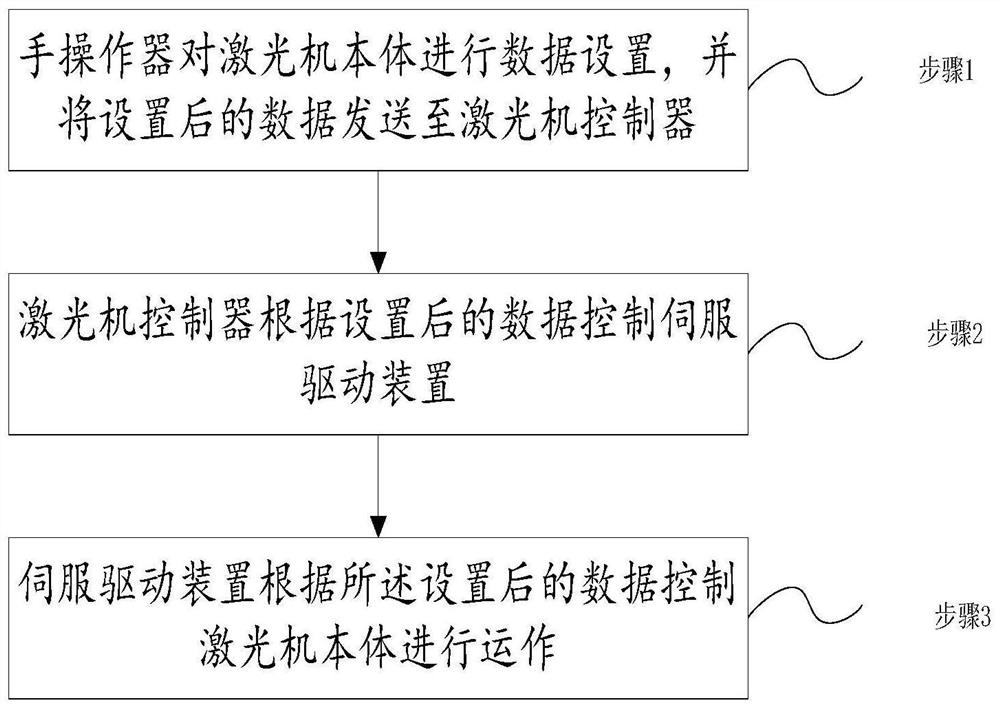

Laser machine control method and system

A control method and control system technology, applied in the field of mechanical engineering control, can solve the problems of single human-computer interaction means, difficult trajectory planning, teaching programming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

