Closed steel structure of double-cable-coil spoke arch coal shed

A steel structure and cable reel technology, applied in structural elements, building components, building structures, etc., can solve the problems of high clearance requirements and limited space utilization, etc., to reduce use, improve stability, increase rigidity and load bearing force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

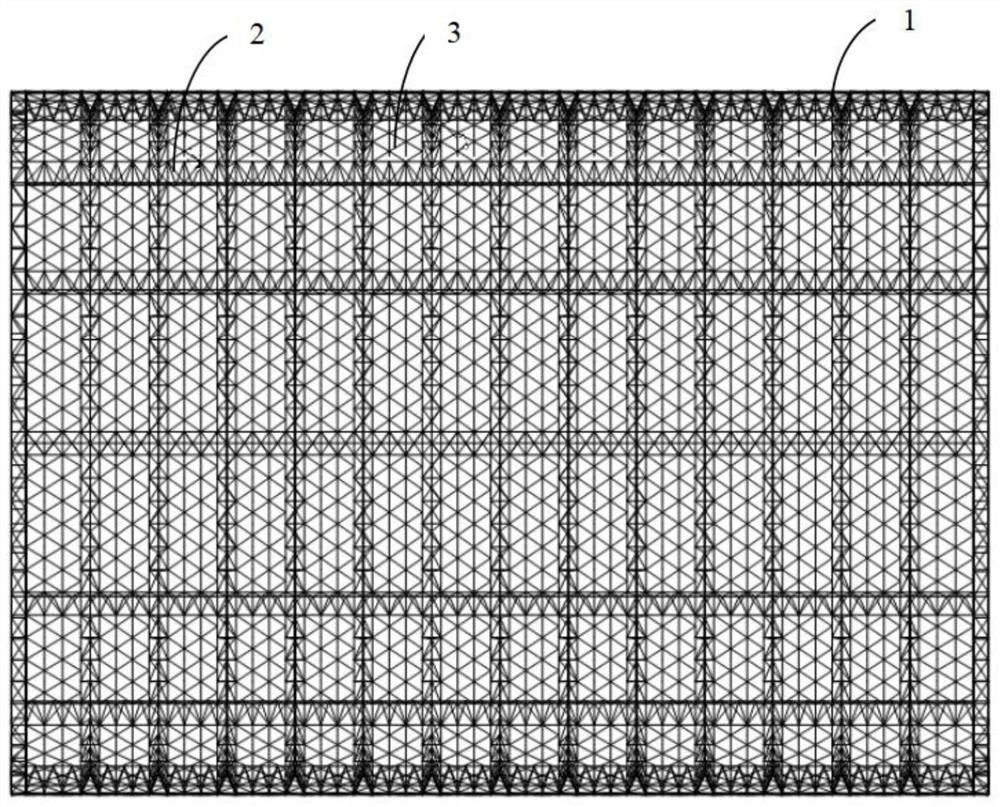

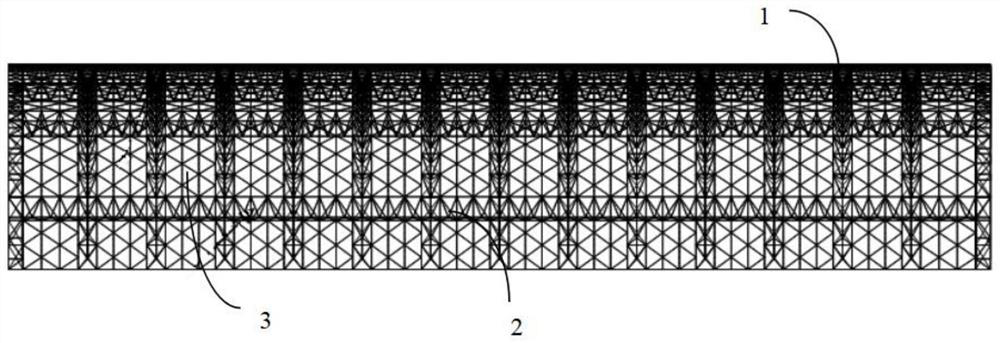

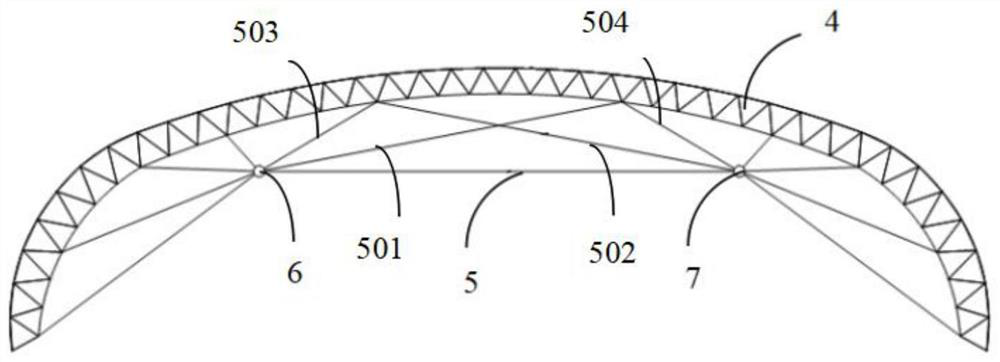

[0026] Such as figure 1 , 2 As shown, a double-cable-drum spoke arch coal shed closed steel structure includes a double-cable-drum spoke arch 1, a longitudinal connecting beam 2 and an arched reticulated shell 3. The arched reticulated shell 3 includes several single reticulated shells connected Between the adjacent double cable drum spoke arch 1 and the longitudinal connecting beam 2. The double cable-drum spoke arch 1 includes a steel arch 4, a prestressed cable 5, a cable tray (a) 6, and a cable tray (b) 7, wherein the steel arch 4 is a circular arch of lattice type. Such as image 3 As shown, the cable tray (a) 6 and the cable tray (b) 7 are symmetrically arranged along the central axis of the steel arch 4, and are connected by prestressed cables 5, wherein the cable tray (a) 6 is connected by 6 prestressed cables 5 is connected to the left part of the steel arch 4, and the cable tray (b) 7 is connected to the right part of the steel arch 4 through 6 prestressed cables ...

Embodiment 2

