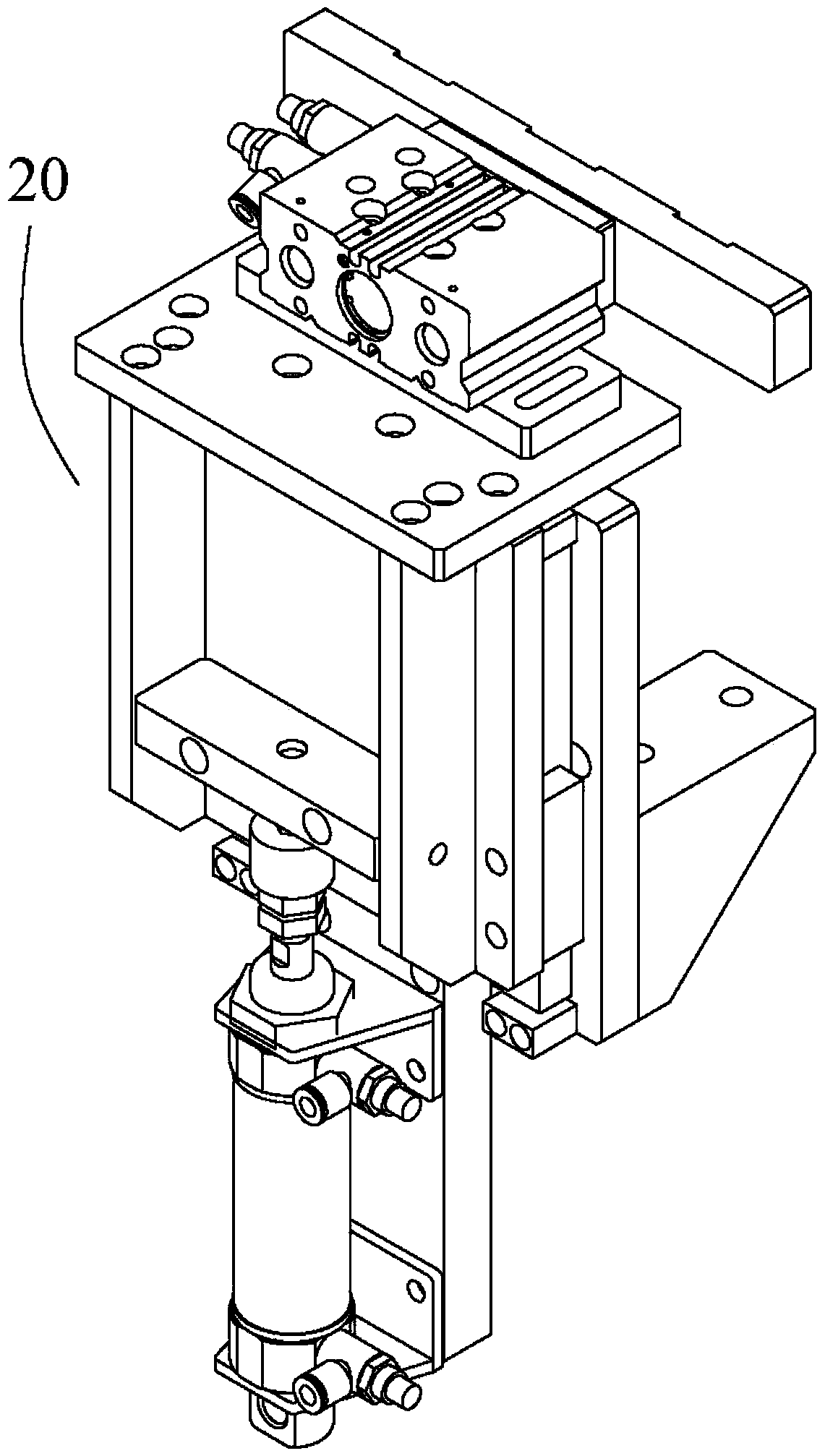

[0025] like figure 1 As shown, the present invention discloses a workbench 100 for automatic inkjet and laser processing positioning. The workbench 100 is used for automatic spraying and laser processing positioning of materials 200 such as glass and marble. The workbench 100 includes: an automatic conveying line 10 for conveying materials, an automatic positioning and clamping device 20, a two-dimensional automatic inkjet platform 30; a positioning processing platform 40 for supporting materials 200, a laser processing system 50, a support platform 60, and an overall Cabinet 70, control box 80, and man-machine interface platform 90.

