Modular container building connection node

A technology for connecting nodes and containers, applied in the field of connecting nodes of modular container buildings, can solve the problems of low bending stiffness of connecting nodes, difficult installation and alignment, unable to meet the bearing capacity and stiffness of nodes, etc., so as to enhance reliability and tightness. , the effect of increasing the bearing capacity and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

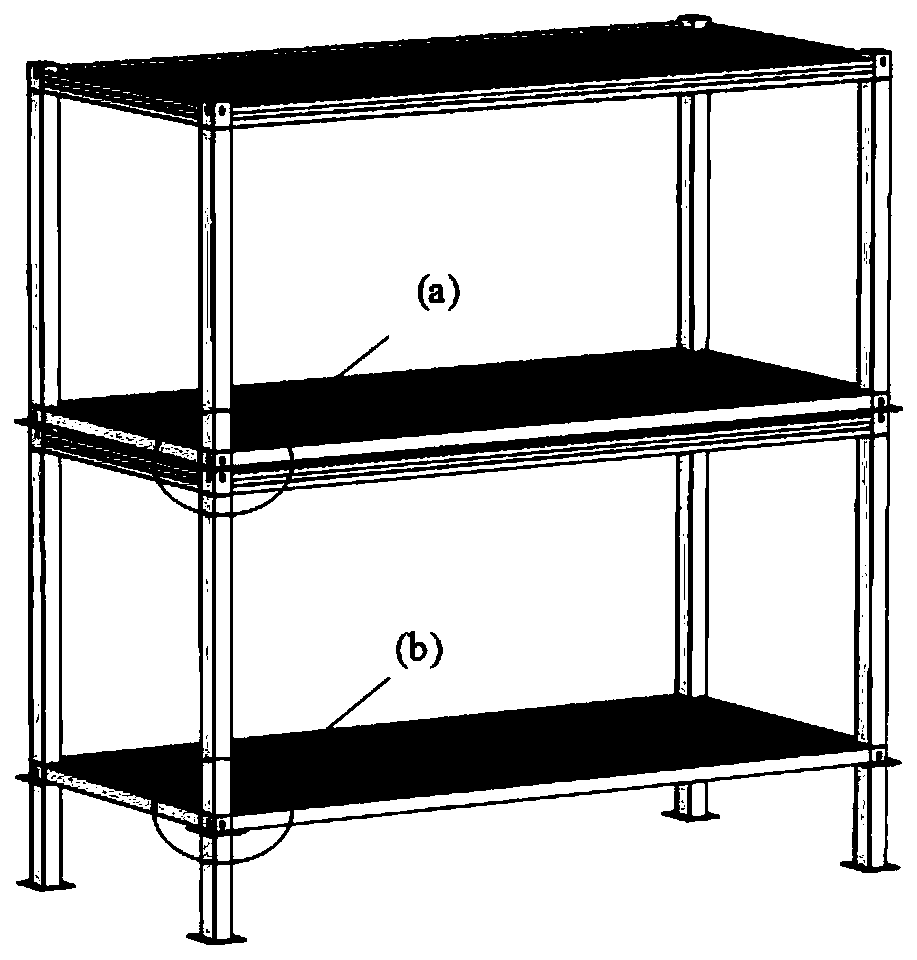

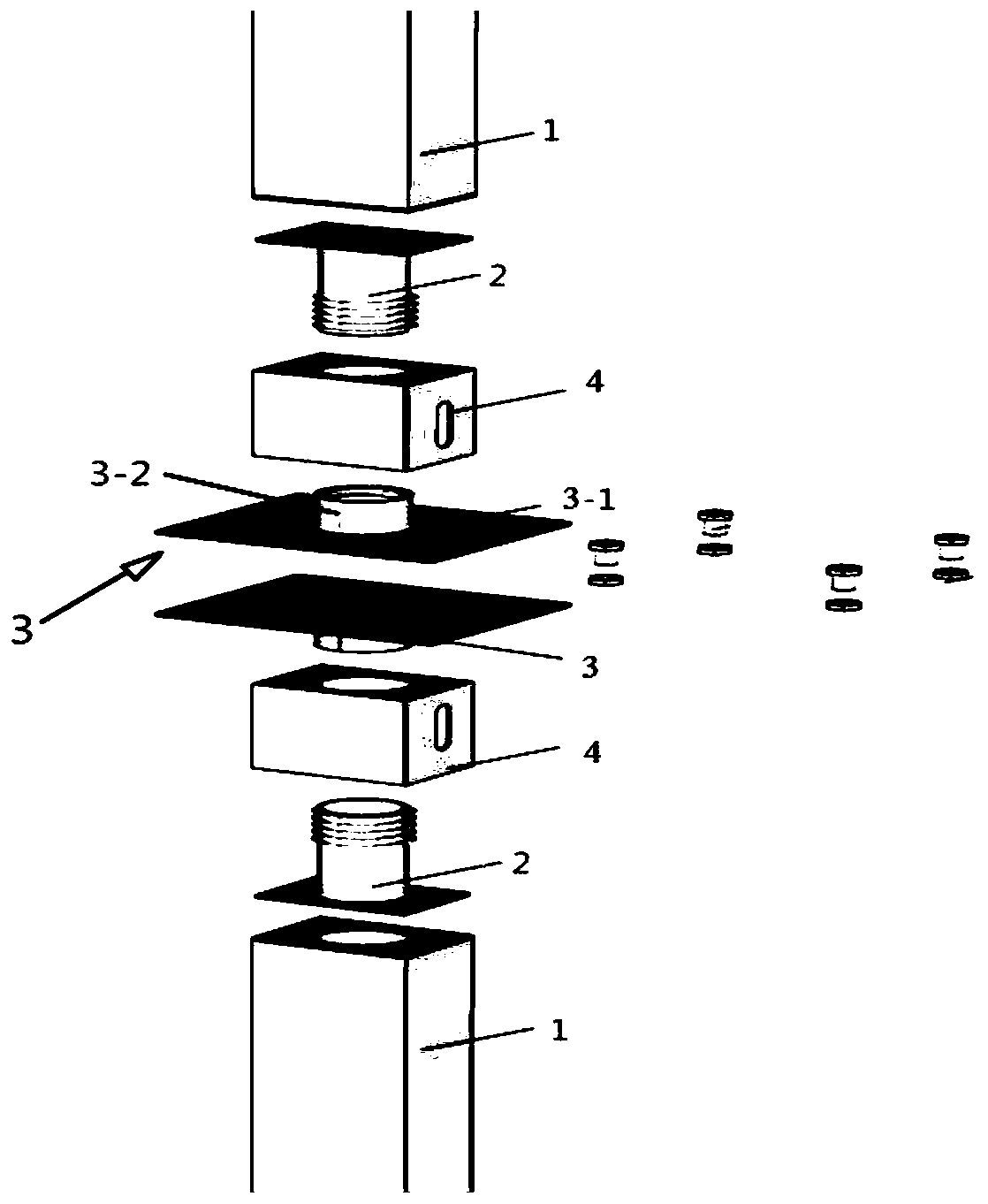

[0022] refer to Figure 1-Figure 2 As shown, a modular container building connection node for connecting the upper and lower container units, figure 1 In node a, the container unit is a cuboid structure composed of four frame beams, four container corner fittings 4 and eight frame columns 1, and the frame columns 1 and the frame beams are composed of cold-formed rectangular tubes , the frame columns 1 and the frame beams are vertically fixed on the container corner fittings 4, and the connecting ends of the adjacent upper and lower two frame columns 1 are fixed with tubular bolts 2, and the tubular bolts 2 The threaded end passes through the container corner fitting 4 adjacent thereto and is threadedly connected with a sleeve 3 , and two adjacent container units up and down are fixedly connected together through two symmetrical sleeves 3 .

[0023] The casing 3 includes an end plate 3-1, on which a cylinder 3-2 is fixed, and the cylinder 3-2 is provided with an internal threa...

