Processing method of concrete honeycomb floor and its used structure box

A processing method and concrete technology, which is applied to floors, building components, building structures, etc., can solve the problems of large space occupation, small bearing capacity, and small span, and achieve the effects of simple construction, increased hollow rate, and reduced engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation.

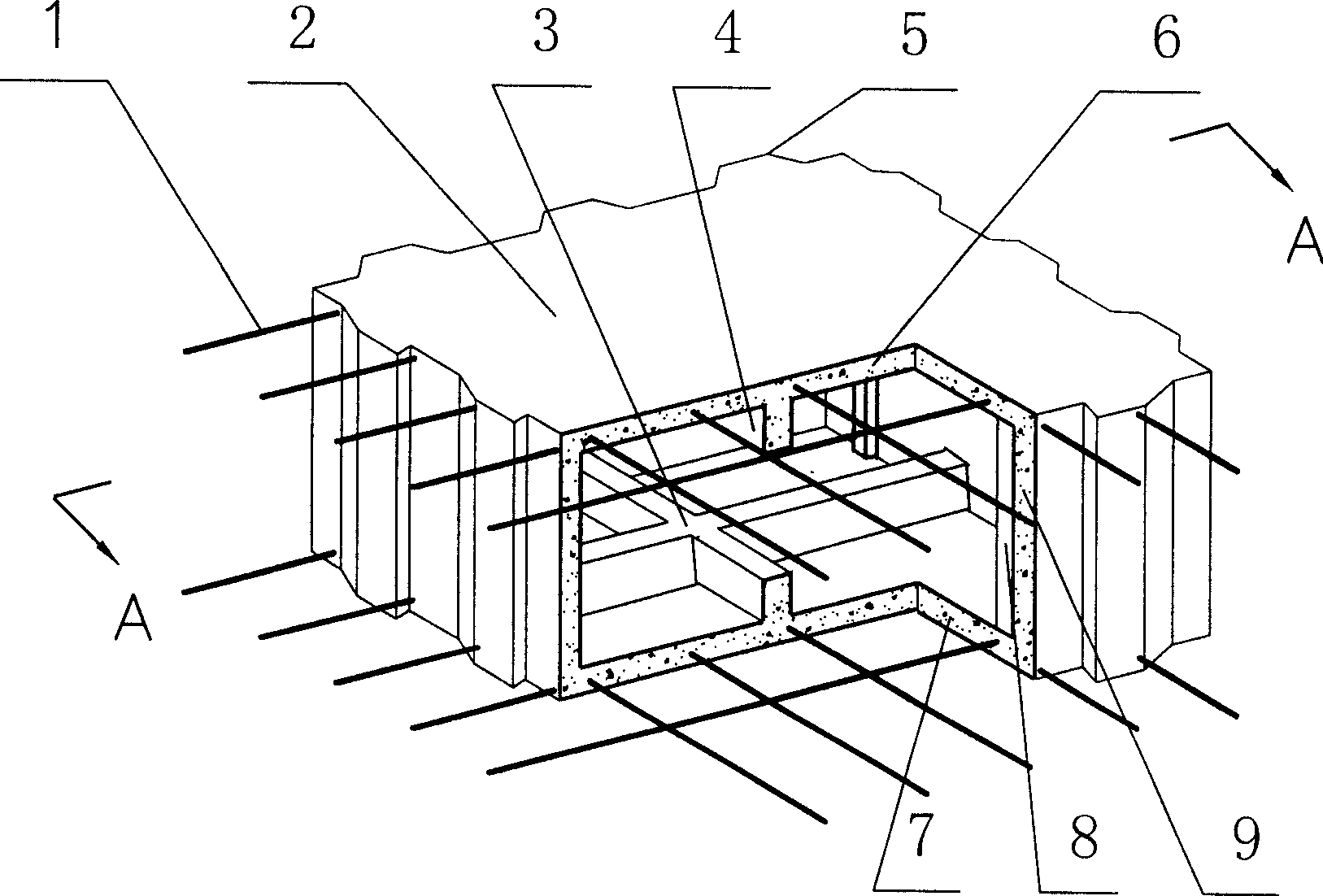