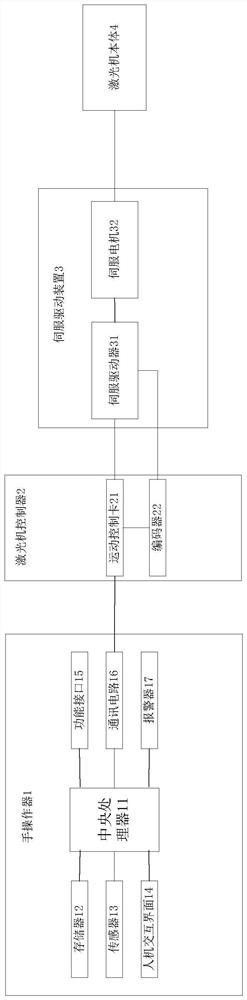

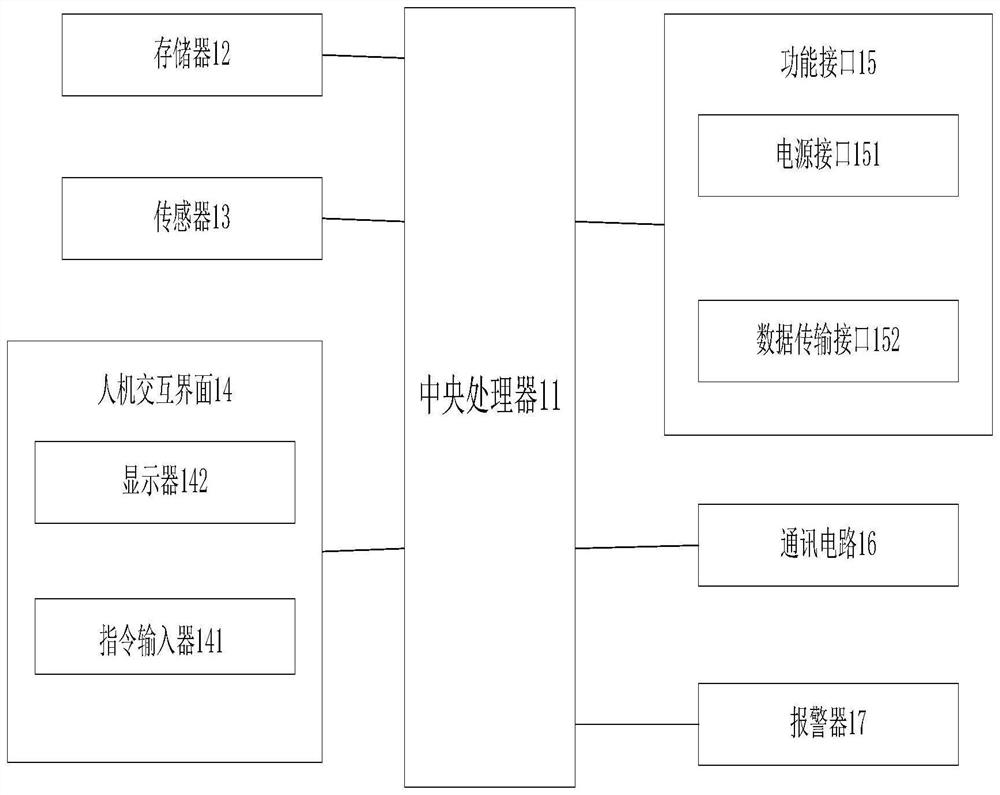

[0072] Example 1, such as figure 2 and image 3 As shown, the hand operator 1 includes a central processing unit 11, a memory 12, a sensor 13, a human-computer interaction interface 14, a functional interface 15 and a communication circuit 16; , the functional interface 15 is electrically connected with the communication circuit 16, and the communication circuit 16 is communicatively connected with the laser machine controller 2. Through the functional interface 15, necessary functions can be provided for the work of the hand manipulator 1; through the central processing unit 11, human The machine-machine interaction interface 14, the sensor 13 and the function interface 15 can provide a rich man-machine interaction platform for the manipulator operator, provide rich interactive means to complete the parameter setting and motion track planning of the laser machine body 4, improve the interaction effect, and then To realize the motion control and operation functions of the la...

Embodiment 2

[0073] Example 2, such as image 3As shown, the human-computer interaction interface 14 includes an instruction input device 141 and a display 142, and the central processing unit 11 is electrically connected to the instruction input device 141 and the display 142 respectively. The instruction input device 141 includes a three-dimensional mouse and a microphone, and also includes buttons and / or a touch screen The three-dimensional mouse and the microphone are all electrically connected to the central processing unit 11 respectively; the buttons are electrically connected to the central processing unit 11, and / or the touch screen is electrically connected to the central processing unit 11, and the three-dimensional mouse is combined with the buttons and / or the touch screen to facilitate The operator performs motion trajectory planning, such as completing the simulation of the laser machine body 4 and the virtual 3D working scene, completing the kinematic modeling of the laser ma...

Embodiment 3

[0074] Embodiment 3, the hand operator 1 also includes an alarm 17; the alarm 17 is electrically connected to the central processing unit 11, through the alarm 17, when a fault occurs during parameter setting and motion trajectory planning, an alarm signal can be sent in time To remind the operator to take corresponding solutions in time to ensure the smooth operation of the entire laser machine and avoid unnecessary losses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com