Anchoring strength testing device

A strength test and anchoring technology, which is used in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of smashing people, direct drop of anchoring components, pits, etc., to improve safety, safe and reliable use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

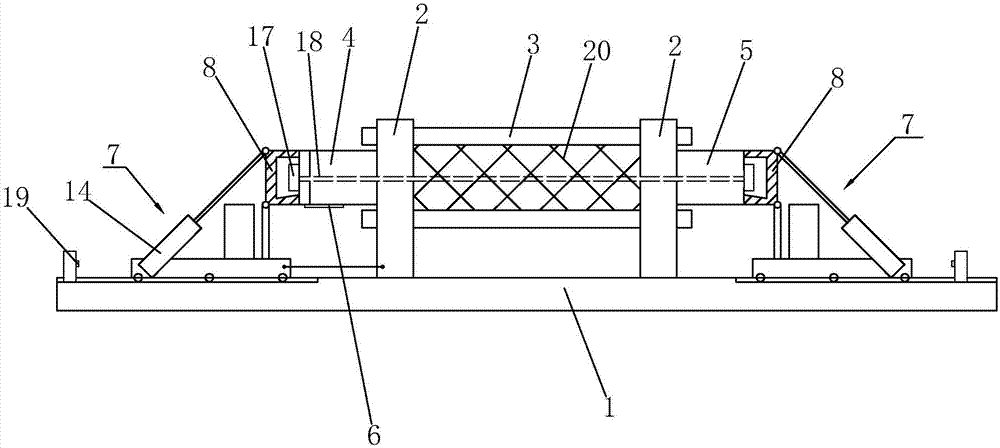

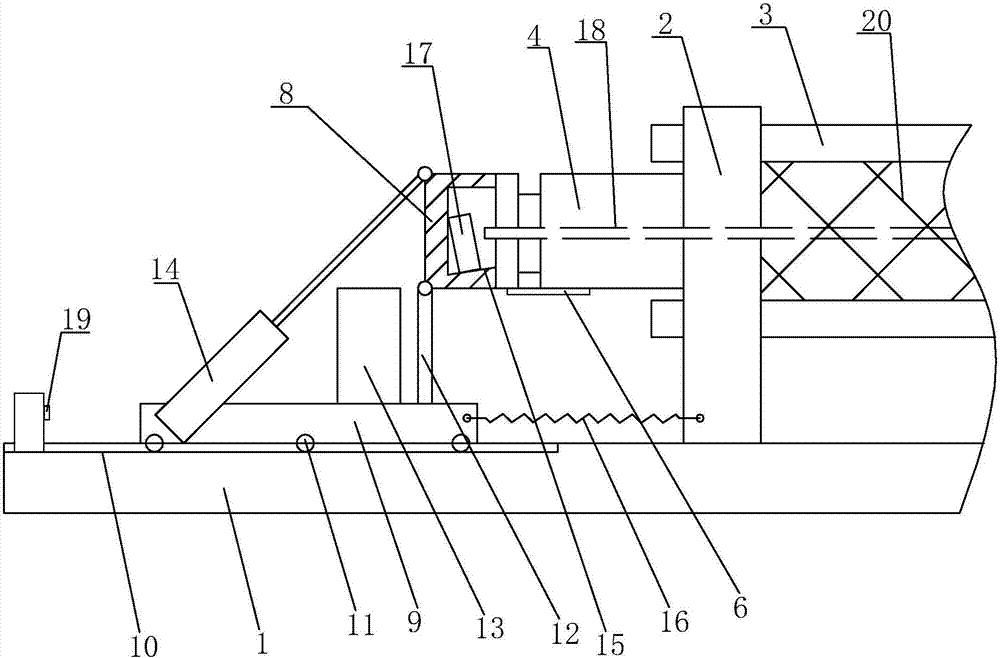

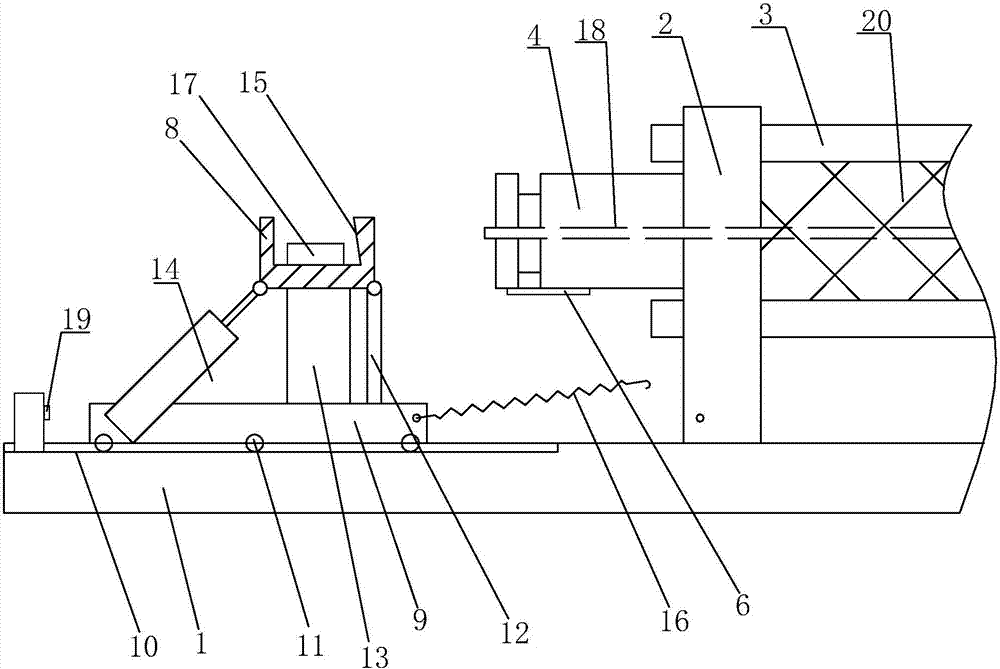

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] This embodiment discloses a kind of anchor strength test equipment, such as figure 1 As shown, it includes a base 1, and the base 1 is provided with two opposite and parallel support bases 2, a number of support rods 3 are connected between the two support bases 2, and a protective net 20 that can be opened from the side or above is installed. A jack 4 is fixed on the left support base 2, and the jack 4 is a through-hole jack; the other support base 2 is fixed with a load sensor 5. When doing the anchor strength test, the steel strand 18 passes through the jack 4, the support seat 2, and the load sensor 5, and the two ends of the steel strand 18 are connected to the anchor assembly 17, and the anchor assemblies 17 at both ends are in conflict with the jack 4 and the load sensor 5 respectively. The end face of the anchor assembly 17 is applied by the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com