Attached support structure

A support structure and support plate technology, applied in the direction of house structure support, house structure support, building structure, etc., can solve the problems of increased lifting force, falling of the frame body, cumbersome process, etc., to reduce installation stress and overturning moment, Easy installation and operation, simple structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

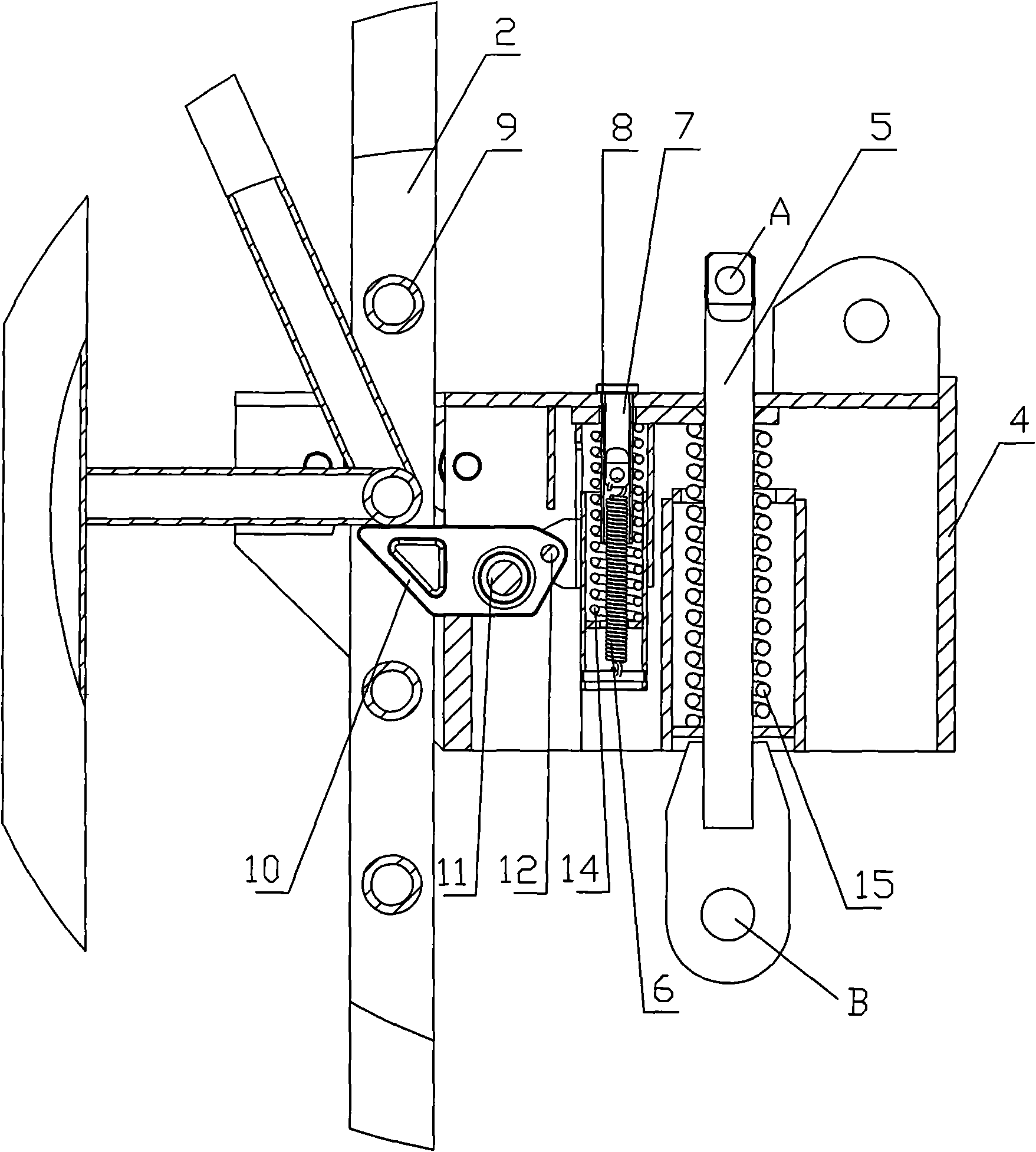

[0028] The present invention will be further described below in conjunction with accompanying drawing.

