Light element and preparation method, and its backlight mould set

A technology of light guide element and backlight module, applied in the direction of optical element, diffuser element, light guide, etc., can solve the problems of light energy loss, boundary glow line and dark line generation, increase assembly time and cost, etc., to increase mechanical strength. , The effect of improving optical defects and reducing light energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

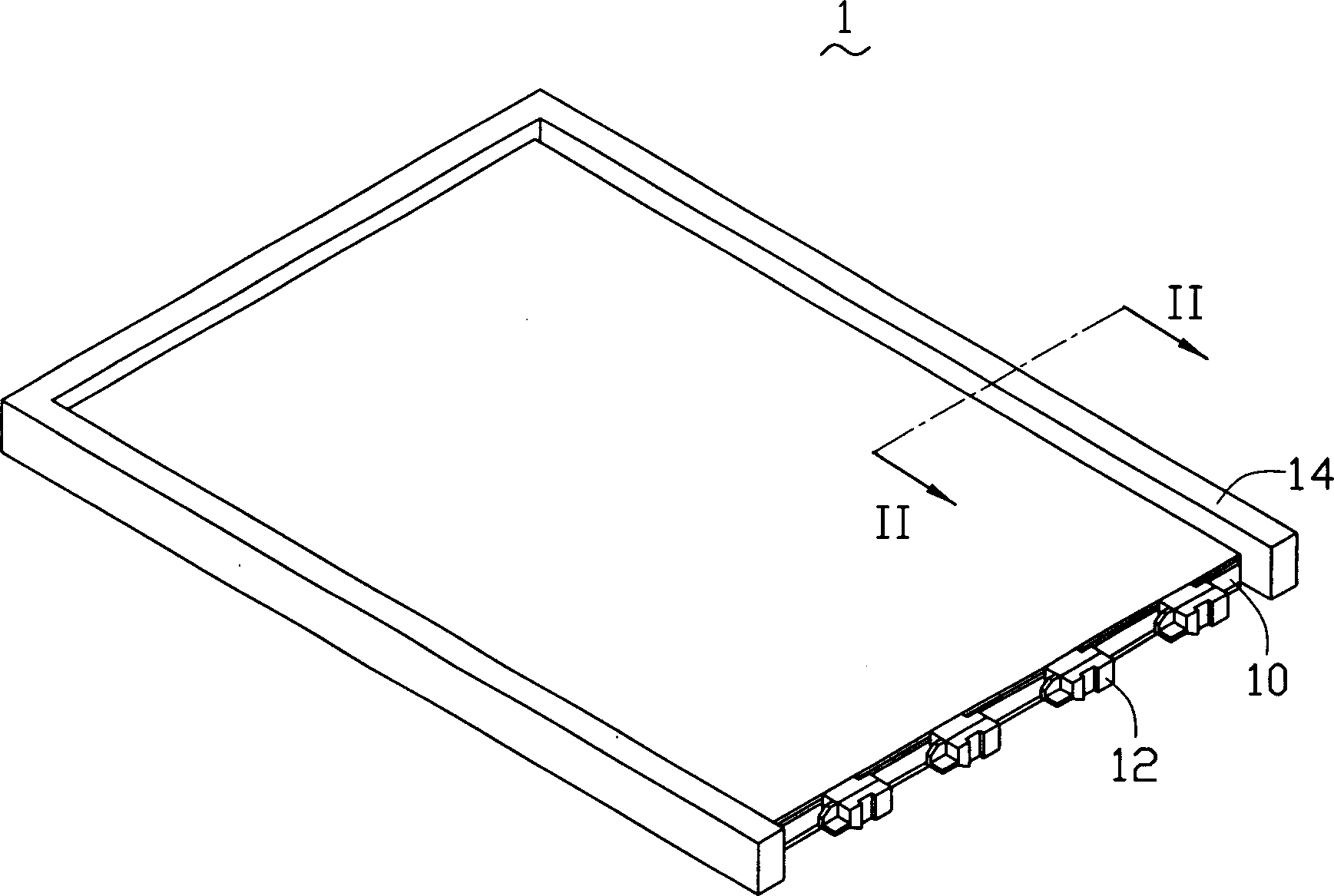

