Permanent magnet synchronization traction machine

A synchronous traction machine and permanent magnet technology, applied in the field of traction machines, can solve the problems of complex manufacturing process, far distance between force point and support point, long processing time, etc., and achieve simple and reliable structural design, easy processing and Easy assembly, installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

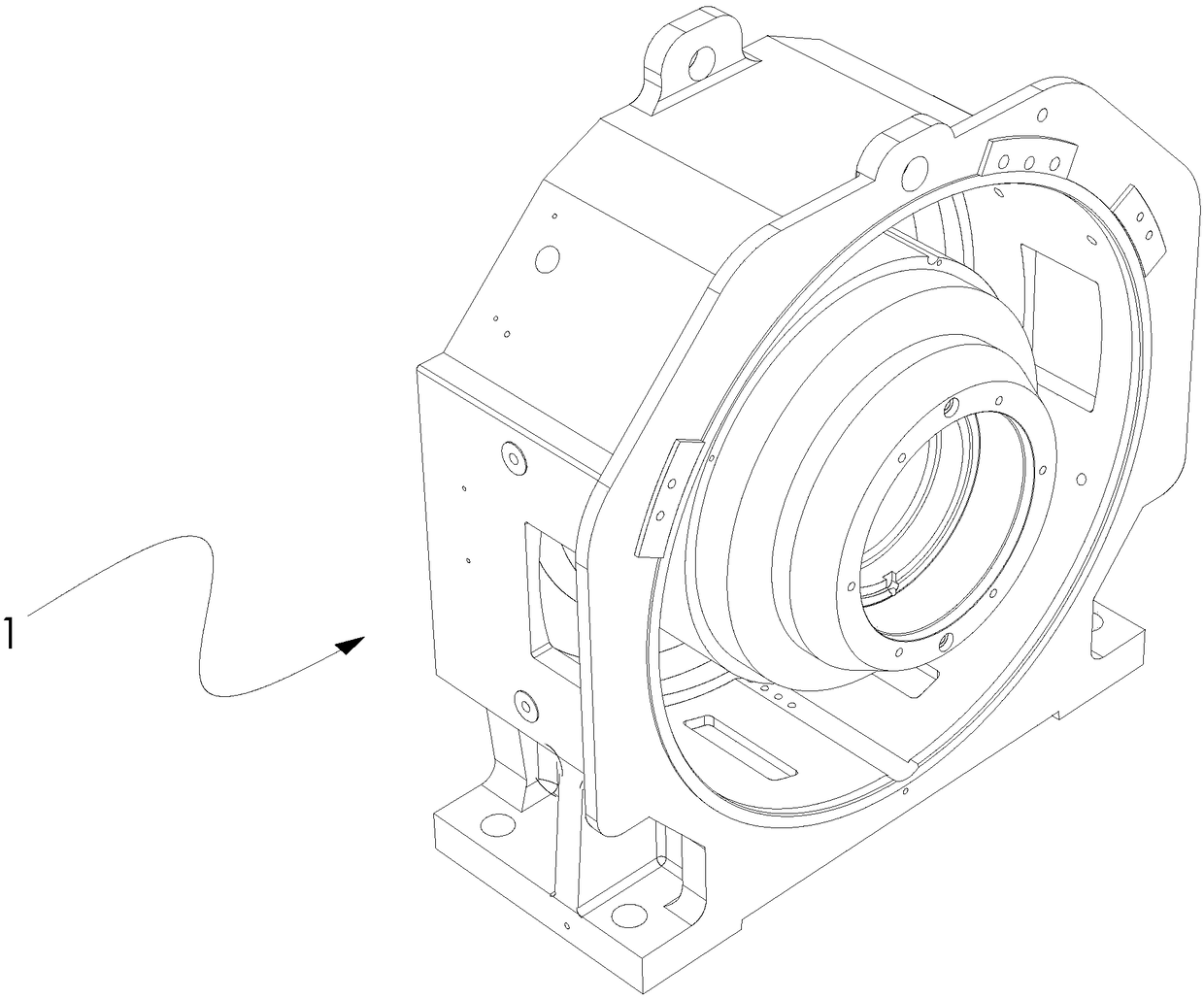

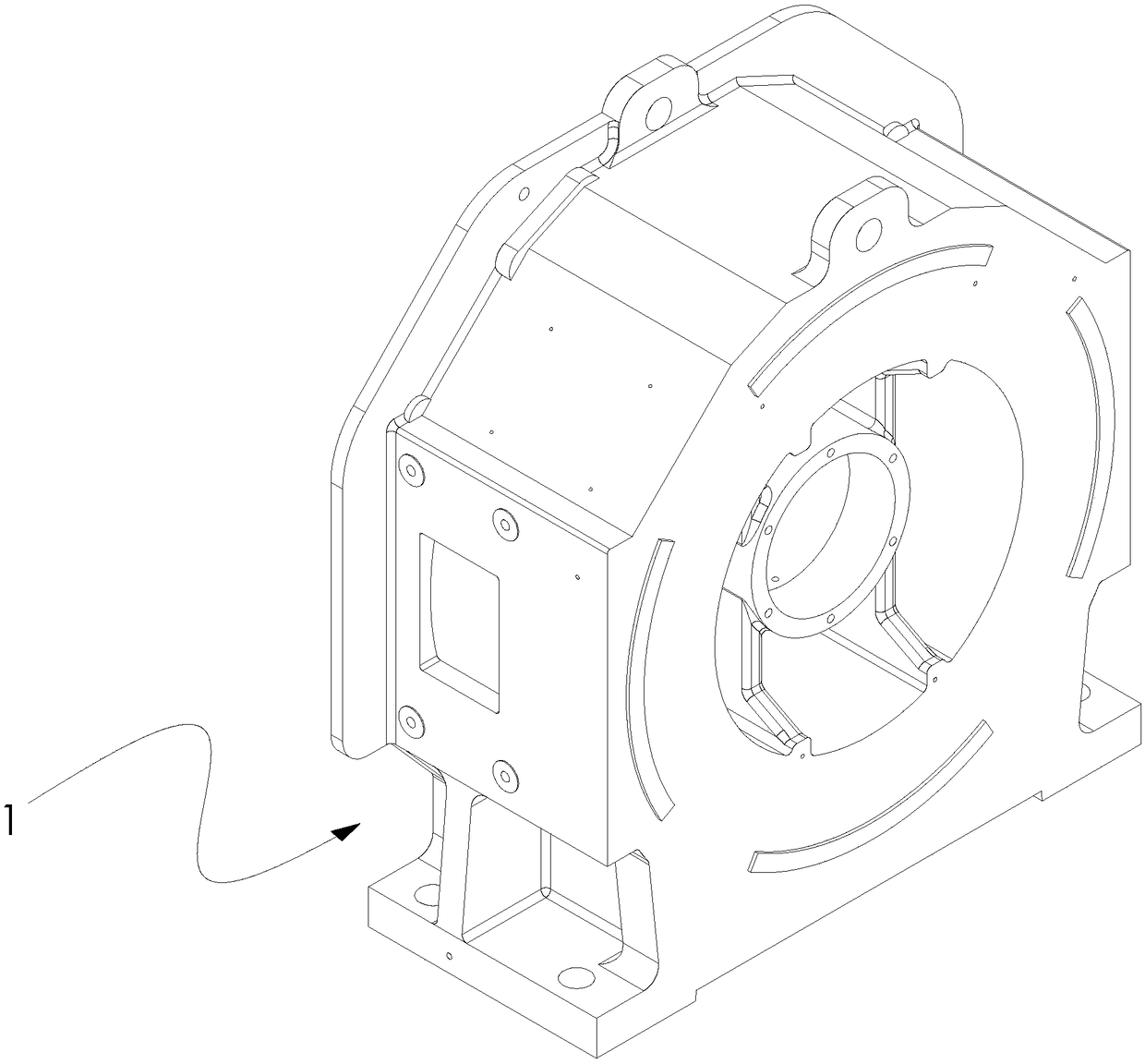

