Double-supply screw locking device

A feeding device and locking screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, and single function, and achieve convenient operation, simple structure, and adjustment accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

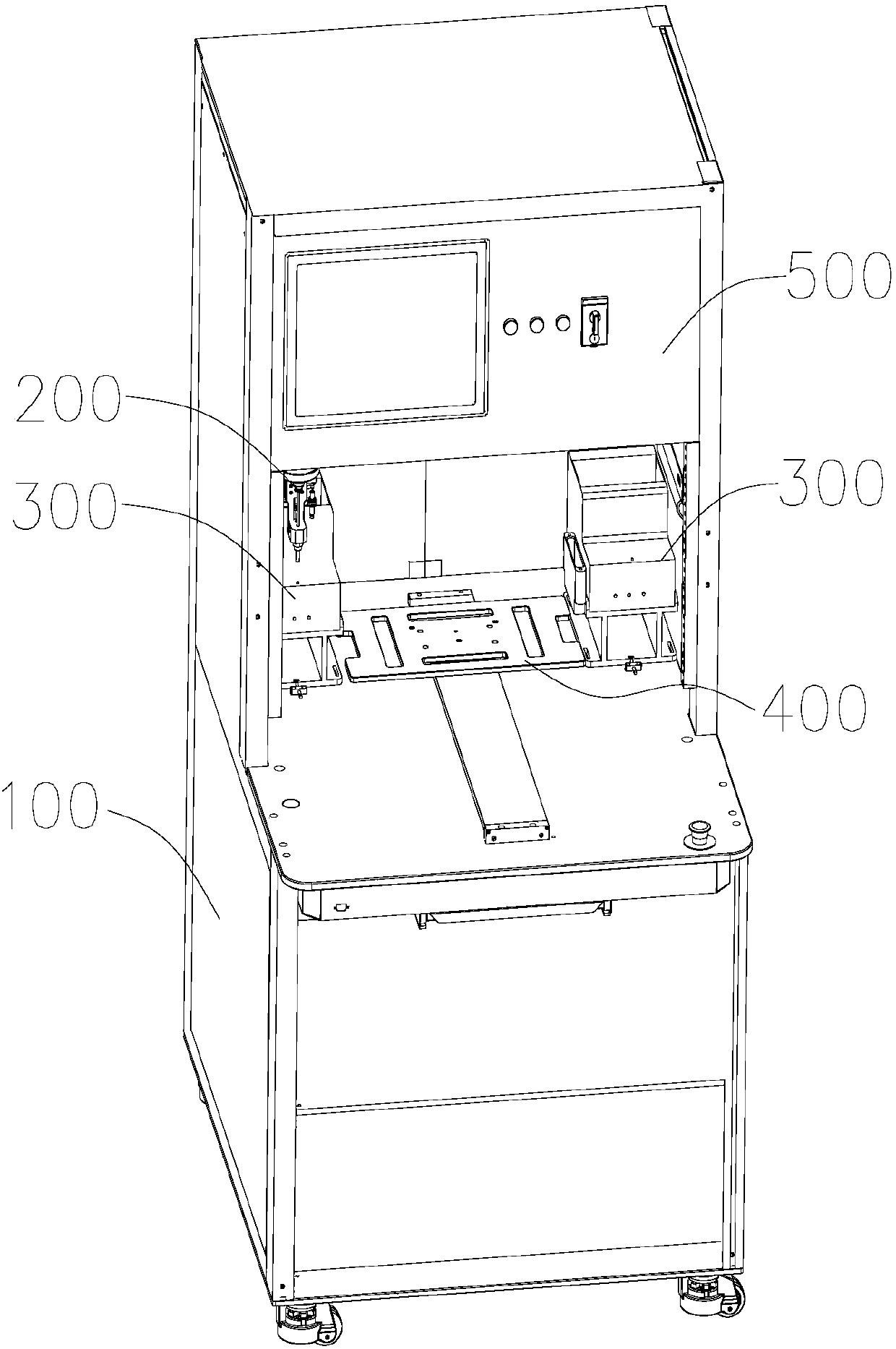

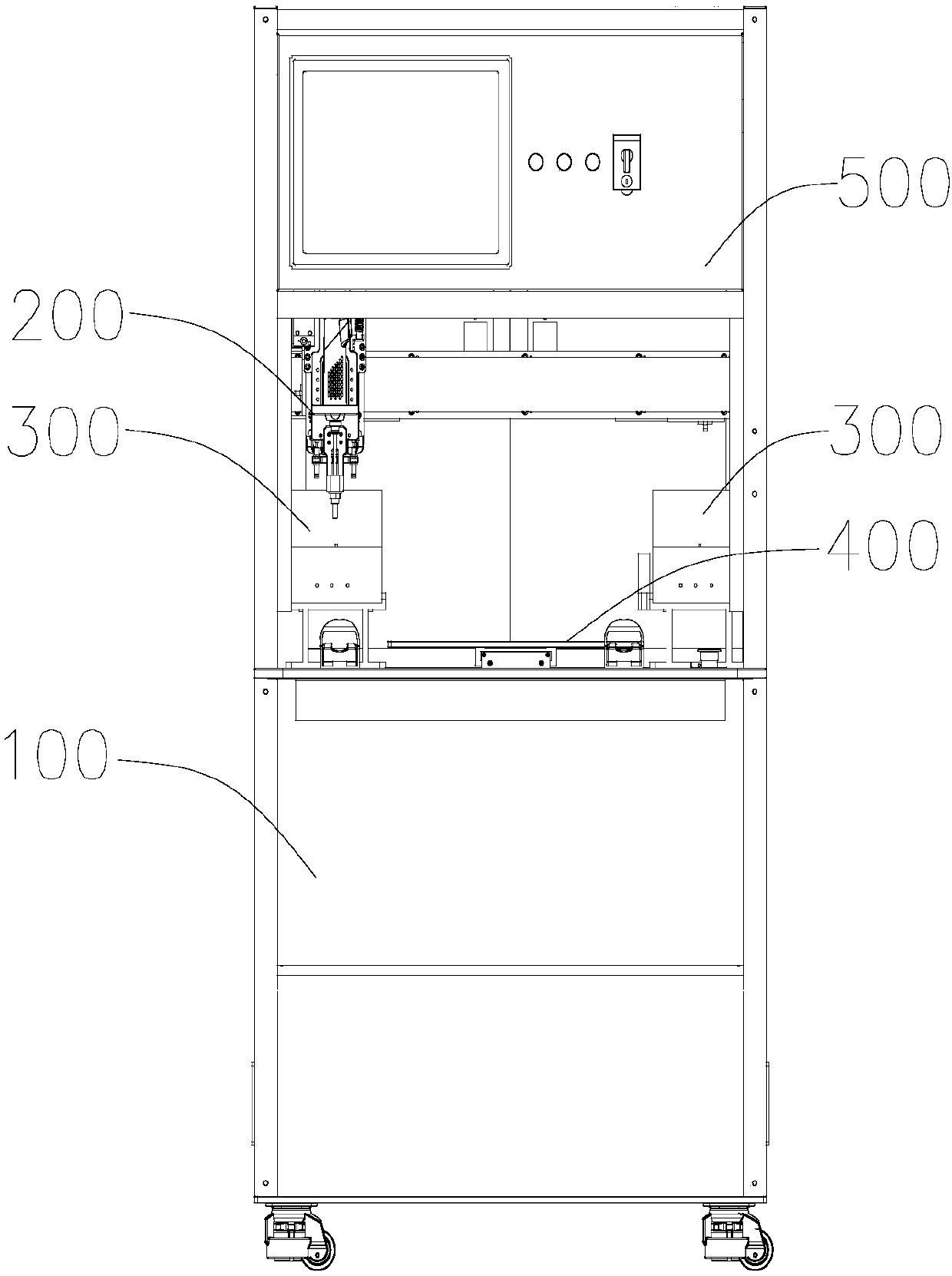

[0018] Such as Figure 1-4 As shown, it is a double-feed screw locking device of the present invention, which includes a mounting platform 100, on which a screw locking machine 200, two feeding devices 300, a fixed jig 400 and a control panel 500, and two feeding devices are installed. 300 is used to provide different types of screws for the screw locking machine 200 , the fixing jig 400 is installed between the two feeding devices 300 , the fixing jig 400 is used for fixing materials, and the control panel 500 is used to control the operation of the screw locking machine 200 .