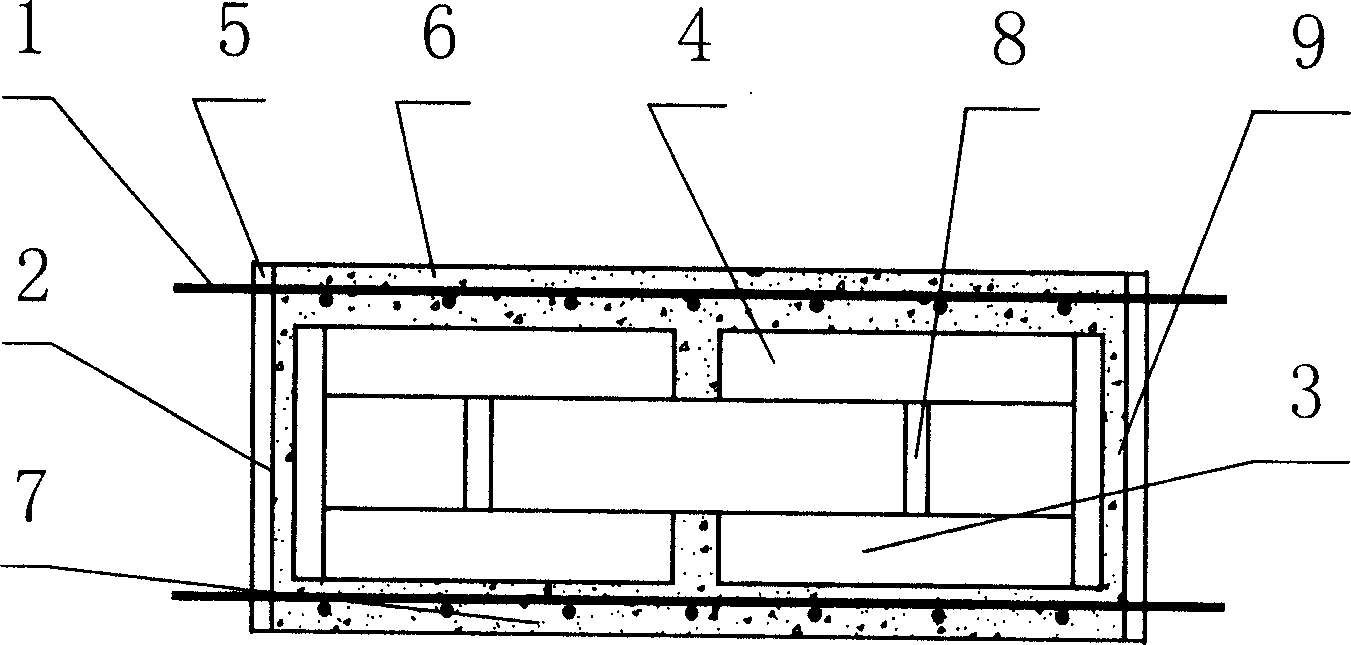

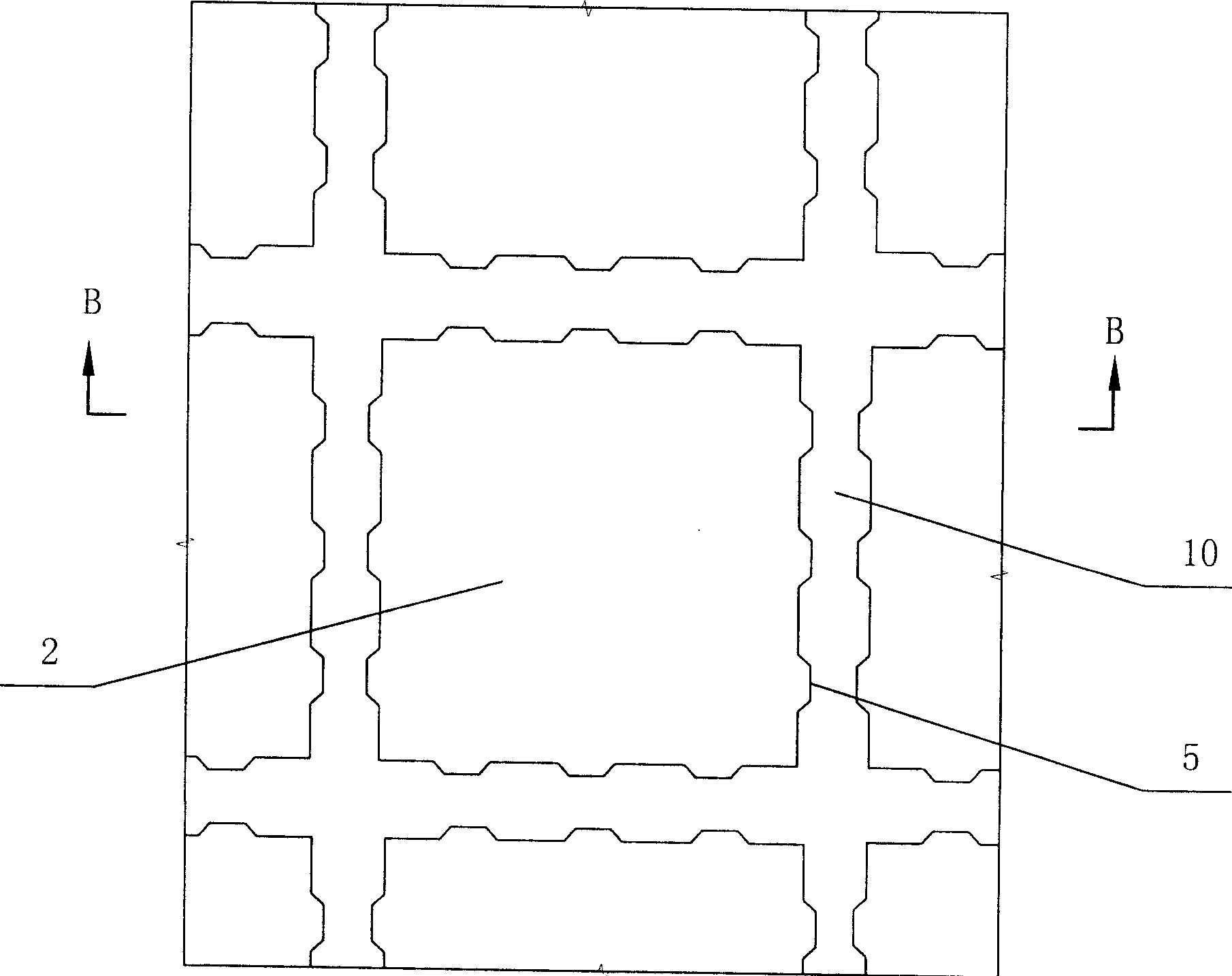

[0019] by attaching figure 1 And attached figure 2 It can be seen that the structural box used for the floor in this scheme is a hollow and sealed box (2) made of concrete, and there are crosses in the bottom plate (7) and top plate (6) of the box body (2). And stretch out the structural box reinforcing bar (1) outside the box body (2). There are bottom plate stiffeners (3) and top plate stiffeners (4) on the bottom plate (7) and top plate (6) of the inner cavity of the box body (2), and the bottom plate stiffeners (3) and top plate stiffeners (4) are cross Cross-shaped stiffeners can also be parallel stiffeners, which can be made into a large-sized box body (2) without increasing the thickness of the bottom plate (7) and top plate (6), thereby obtaining The floor with a large hollow rate can reduce the self-weight of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com