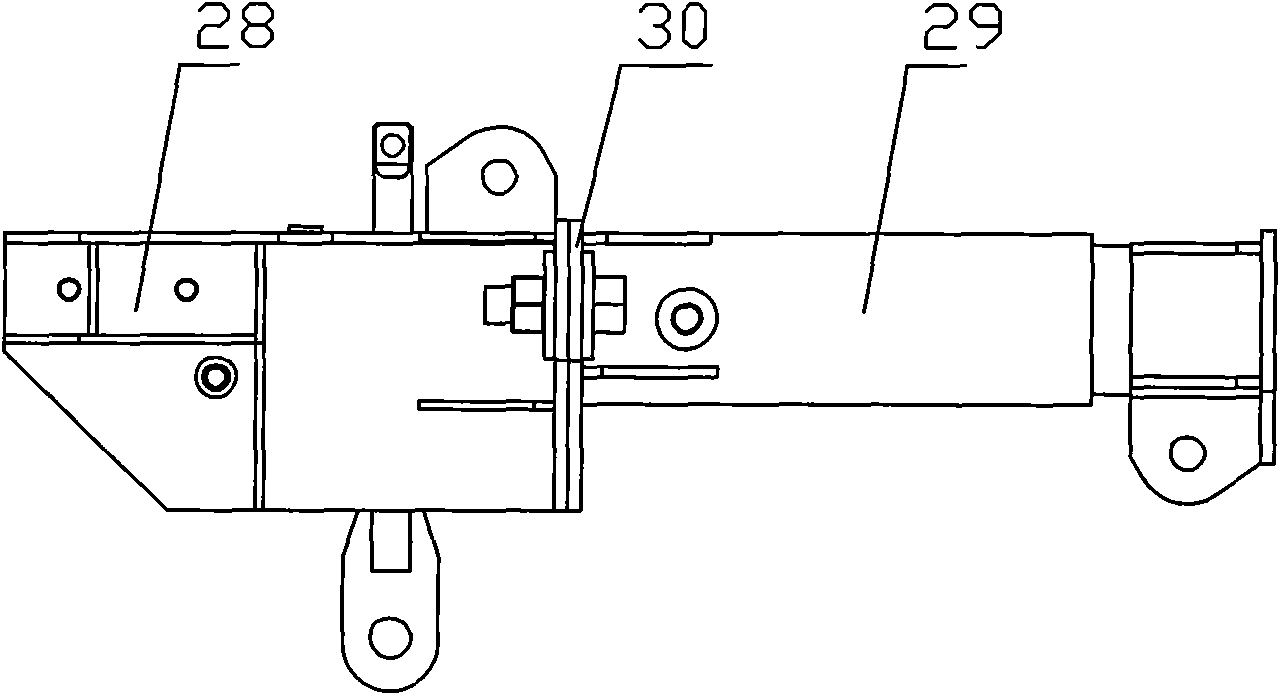

[0029] Attachment support structure of the present invention, see figure 1 , it is made up of guide seat 28 and attachment support 29, is respectively provided with connection plate 30 on two parts, and connecting bolt passes two connection plates and guide seat and attachment support are fixedly connected. The present invention has two major technical innovations: 1. Through the technical innovation of the attached support, the stepless adjustment of the connection distance between the frame and the outer wall of the building is realized; 2. Through the technical innovation of the guide seat, the frame can be adjusted under any working conditions. Fully automatic anti-fall function. This is explained separately below.