Embodiment 2

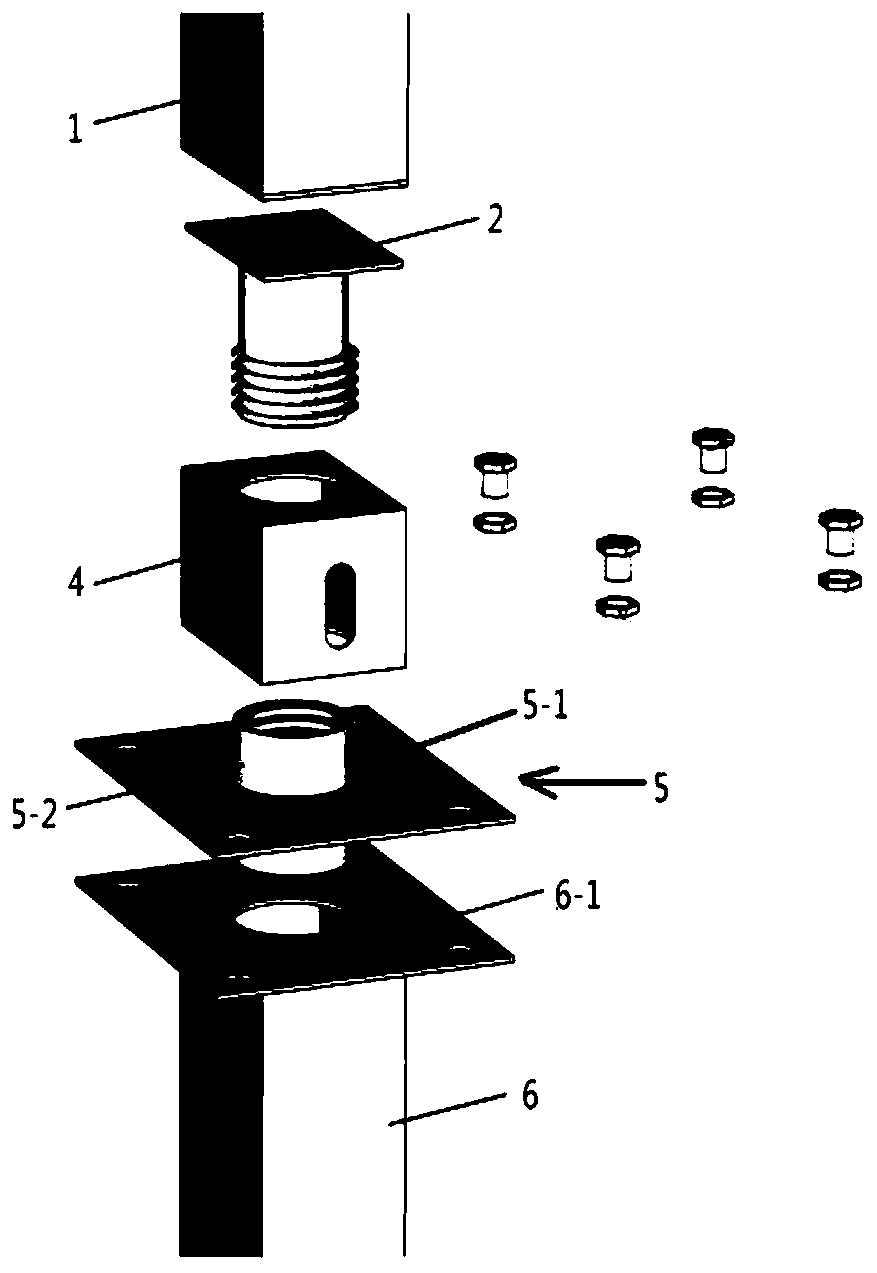

[0035] refer to Figure 1-Figure 3 As shown, a modular container building connection node is used to connect the container unit and the steel pipe pile foundation 6, figure 1 In node b, the container unit is the same as that in Embodiment 1, and the connecting end of the frame column 1 and the steel pipe pile foundation 6 is provided with a tubular bolt 2, and the threaded end of the tubular bolt 2 passes through all adjacent The container corner fitting 4 is threadedly connected with a second casing 5, and the steel pipe pile foundation 6 is provided with a pipe pile end plate 6-1, and the second casing 5 includes a second end plate 5-1, so The second end plate 5-1 is fixed with a second cylinder 5-2 penetrating it, and the second cylinder 5-2 is provided with an internal thread that is threadedly matched with the tubular bolt 2, and the container The unit and the steel pipe pile foundation 6 are fixedly connected together through the second end plate 5-1 and the pipe pile e...

Embodiment 3

[0047] Such as Figure 4 As shown, a modular container building connection node is used to connect the container unit and the concrete pile foundation 7. The container unit is the same as the embodiment 1, and the tubular bolt 2, the container corner fitting 4 and the sleeve are sequentially arranged under the frame column 1. The connection relationship and positional relationship between the pipe 3, the frame column 1, the tubular bolt 2, the container corner fitting 4 and the casing 3 are the same as those in the embodiment 1, and the concrete pile end plate 7-1 is fixed on the concrete pile foundation 7, so that The container unit and the concrete pile foundation 7 are fixedly connected together through the concrete pile end plate 7-1 and the end plate 3-1 of the casing 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com