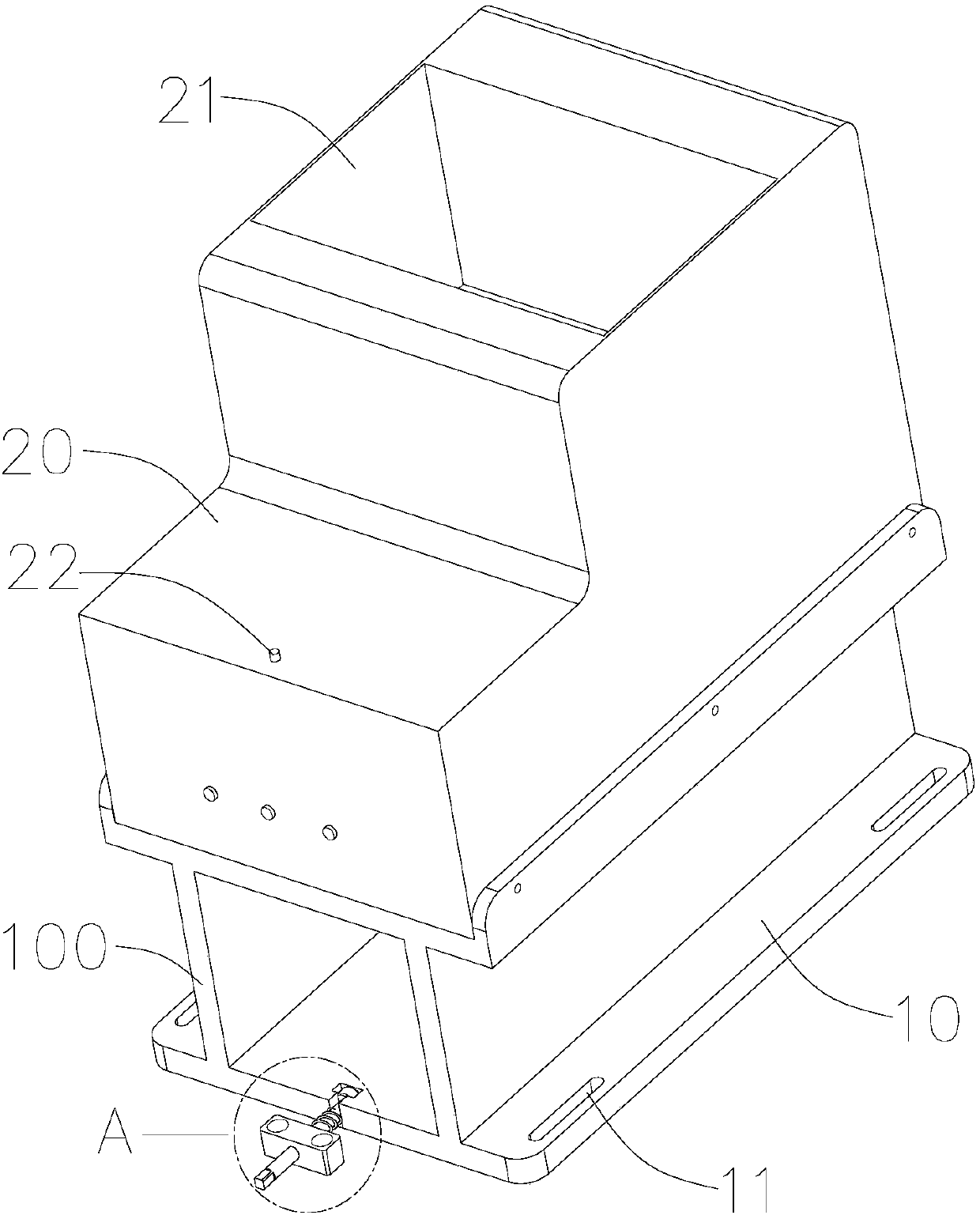

[0019] The feeding device 300 includes a feeding device main body and an adjustment mechanism. A base plate 310 is installed at the bottom of the feeding device main body. The base plate 310 is provided with waist-shaped grooves 311. The number of waist-shaped grooves 311 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com