[0030] 1. Technological innovation of attachment support

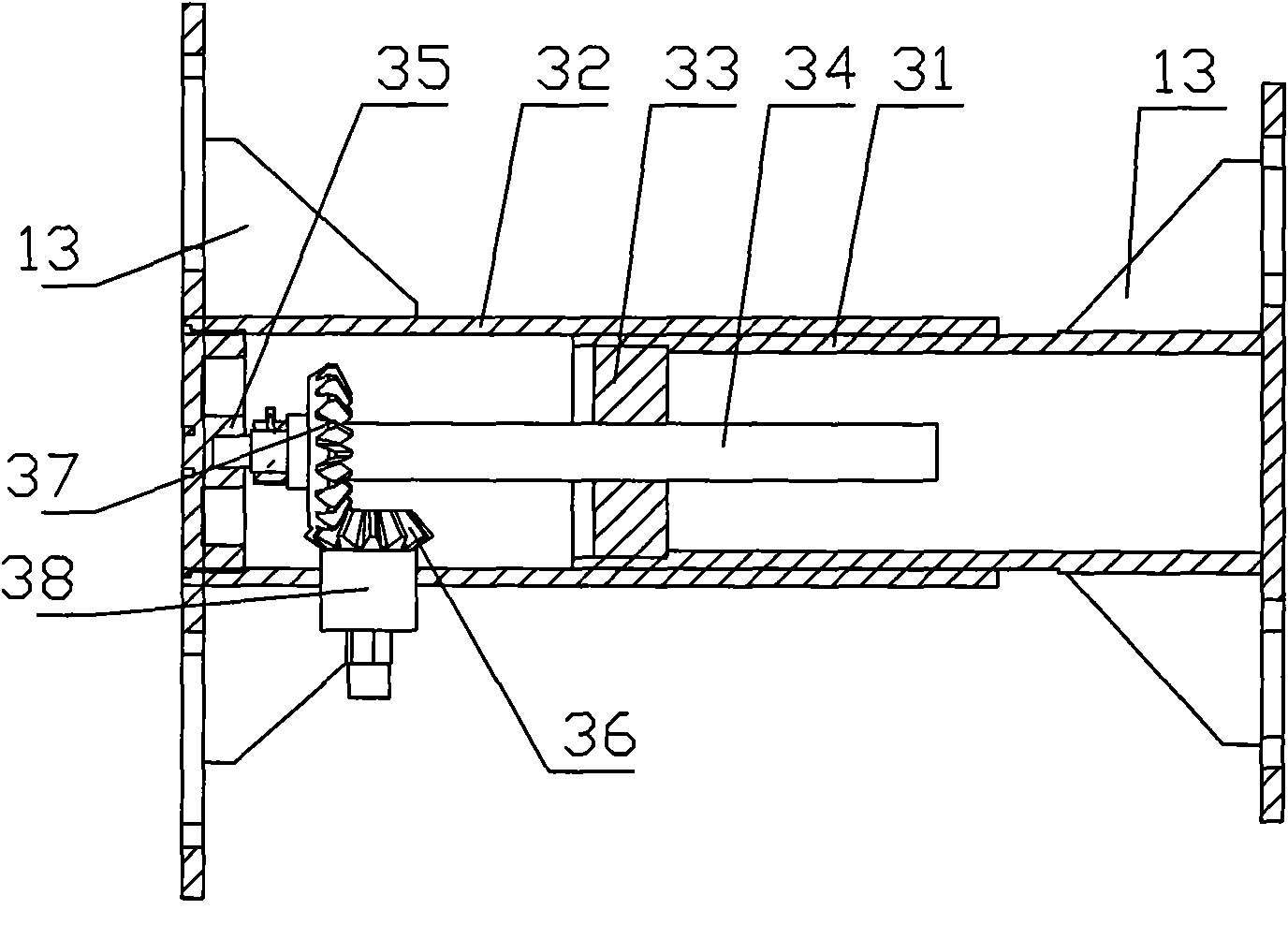

[0031] see figure 2 , the attachment support 29 includes an inner cylinder 31 and an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com