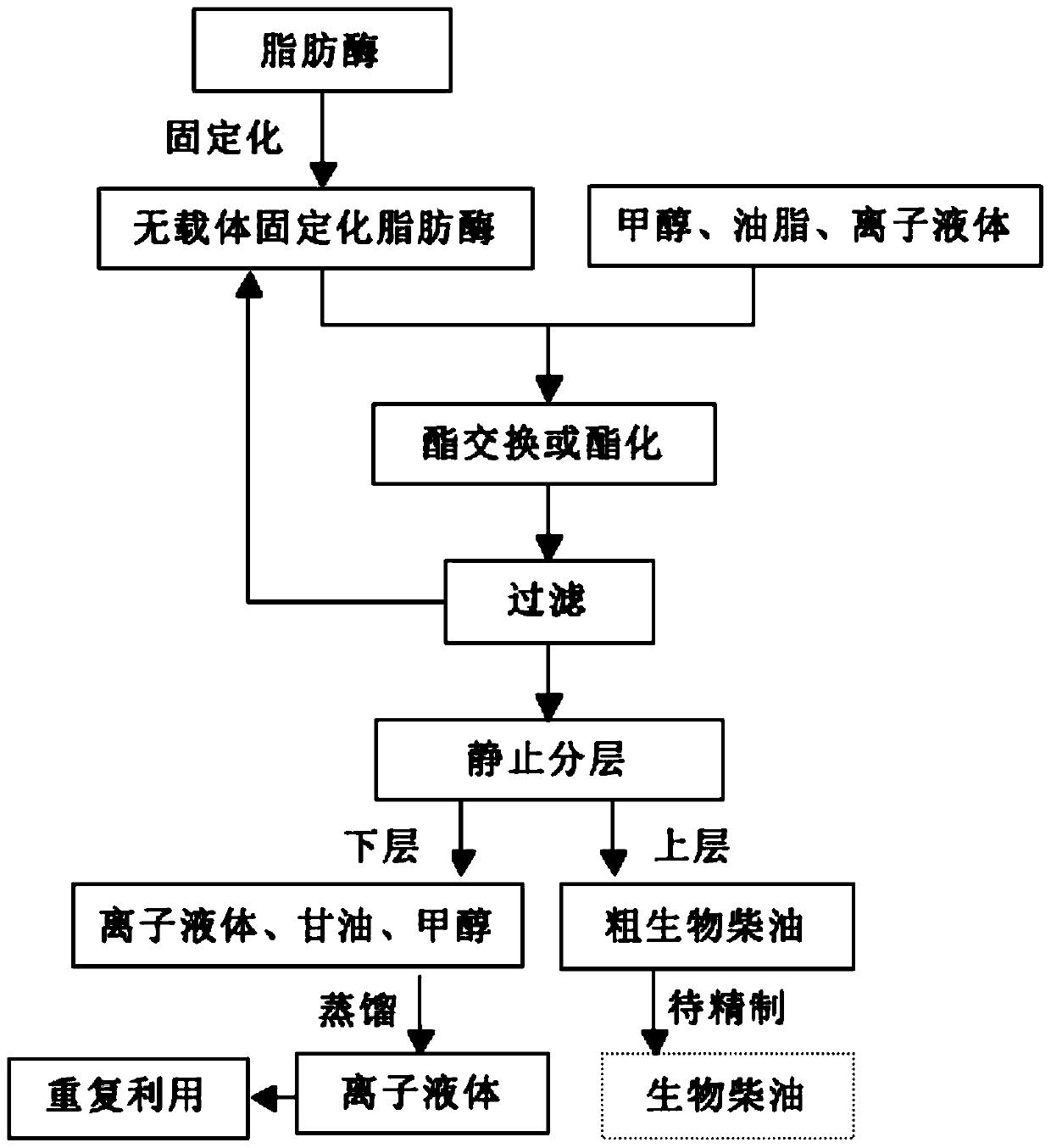

A method for preparing biodiesel catalyzed by carrier-free immobilized lipase under ionic liquid system

A carrier-free immobilization and ionic liquid technology, applied in biofuels, hydrolytic enzymes, fermentation, etc., can solve the problems of high lipase immobilization cost, low oil conversion rate, and easy decline in enzyme activity, and achieves industrial application. Good stability and high activity per unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of carrier-free immobilized lipase:

[0030] ① Dissolve the free Rhizomucor miehei lipase and bovine serum albumin (BSA) protective agent with a mass ratio of 5:1 in a phosphate buffer solution with a pH of 5.8 and a molar concentration of 0.1mol / L to make 10mg / mL For enzyme solution, take 50mL of enzyme solution, add 100mL of 0.4mol / L calcium chloride aqueous solution, mix well, quickly add an equal amount of equimolar sodium carbonate solution of 100mL, stir magnetically at 4-25°C for 1min, and stand still for 2h , through co-precipitation, the free enzyme molecules are evenly dispersed in CaCO 3Inside the particulate template agent, stable spherical templated calcium carbonate particles are formed; then add 150mL of saturated ammonium sulfate solution precipitant dropwise, shake slowly at 4-25°C for 1-2min, let stand for 2h, and carry out lipase coagulation precipitation, 3000rpm Centrifuge and wash for 3 minutes to obtain coprecipitated particles;

[0...

Embodiment 2

[0036] Preparation of carrier-free immobilized lipase:

[0037] ①Dissolve free Candida antarctica lipase and bovine serum albumin (BSA) protective agent with a mass ratio of 6:1 in pH=7, molar concentration of 0.2mol / L phosphate buffer to make 11mg / mL enzyme liquid. Take 50mL of enzyme solution, add 100mL of 0.4mol / L calcium chloride aqueous solution, mix evenly, quickly add the same amount of equimolar sodium carbonate solution 100mL, stir magnetically for 1min at 4~25℃, let it stand for 2h, pass Co-precipitation allows free enzyme molecules to be evenly dispersed inside the CaCO3 particle template to form stable spherical templated calcium carbonate particles; then add 180mL of saturated ammonium sulfate solution precipitant dropwise, shake slowly at 4-25°C for 1-2min, and then statically Set aside for 2 hours, carry out coagulation and precipitation of lipase, centrifuge and wash at 3000rpm for 3 minutes to obtain coprecipitated particles;

[0038] ② Add 1ml of 50mmol / L d...

Embodiment 3

[0043] Preparation of carrier-free immobilized lipase:

[0044] ①Dissolve free Penicillium extensa lipase and bovine serum albumin (BSA) protective agent with a mass ratio of 10:1 in pH=8, molar concentration of 1mol / L phosphate buffer to prepare 15 mg / mL enzyme solution. Take 50mL of enzyme solution, add 100mL of 0.5mol / L calcium chloride aqueous solution, mix evenly, quickly add the same amount of equimolar sodium carbonate solution of 100mL, stir magnetically for 1min at 4-25℃, let stand for 2h, pass Co-precipitation allows the free enzyme molecules to be evenly dispersed inside the CaCO3 particle template to form stable spherical templated calcium carbonate particles; then add 200mL of saturated ammonium sulfate solution precipitant dropwise, shake slowly at 4-25°C for 1-2min, and then statically Set aside for 2 hours, carry out coagulation and precipitation of lipase, centrifuge and wash at 3000rpm for 3 minutes to obtain coprecipitated particles;

[0045] ②Add 1.2ml of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com