Series electromagnetic-elastic foil combined bearing

An elastic foil, hybrid bearing technology, applied in magnetic bearings, rotating bearings, bearings, etc., can solve the problems of rotor floating, large wear, low bearing capacity, etc., to reduce the total volume, facilitate processing, occupy small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

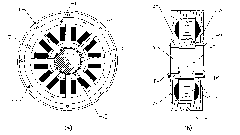

[0022] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The invention mainly aims at the basic requirements of not increasing the axial length of the bearing and not increasing the air gap between the electromagnetic bearing and the rotor journal, and designs the structure for installing the elastic foil bearing.

[0024] refer to figure 1 , an overall structure of an electromagnetic-elastic foil hybrid bearing arranged in series, including a bearing seat 17, an electromagnetic bearing 1 is arranged in the bearing seat 17, a magnetic pole 6 is arranged on the electromagnetic bearing 1, and a coil 7 is wound on the magnetic pole 6, and the electromagnetic bearing 1 A left end cover 2 and a right end cover 3 for pressing the magnetic pole 6 are arranged in the axial direction, and two elastic foil bearings 5 are nested between the left end cover 2 and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com