Fuel cell unit structure and electric pile assembly

A fuel cell unit and fuel technology, applied in the direction of fuel cell grouping, fuel cells, solid electrolyte fuel cells, etc., can solve problems affecting MEA performance, affecting assembly speed, MEA exposure, etc., to reduce fuel and oxidant leakage, reduce Possibility of damage and contamination, effects of improved assembly speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

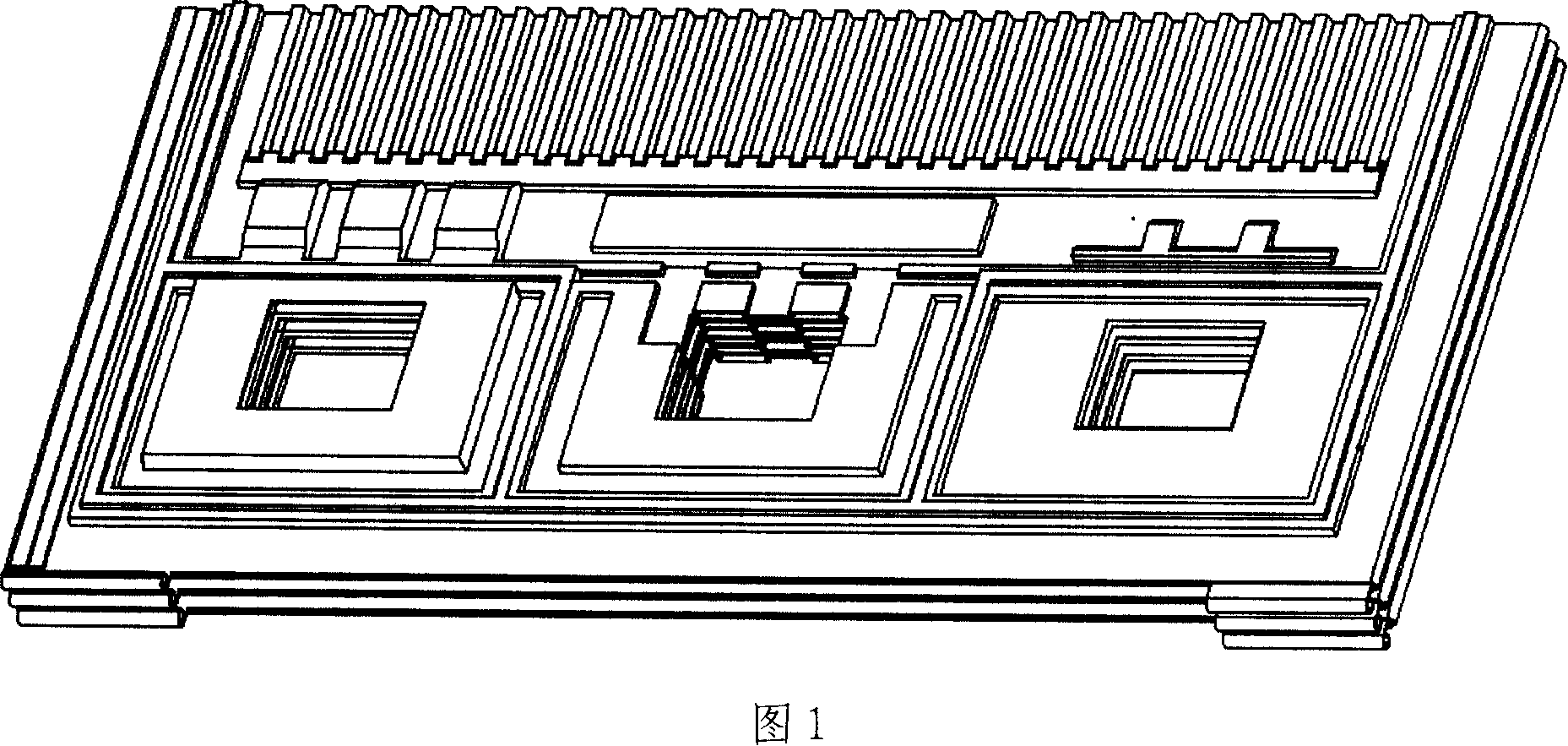

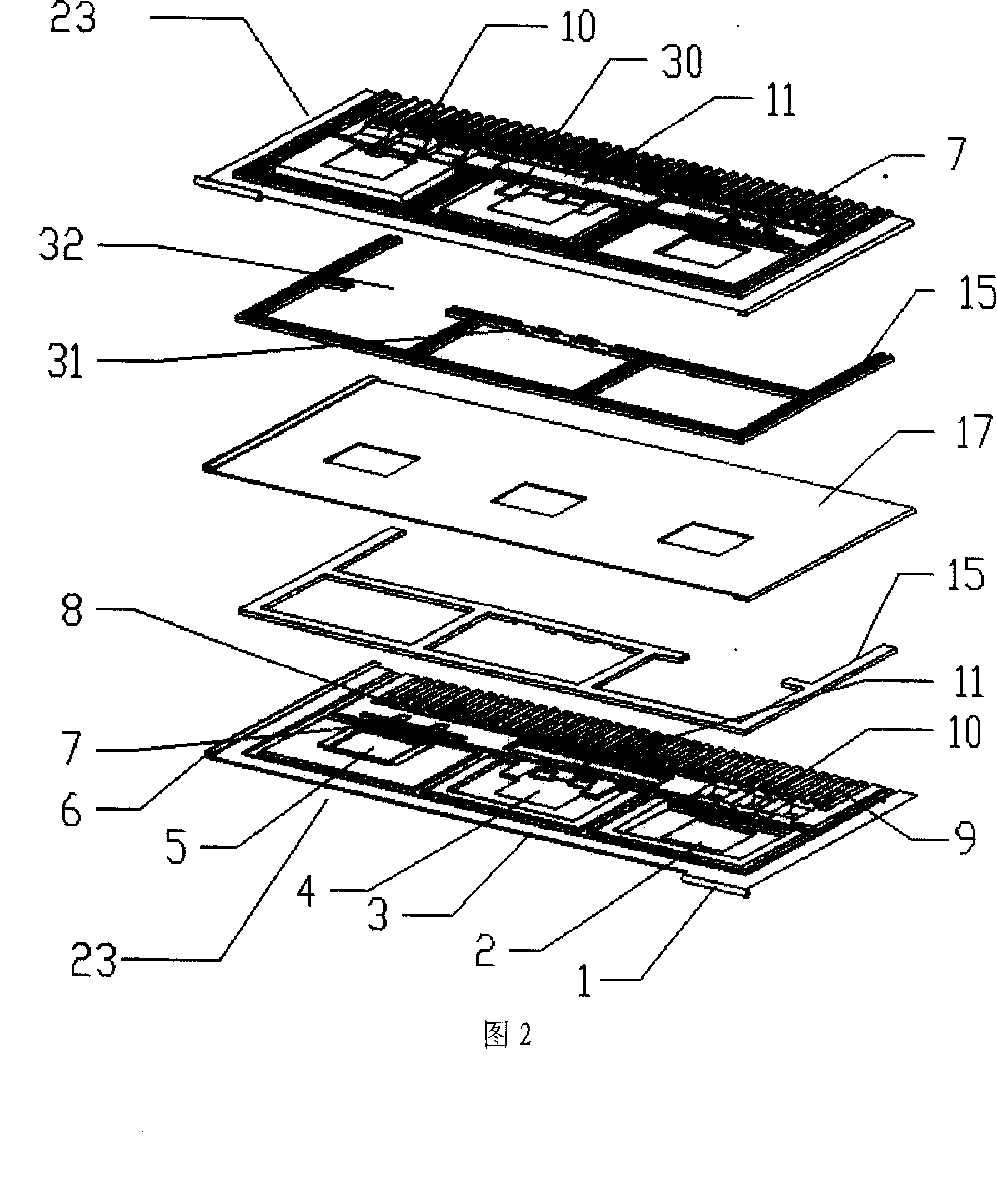