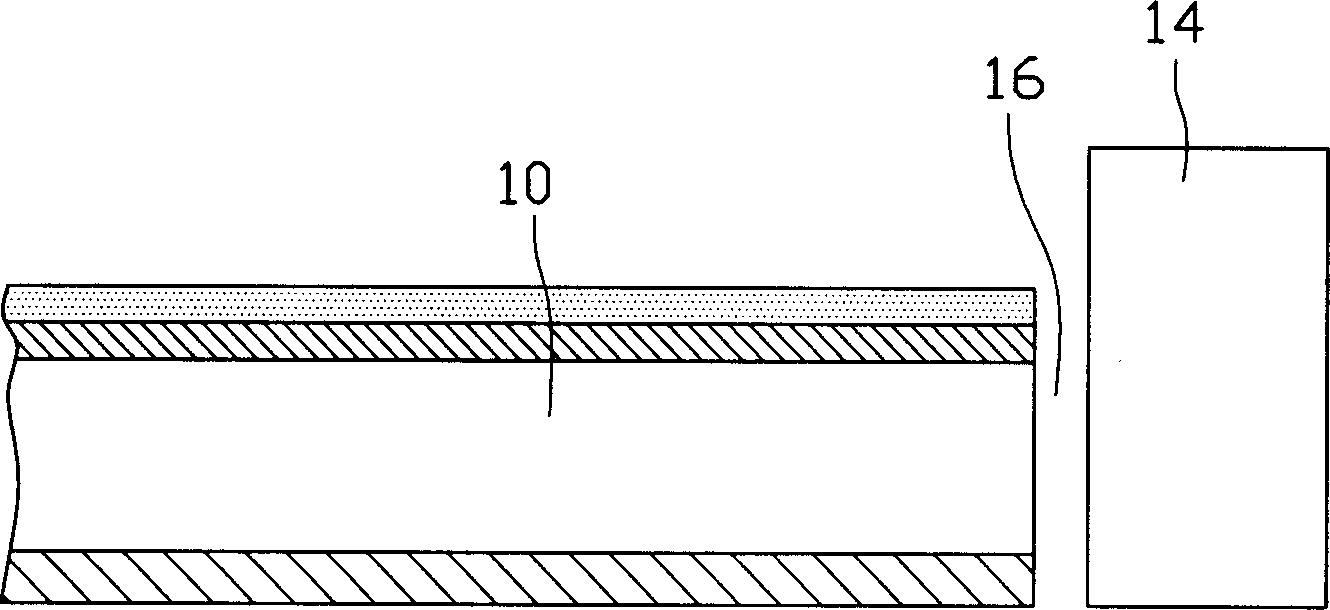

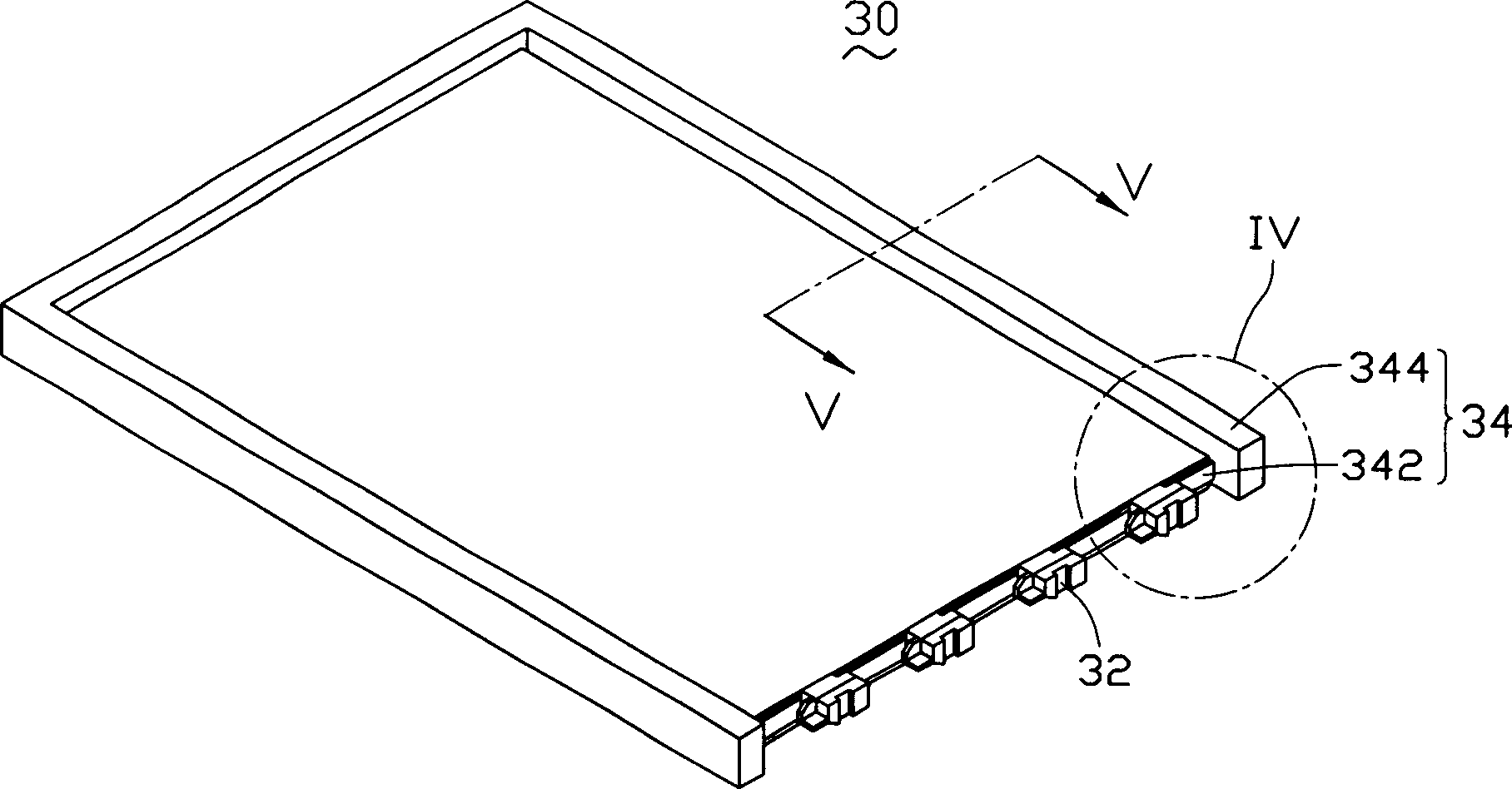

[0035] The light guide element and the backlight module using the light guide element of the present invention will be further described in detail below with reference to the drawings and multiple embodiments.

[0036] Please refer to image 3 , Figure 4 and Figure 5 The first embodiment of the present invention provides a light guide element 34, which includes a light guide plate 342, and the light guide plate 342 includes an incident surface 3422, an exit surface 3424 connected to the incident surface 3422, and an exit surface 3424 opposite to the exit surface 3424. The corresponding reflective surface (not shown in the figure), and the three sides 3426 except the incident surface 3422 ; and a frame 344 , the frame 344 is integrated with the three sides 3426 of the light guide plate.

[0037] Wherein, in this embodiment, the light guide plate 342 is made of transparent polycarbonate, and the frame 344 is made of white polycarbonate with high reflection coefficient. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com