Quantitative pushing device for air valve spring gaskets on engine cylinder cover

An engine cylinder head and valve spring technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to accurately remove gaskets, missing installation, and difficult to find, so as to improve assembly quality and assembly speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

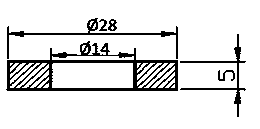

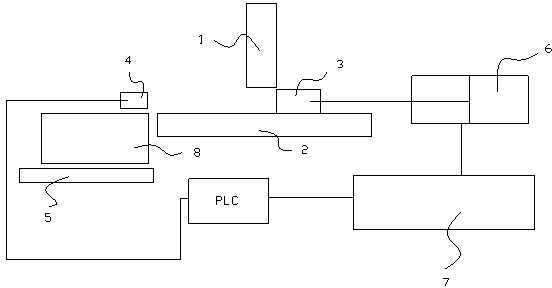

[0015] Such as figure 2 , the engine cylinder head valve spring gasket quantitative pushing device of the present invention comprises a vertically placed barrel 1, the diameter of the barrel 1 matches the diameter of the spring washer, the bottom of the barrel 1 is a base plate 2, and the lower end of the barrel 1 is in contact with the spring washer. Between the substrates 2 is a pusher block 3, the height of the pusher block 3 is greater than N-1 times the thickness of the spring washer and less than N times the thickness of the spring washer, N is the quantity of the spring washer pushed each time, and the barrel The distance between the lower end of 1 and the substrate 2 is greater than N times the thickness of the spring washer and less than N+1 times the thickness of the spring washer, and the pushing block 3 can reciprocate horizontally between the barrel 1 and the substrate 2 .

[0016] The present invention also includes proximity switch 4, and proximity switch 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com