[0028] Such as figure 1 , 2 As shown, a double-cable-drum spoke arch coal shed closed steel structure includes a double-cable-drum spoke arch 1, a longitudinal connecting beam 2 and an arched reticulated shell 3. The arched reticulated shell 3 includes several single reticulated shells connected Between the adjacent double cable drum spoke arch 1 and the longitudinal connecting beam 2. The double-cable-drum spoke arch 1 includes a steel arch 4, a prestressed cable 5, a cable reel (a) 6, and a cable reel (b) 7, wherein the steel arch 4 is a solid-belly three-core arch. Such as Figure 4 As shown, the cable tray (a) 6 and the cable tray (b) 7 are arranged symmetrically along the central axis of the steel arch 4 and are connected by prestressed cables 5, wherein the cable tray (a) 6 is connected by five prestressed cables 5 is connected to the left part of the steel arch 4, and the cable tray (b) 7 is connected to the right part of the steel arch 4 through five prestressed cab...

Embodiment 3

[0030] Such as figure 1 , 2 As shown, a double-cable-drum spoke arch coal shed closed steel structure includes a double-cable-drum spoke arch 1, a longitudinal connecting beam 2 and an arched reticulated shell 3. The arched reticulated shell 3 includes several single reticulated shells connected Between the adjacent double cable drum spoke arch 1 and the longitudinal connecting beam 2. The double-cable-drum spoke arch 1 includes a steel arch 4, a prestressed cable 5, a cable reel (a) 6, and a cable reel (b) 7, wherein the steel arch 4 is a solid-belly centered arch. Such as Figure 5 As shown, the cable tray (a) 6 and the cable tray (b) 7 are arranged symmetrically along the central axis of the steel arch 4 and are connected by prestressed cables 5, wherein the cable tray (a) 6 is connected by three prestressed cables 5 is connected to the left part of the steel arch 4, and the cable tray (b) 7 is connected to the right part of the steel arch 4 through three prestressed cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com