Multi-layer coated carbon fiber reinforcement fireproof heat insulation system and construction method thereof

A technology of carbon fiber reinforcement and carbon coating, which is applied in building maintenance, insulation improvement, construction, etc. It can solve the problems of lack of operability in regulations and difficulty in ensuring the safety of fire protection requirements, and achieve excellent fire and heat insulation effects and long reinforcement effects. Long-lasting effect and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment describes the present invention in detail by taking the reinforcement, fire prevention and heat insulation of steel pipe components under pressure in industrial high-temperature environments as an example.

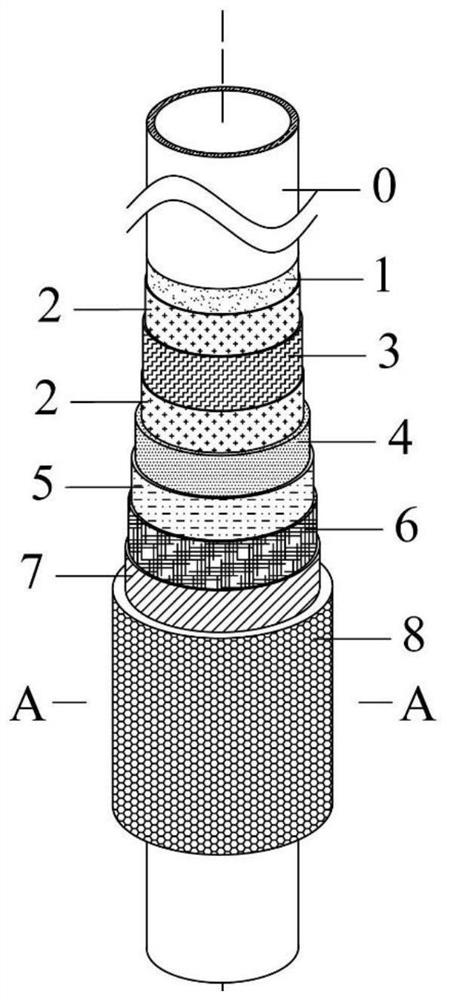

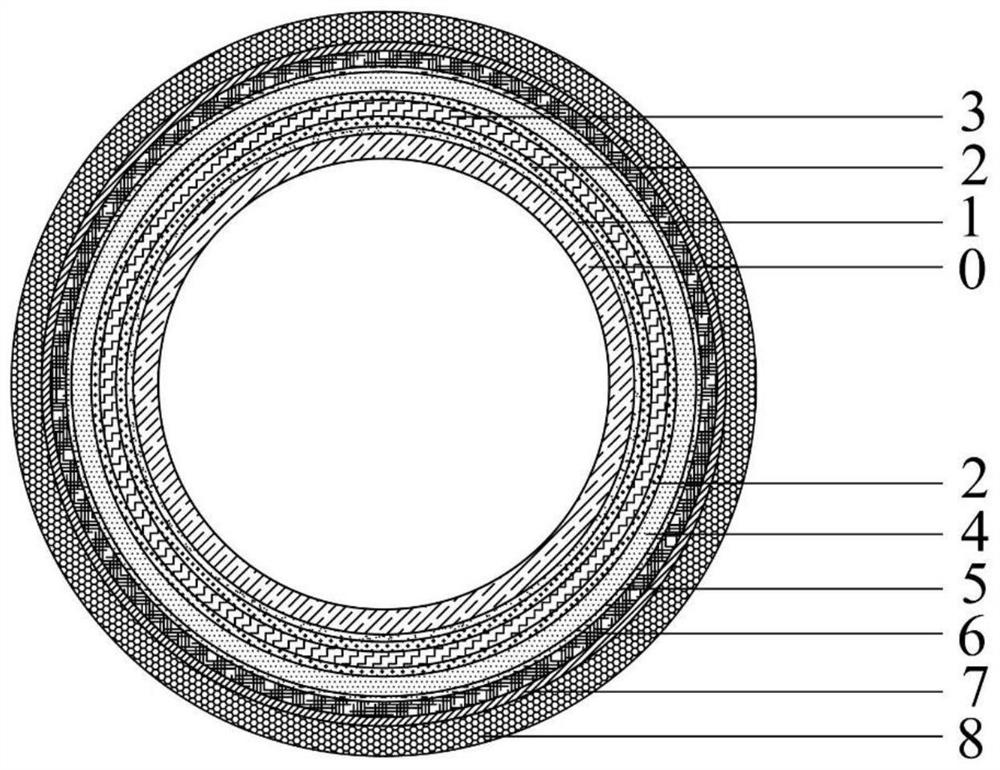

[0070] Multi-layer clad carbon fiber reinforced fireproof and heat insulation system, including carbon fiber reinforced layer, sealed heat insulation layer, and flame retardant layer. The carbon fiber reinforcement layer includes structural primer 1, carbon fiber flame-retardant impregnating glue 2, and carbon fiber cloth 3; the sealing and heat-insulating layer includes heat-insulating paste 4, film-forming agent 5, and airgel felt 6; the flame-retardant layer includes self-adhesive fireproof tape 7 And thick fireproof coating8.

