Device for measuring test hole compression deformation

A technology of extrusion deformation and measuring holes, which is applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of large measurement error, low installation efficiency, and adhesive failure, etc. Ergonomic, reduced measurement error, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

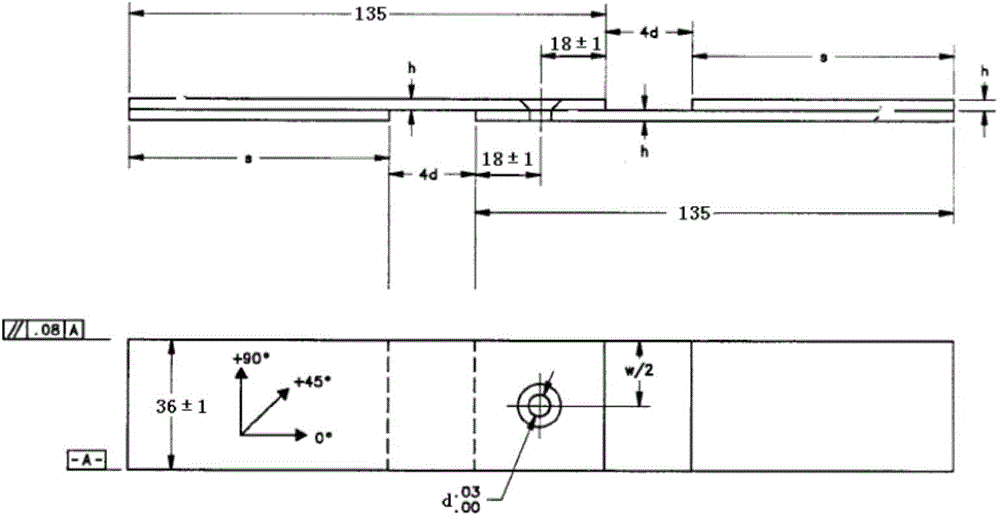

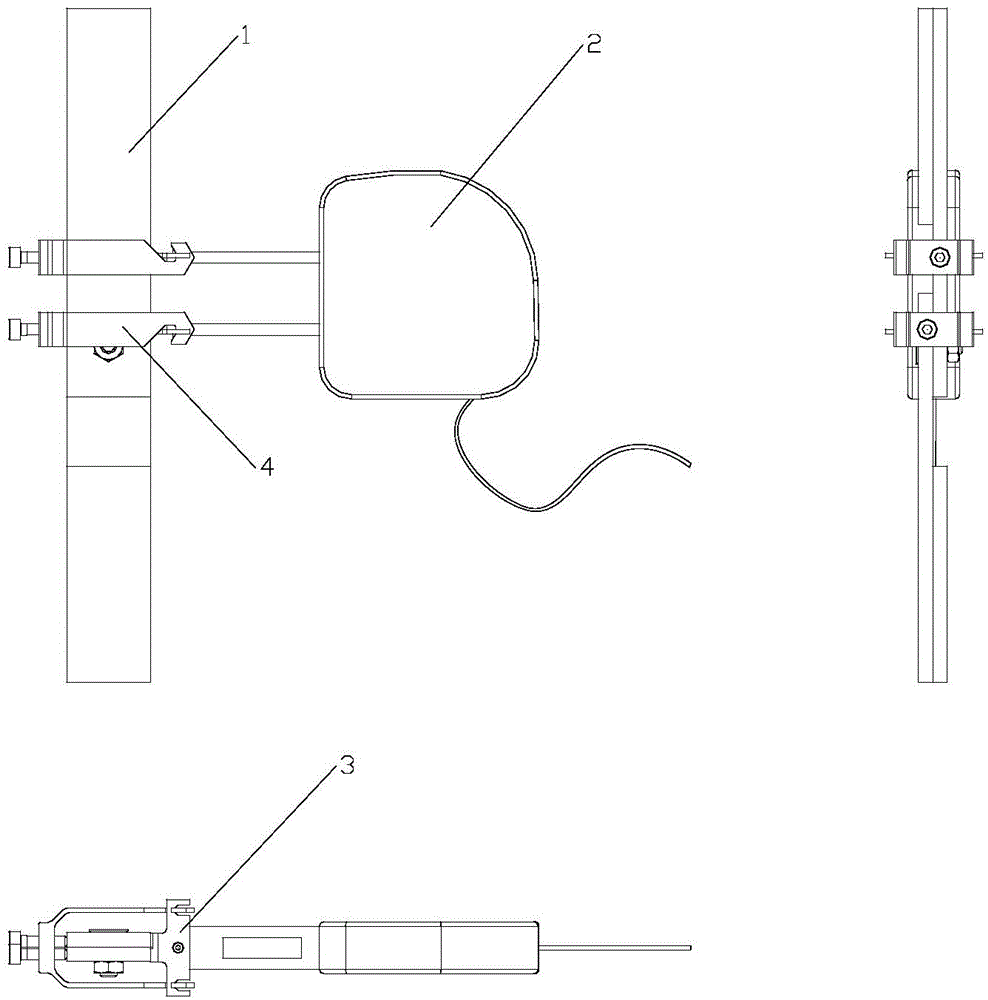

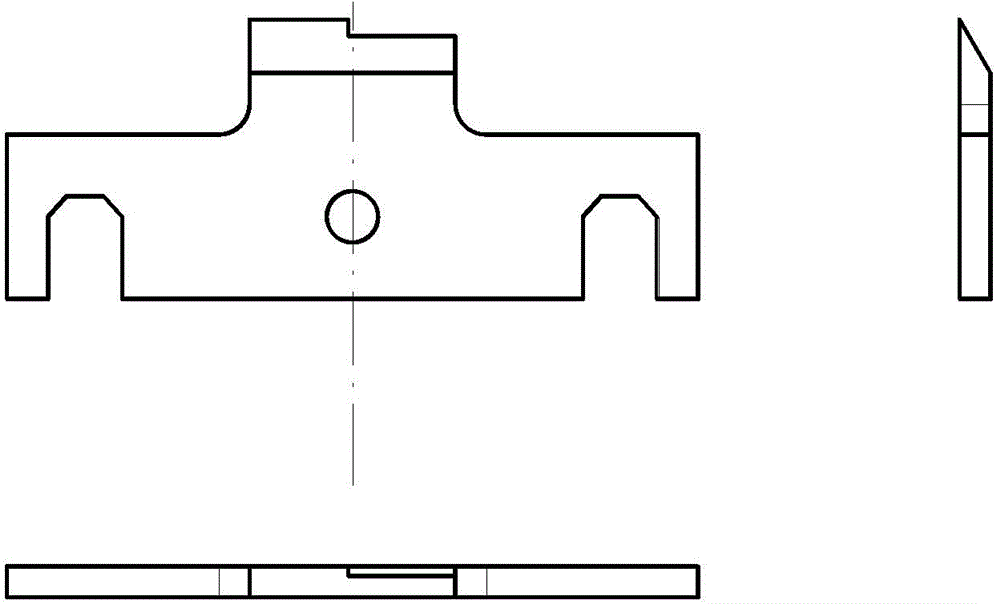

[0022] Such as figure 2 As shown, the hole squeeze deformation measurement system includes a test piece 1, an extensometer 2, two identical asymmetric extensometer knife edges 3, and two extensometer fixing devices 4. Since it is necessary to measure the relative deformation of the two overlapping laminates to determine the extrusion deformation of the hole, and the sides of the two overlapping laminates are coplanar and not coaxial, the present invention designs an asymmetric extensometer knife edge . figure 2 Three views of the knife edge of the asymmetric extensometer, where the axis in the front view coincides with the center line of the extensometer arm. When the knife edge is used to measure the deformation of the mechanical connection test hole, the axis is also coplanar with the lap surface of the test piece. The asymmetric extensometer is actually obtained by cutting the blade of the symmetrical extensometer blade in half along the midline, and then continuing to grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com