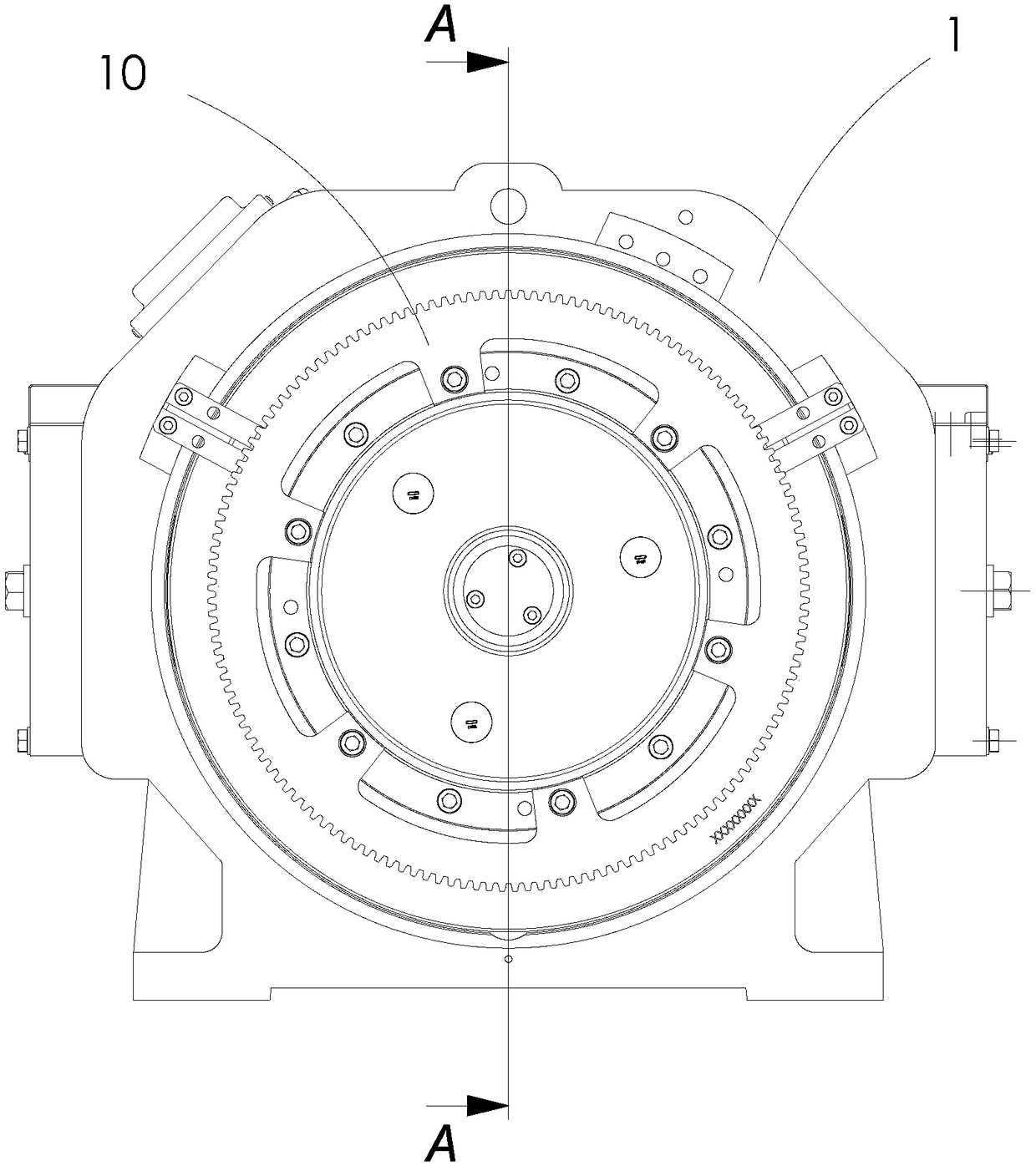

[0033] refer to Figure 5-Figure 10 , a permanent magnet synchronous traction machine in this embodiment includes a traction machine base 1, a stator assembly 12, a rotor assembly 11 matched with the stator assembly 12, a traction wheel 10 and a shafting assembly. The structure of the permanent magnet synchronous traction machine in this embodiment is applicable to the welding machine base and the casting machine base, and the welding machine base will be described in detail below.

[0034] The traction machine base 1 in this embodiment is a welded base, including a bottom plate 14 at the bottom, side plates 25 on both sides of the bottom plate 14, and a support plate 15 connecting the side plates 25. The support plate 15 is provided with a Piping 16 of the shafting assembly. The side panels 25 include left and right panels located at both ends of the support panel 15 .

[0035] The side of the pipe 16 and the support plate 15 away from the side plate 25 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com