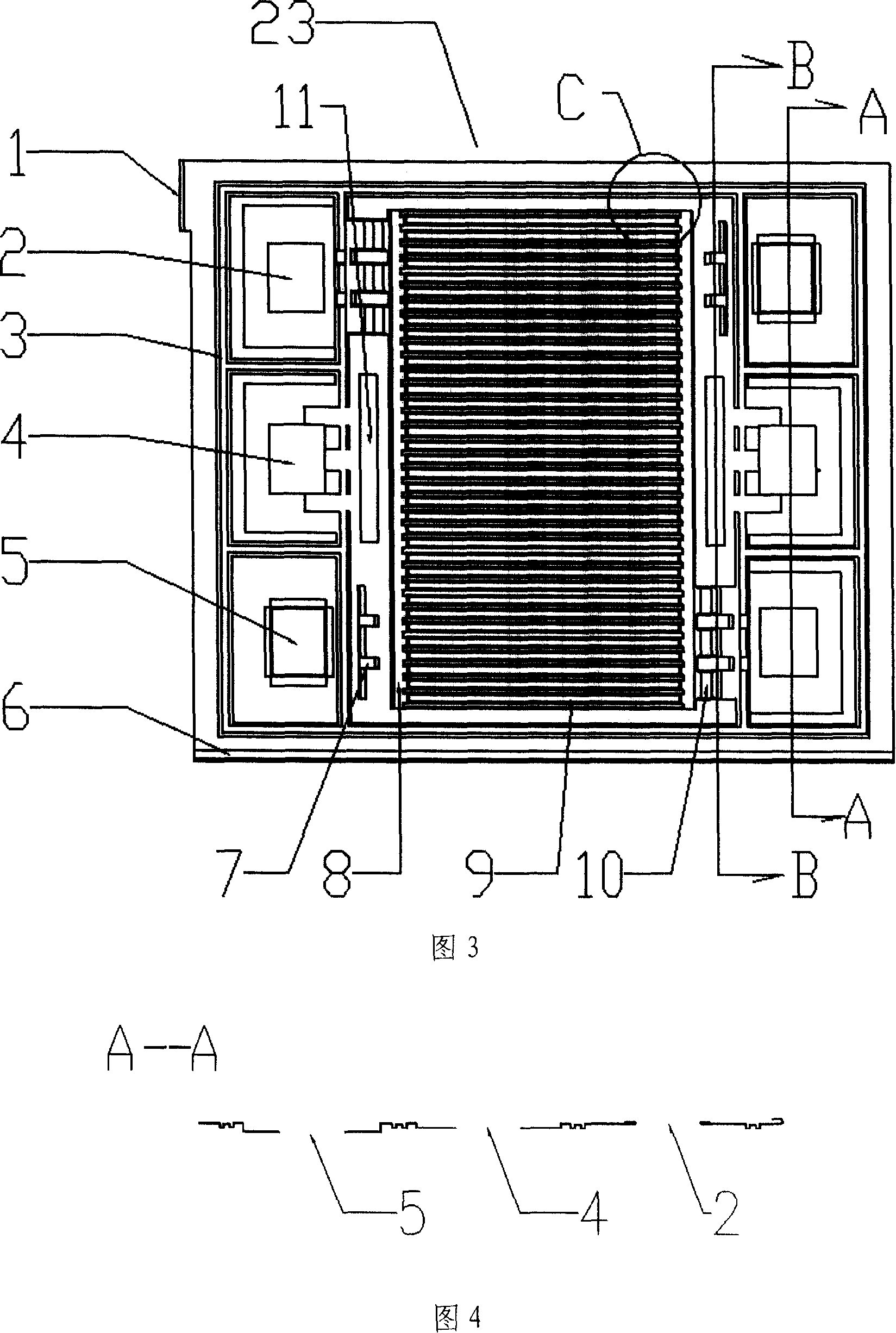

[0040] The unit embodiment of the present invention is shown in Fig. 2 to Fig. 15 . Fig. 1 is a partial perspective view of a multi-cell battery assembled by the unit of the present invention. The flow field form takes parallel grooves as an example, but it is not limited to the flow field structure of parallel grooves. This design is also applicable to other common flow fields.

[0041]As shown in Fig. 2 and Fig. 3, the fluid public channels 2 and 5 are used for the delivery of fuel and oxidant, and the MEA17 is encapsulated on the inside of two metal plates 23, and the side of the metal plate 23 in contact with the MEA17 forms the fluid of oxidant or fuel Channel, that is, the inner side of the unit structure, there is a sealing inner glue line 15 between the electrode MEA17 and the metal pole plate 23, and a gap 32 is provided on the inner glue line 15 at the position of the bridge 10, and it can also be used between the MEA17 and the metal pole plate 23 The adhesive secur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com