Fabricated outer ring plate beam column joint

A technology of slab-beam-column and outer-ring slabs, which is applied in the direction of construction and building construction, can solve the problems of brittle fracture, reduced construction efficiency, and large residual stress, so as to improve rigidity and bearing capacity, avoid welding operations, The effect of reducing quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

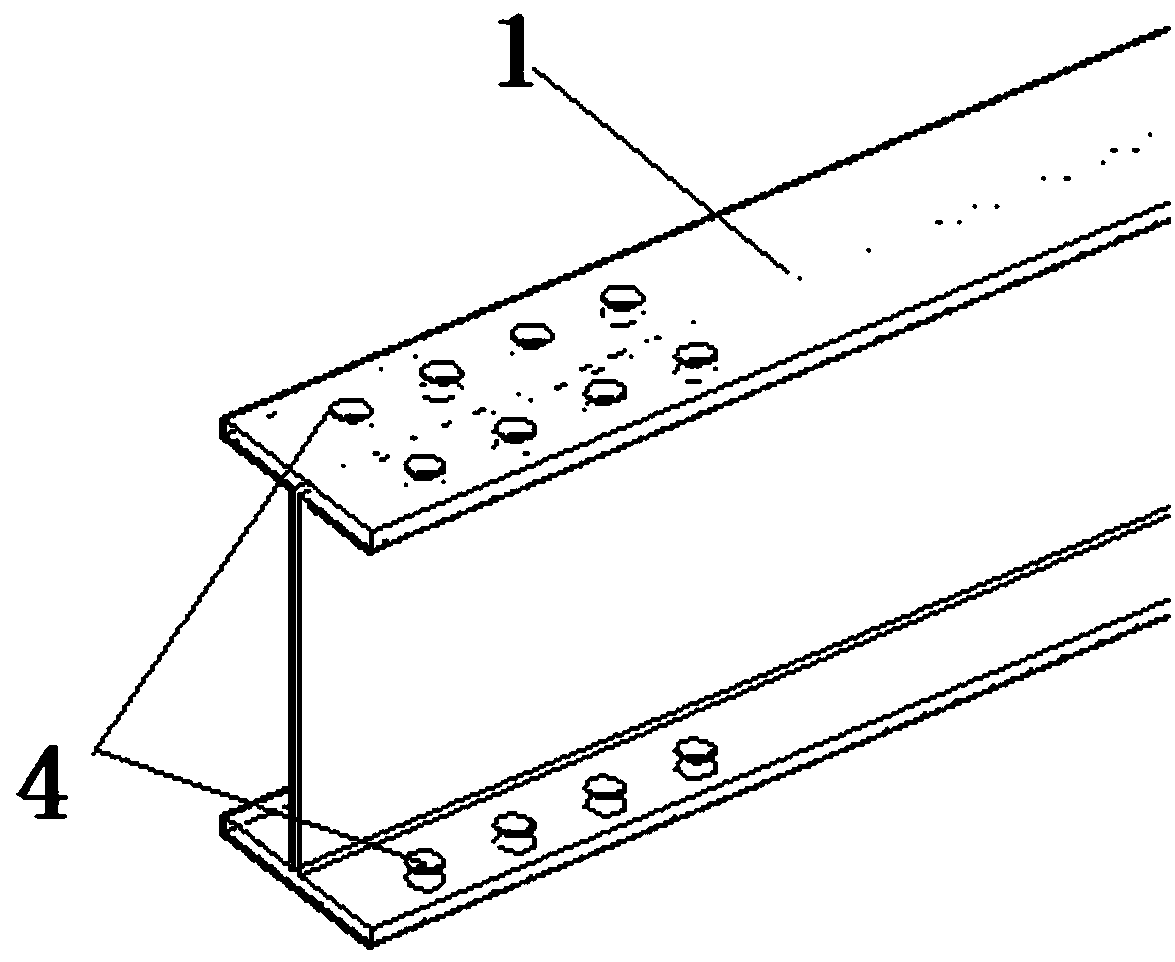

[0026] The present invention will be further described below in conjunction with accompanying drawing.

