Beam-column joint connecting device with inclined strut for fabricated steel structure special-shaped column

A node connection and steel structure technology, applied in the direction of building structure, construction, etc., can solve the problems that affect the construction speed and quality, affect the force performance of nodes, and not easy rigid connection, etc., to improve the assembly speed and quality, and construction speed And the effect of quality improvement and fastening work is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

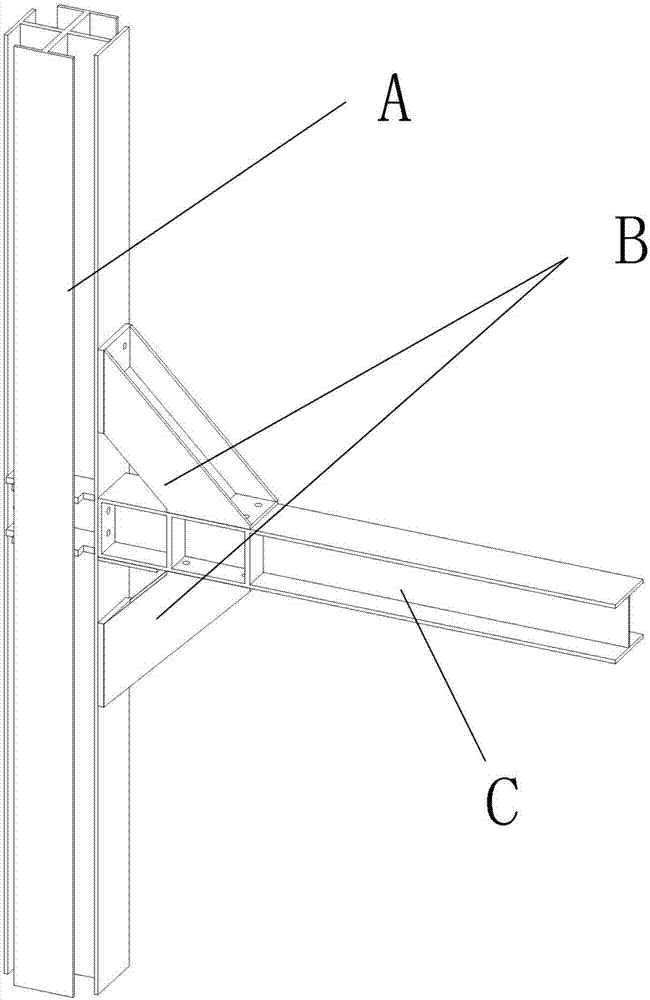

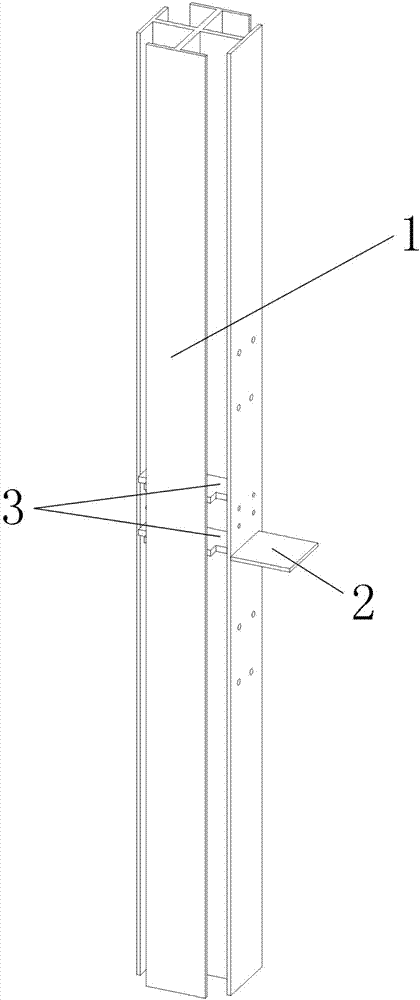

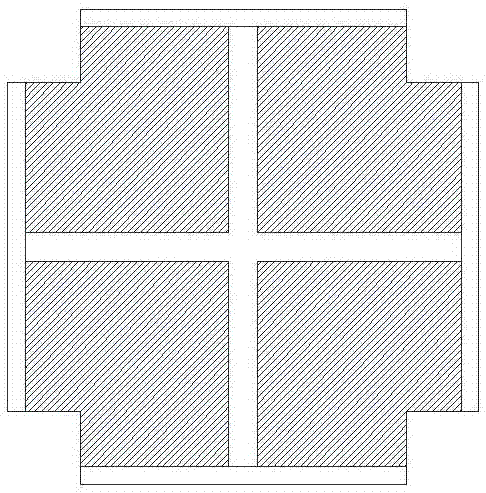

[0023] as attached figure 1 As shown, the column and the beam are connected by bolts, and the end plate (5) in the beam is connected to one side of the cross-shaped special-shaped column (1) by bolts. The braces are connected to the beams and columns by bolts, and the beams and columns are connected to the bottom plate (8) of the braces by bolts. This design enables the bolts not only to bear friction, but also to bear tension, which further enhances the bearing capacity of the joints. In the assembled steel structure special-shaped column-beam-column joint connection device with diagonal braces, the supporting plate (2) and the H-shaped steel beam (4) have the same width, and the end plate (5) and the column have opposite positions and the same size. Bolt hole. The mid-slab (8) of the braces and the beams and columns respectively have bolt holes with corresponding positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com