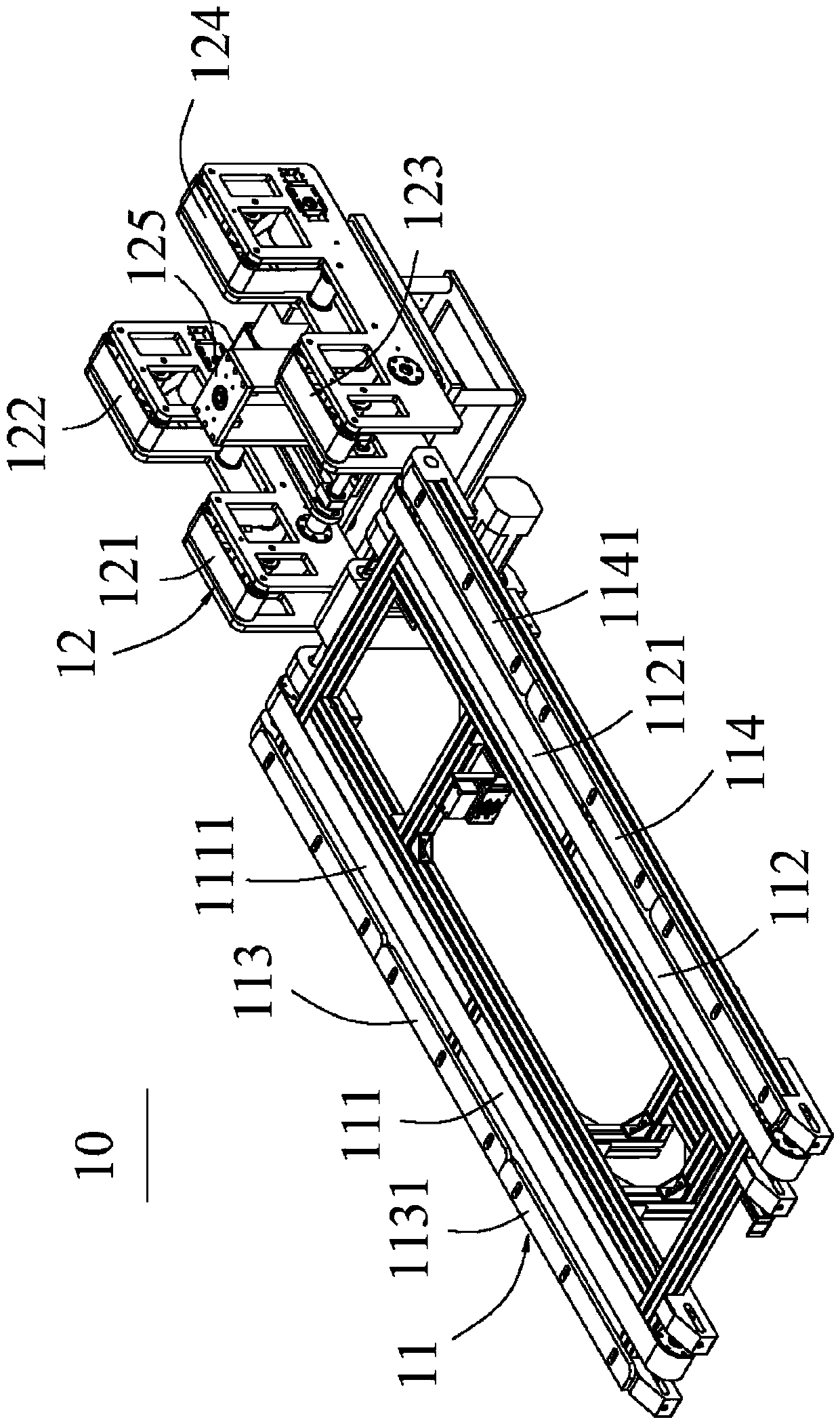

[0026] like figure 2 As shown, the automatic conveying line 10 is the automatic conveying part of the workbench 100 and serves as a mechanism for inputting and outputting materials (such as glass) at the front and back stations of the workbench 100 . The automatic conveying line 10 includes an input device 11 at the front end and an output de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com