Battery system structure with chassis cross beam running through battery pack

A battery system and battery pack technology, which is applied to electric power units, transportation and packaging, power units, etc., can solve the problems of no battery pack and shared structural skeleton, and achieve the effects of saving space, improving consistency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

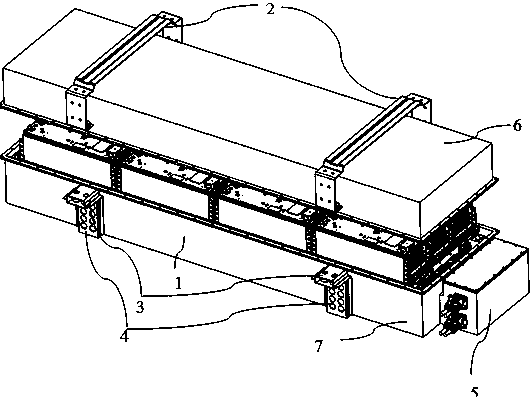

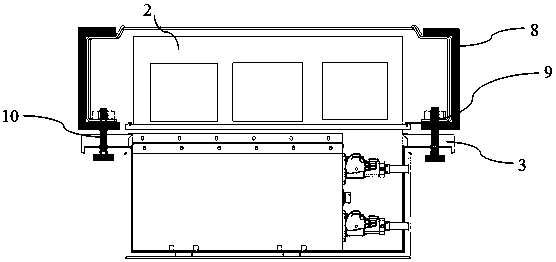

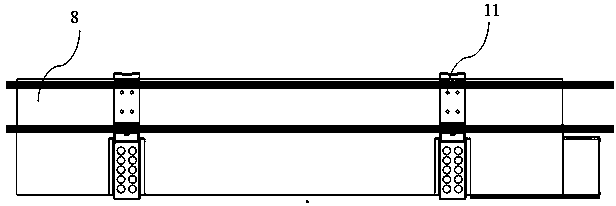

[0025] See attached picture.

[0026] Option 1: The battery system body (1) is composed of traditional structures such as battery modules, fixed module frames, boxes, and box covers. 3) Penetrate through the box wall, weld and fix the through-connection gap and do waterproof treatment. The upper beam (2) is physically connected to the longitudinal beam of the vehicle body, and the nuts are welded at appropriate positions, and the installation bolts penetrate through the beam (3), the chassis longitudinal beam, and are fastened on the upper beam (2). The penetrating beam (3) penetrates the lower box and is integrated with the inverted "several" bracket (4) at the bottom to form the supporting base of the lower module, while the penetrating beam is also the supporting base of the upper module. At the same time, the penetrating beam is also used as a structural part of the chassis, connecting the left and right longitudinal beams, and playing a structural role similar to the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com