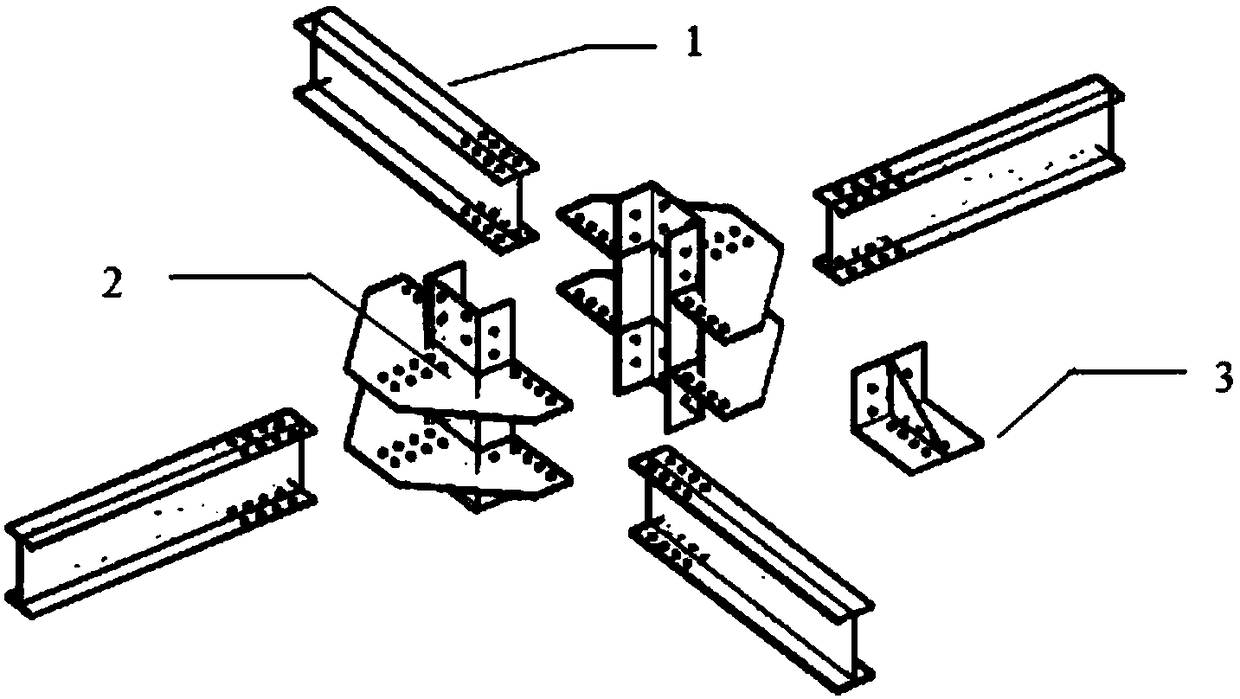

[0027] refer to figure 1 As shown, an assembled outer ring plate beam-column joint includes a structural column, and the front and rear of the structural column are respectively connected to the outer ring plate channel steel connector 2 by bolts;

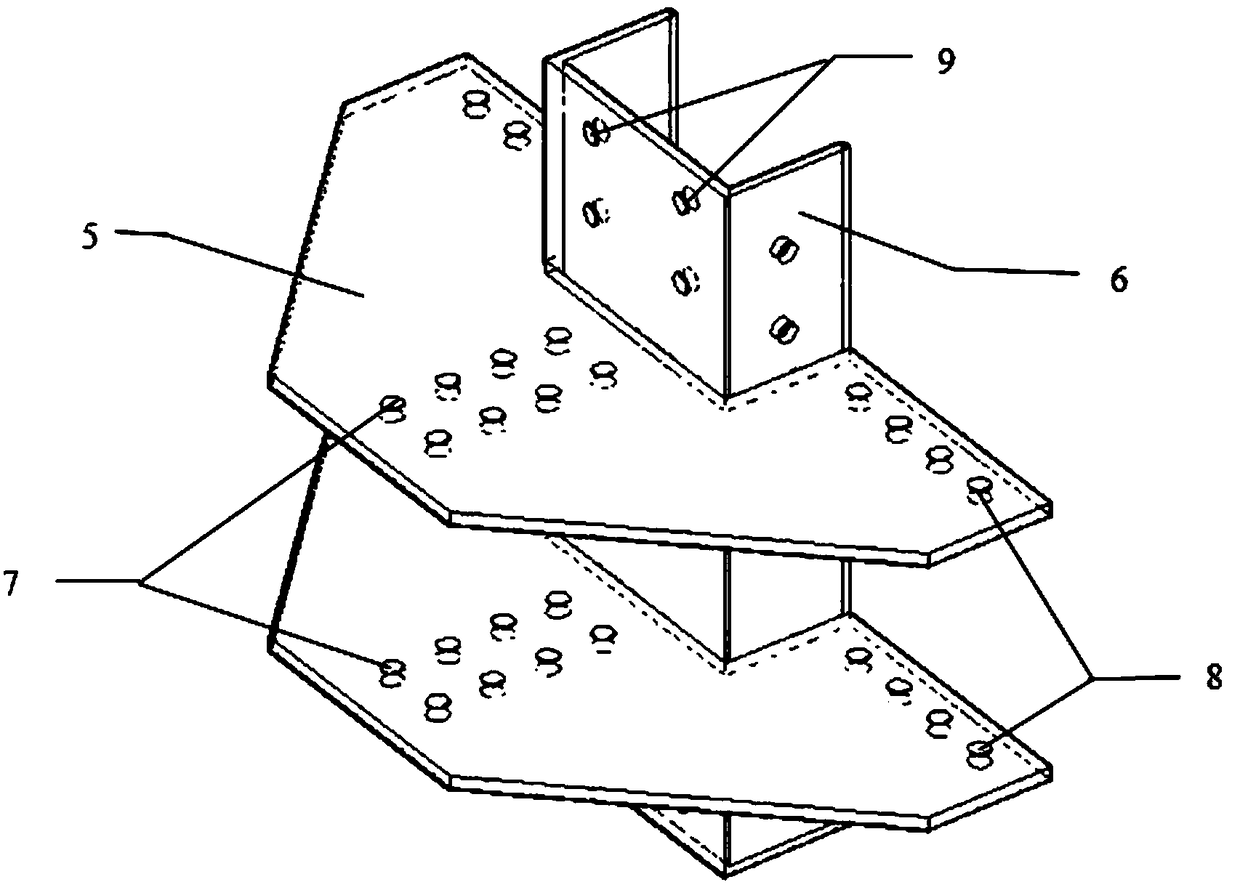

[0028] refer to image 3 As shown, the channel steel connector 2 of the outer ring plate includes a channel steel 6, the channel steel bolt hole 9 is arranged on the channel steel 6, and the channel steel bolt hole 9 cooperates with the structural column bolt hole on the structural column; the channel steel 6 The outer ring plate 5 arranged in parallel is welded on the top, the bottom edge of the outer ring plate 5 is provided with a single row of holes 8 in the outer ring plate, and the middle part of the outer ring plate 5 is provided with a double row of holes 7 in the outer ring plate;

[0029] refer to figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com