Both-edge four-angle blade continuous automatic grinding machine tool

A four-angle, blade technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as high labor intensity, low production efficiency, and increased difficulty in product quality control, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment technical scheme of the present invention is further described:

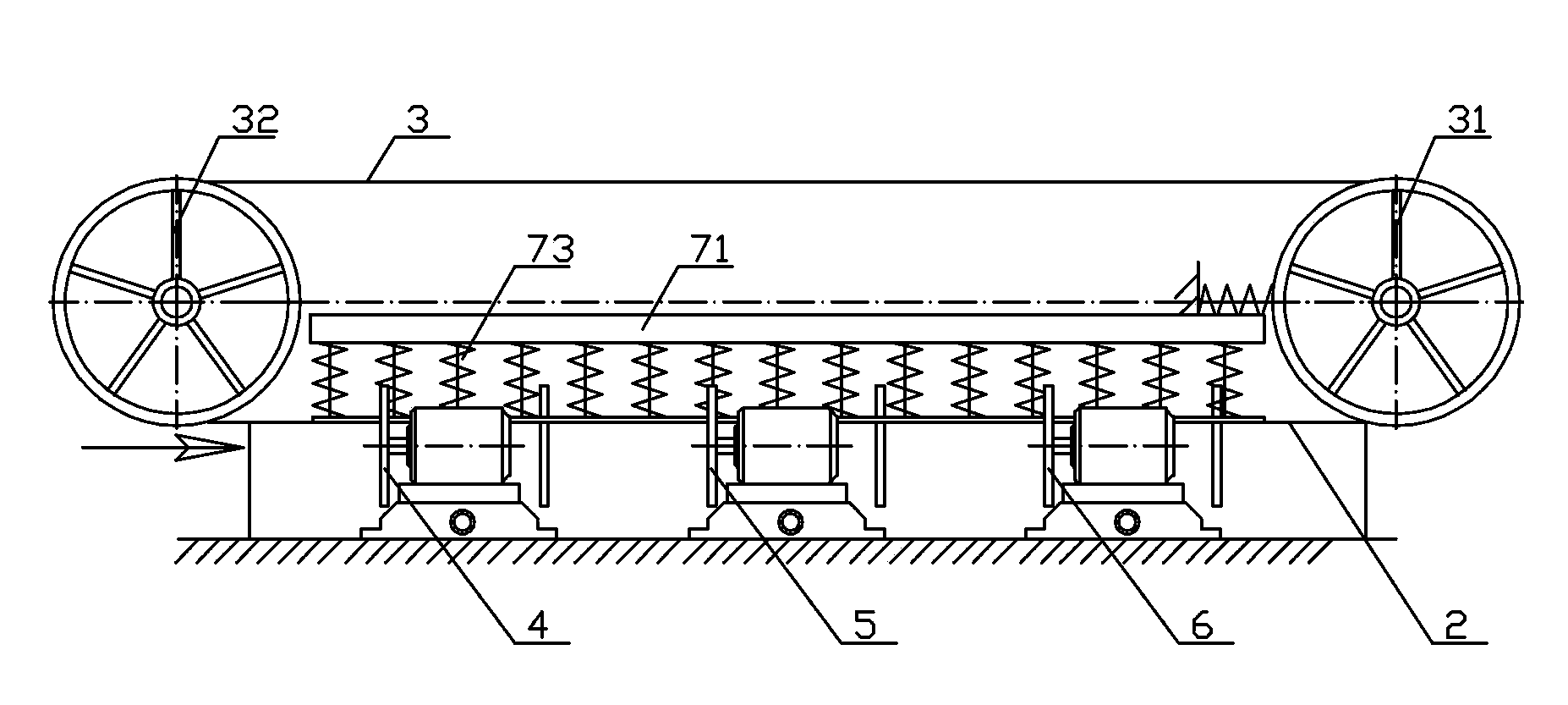

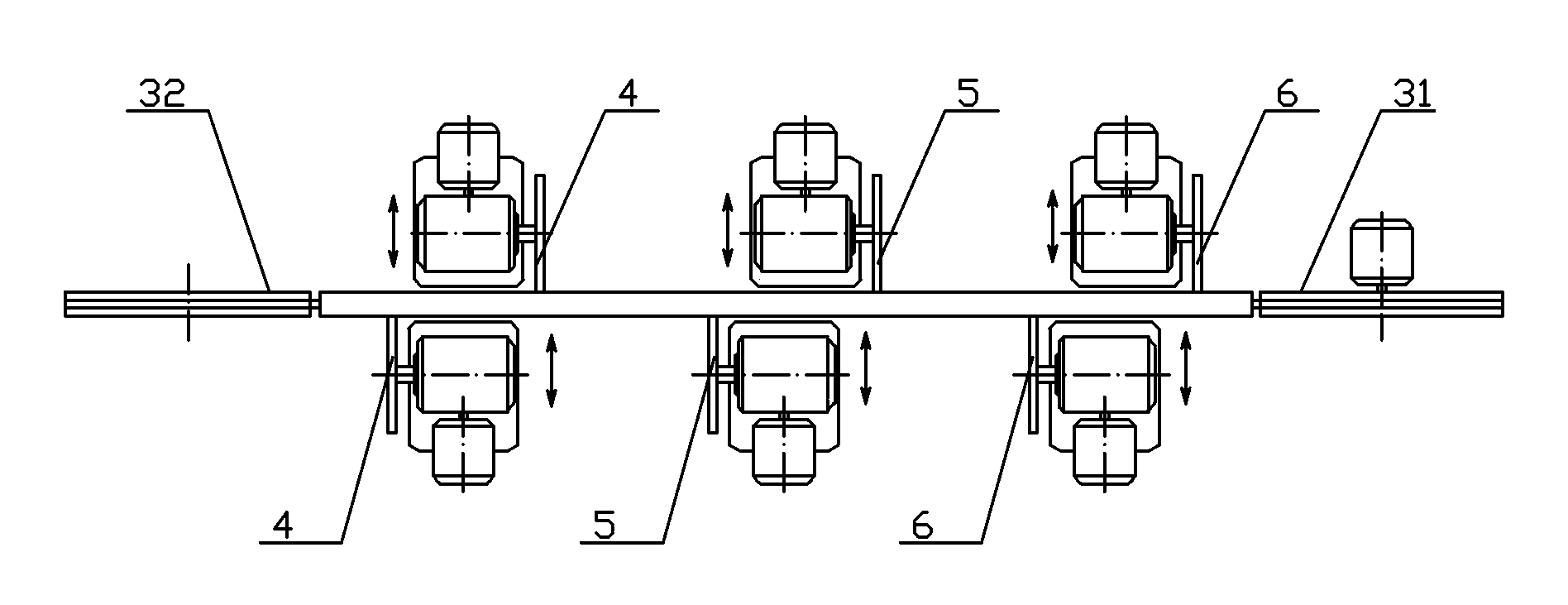

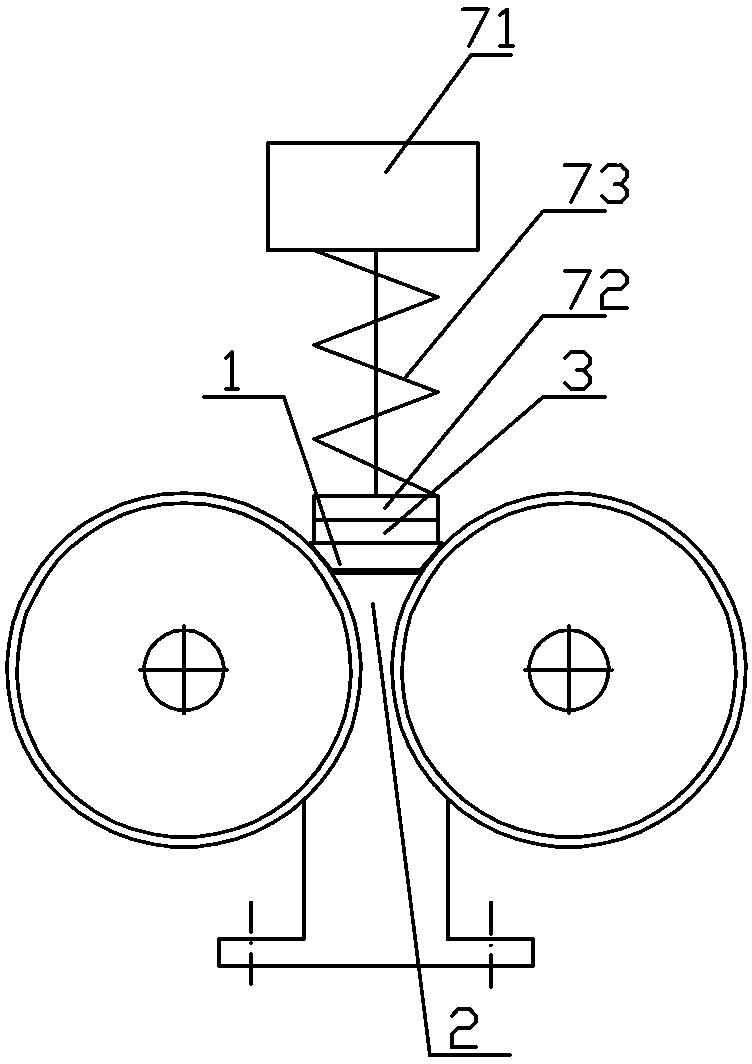

[0017] like figure 1 , figure 2 and, image 3 , Figure 4 and Figure 5 As shown, the present invention provides a double-edged four-angle blade continuous automatic grinding machine, including a support table 2 supporting the blade 1, a conveyor belt 3 for transferring the blade 1 and an elastic pressing device for maintaining the reference of the blade 1, the conveyor belt 3 The outer surface of the blade 1 is provided with a slot for clamping the blade 1, the conveyor belt 3 is tightened by the driving wheel 31 and the driven wheel 32, the driving wheel 31 is connected to the reducer, the width of the conveyor belt 3 is smaller than the width of the blade 1 wide surface, and squeezes Press the middle part of the blade 1, the upper surface of the support table 2 is strip-shaped and parallel to the conveyor belt 3, the width of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com