[0071] Sticking carbon fiber cloth on the surface of steel pipe components can effectively improve the bearing capacity of components, the sealing and heat insulation layer can effectively block moisture intrusion and redu...

Embodiment 2

[0085] This example is set up to verify the reinforcement effect of the reinforced fireproof and heat insulation system of the present invention.

[0086] According to the method in Example 1, one steel pipe member was reinforced, fireproof and heat-insulated, and the other steel pipe member was used as a control group. According to the relevant national standards, the above two steel pipe members were subjected to axial compression tests, and the bearing performance results are shown in Table 1. It can be seen that the ultimate bearing capacity of the steel pipe member can be effectively increased by adopting the method for strengthening fire prevention and heat insulation of the present invention, and the increase range is about 12%.

Embodiment 3

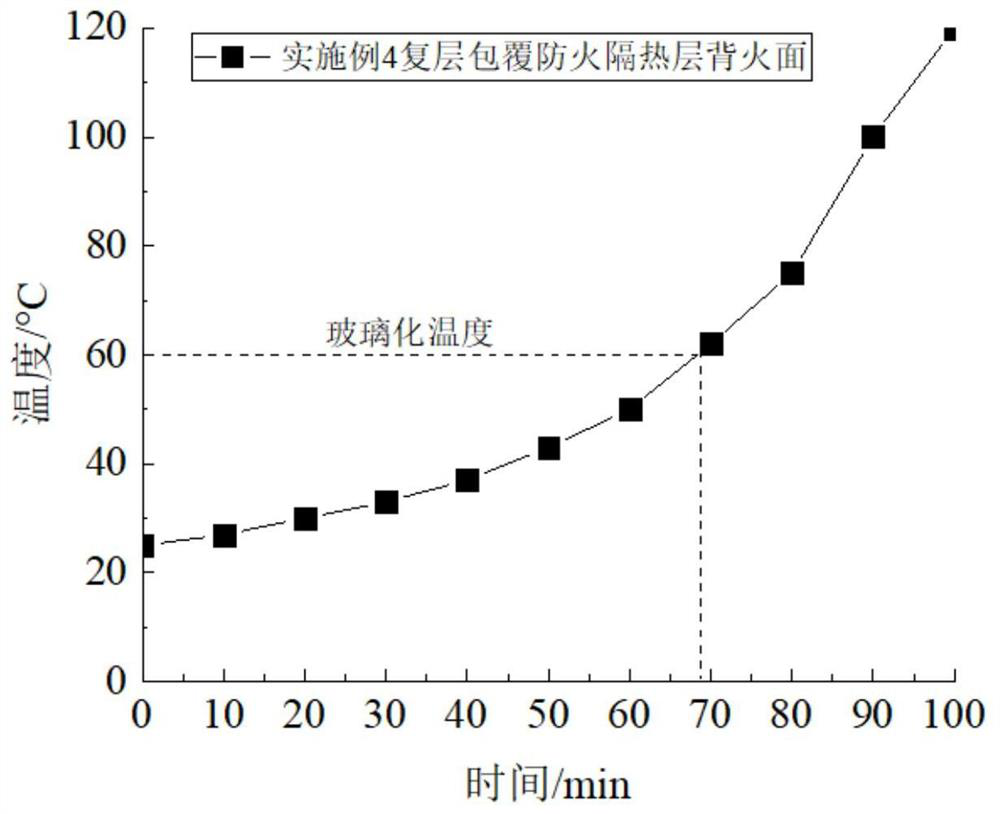

[0090] This example is set up to verify the fire and heat insulation effect of the reinforced fire and heat insulation system of the present invention. According to the method in Example 2, the two steel pipe members are reinforced, fire-resistant and heat-insulated. In accordance with the relevant standards, a simulated fire combustion test was carried out on one of the components. Table 2 shows the test results. image 3 It is the temperature rise-time curve of the unfired surface of the double-layer cladding fireproof and heat insulation layer under the standard temperature rise. Depend on image 3 It can be seen that the flame retardant layer and the sealing and heat insulation layer played a good role in heat insulation during the whole test process, and the time for the impregnated resin to reach the glass transition temperature was 60 to 70 minutes. It can be seen from Table 2 that under the protection of the flame-retardant layer, its overall combustion performance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com