Overhanging wall cap building structure system for shear wall barrel of high-rise building

A technology for high-rise buildings and building structures, which is applied in the direction of building structures and buildings, can solve problems such as limited stiffness and bearing capacity, difficulty in making up for stiffness defects, and increasing the cost of building structures, so as to improve stress, increase stiffness, and increase resistance. The effect of shear ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

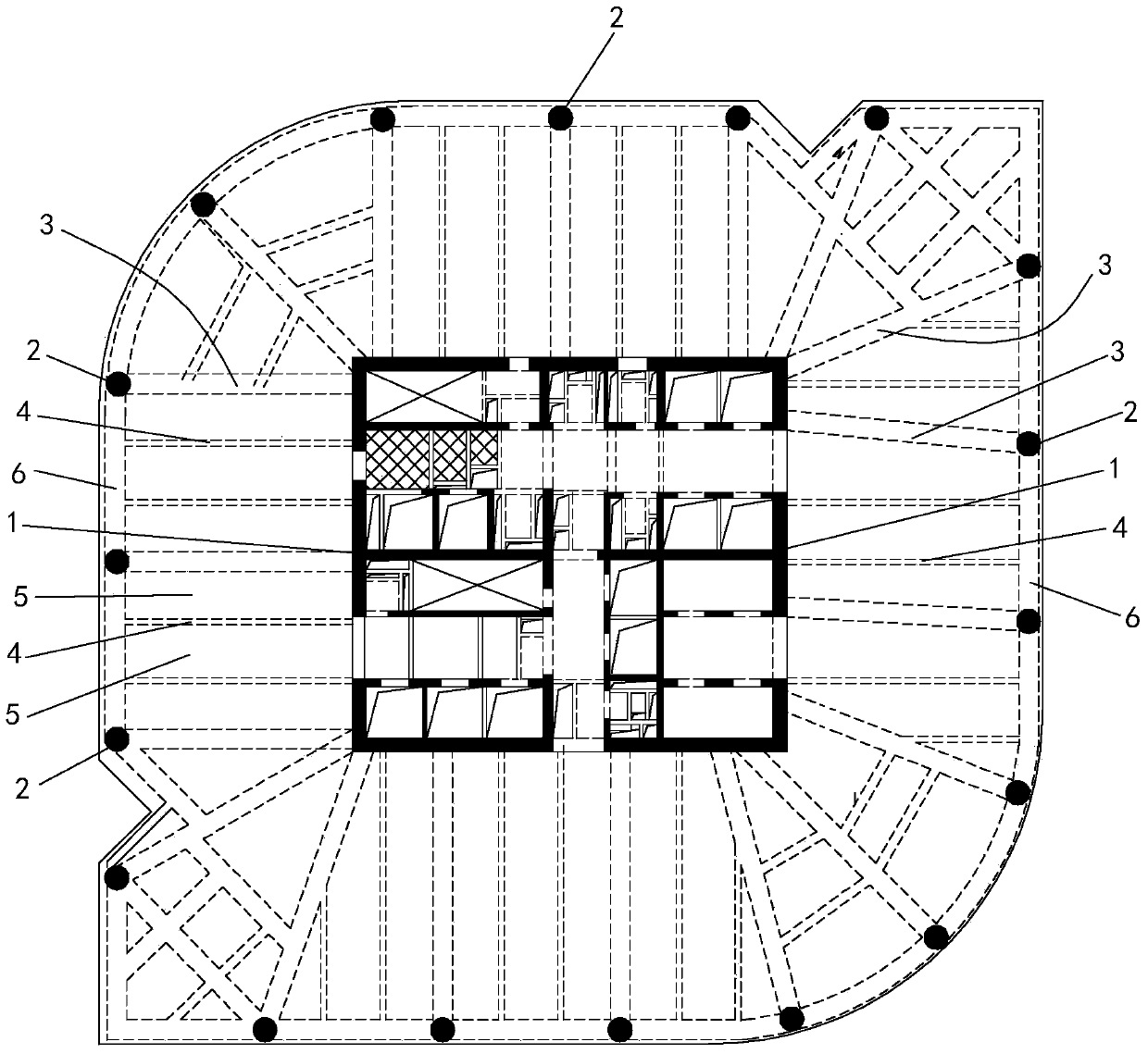

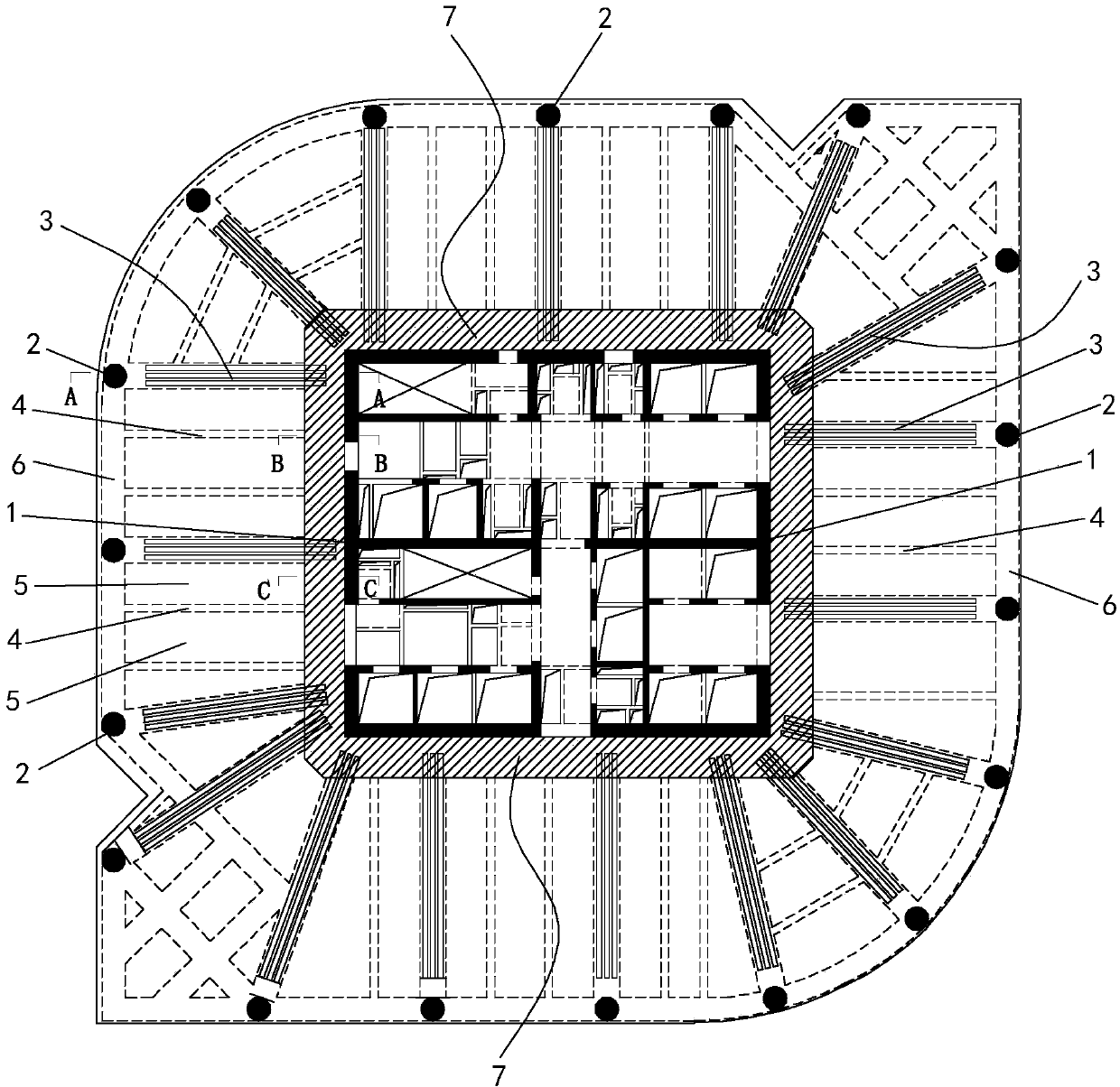

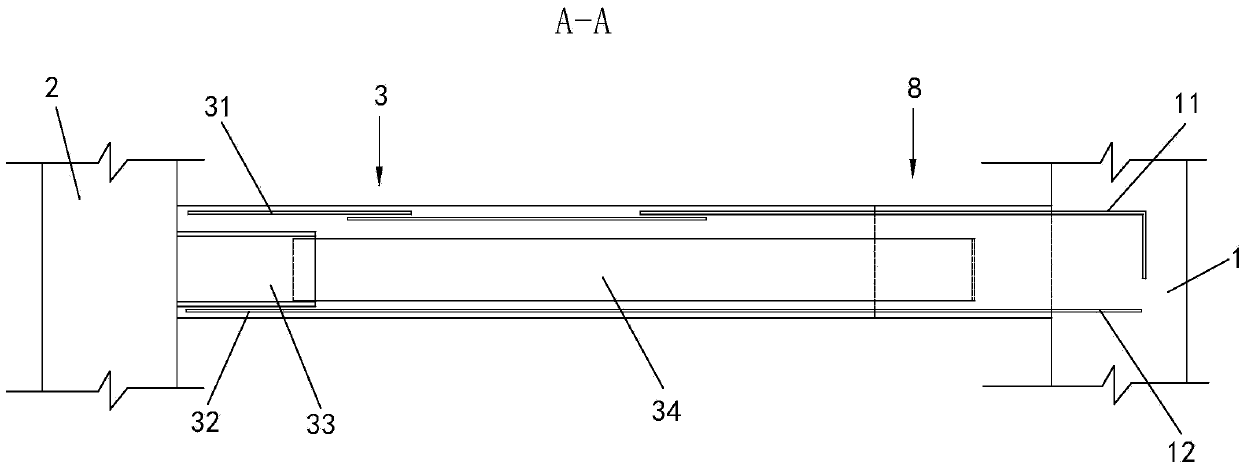

[0038] Such as Figure 2 to Figure 7 Shown is a high-rise building shear wall cylinder external extension wall cap building structure system, which is composed of a shear wall cylinder 1, a frame beam 3, a secondary beam 4, a frame column 2, an outer ring frame beam 6 and a floor slab 5. The force wall cylinder 1 is arranged vertically and is located at the center of the high-rise building. The frame column 2 is a reinforced concrete column arranged vertically. The frame column 2 is located on the periphery of the shear wall cylinder 1. Between adjacent frame columns 2 The outer ring frame beam 6 is built, and the frame beam 3 and the secondary beam 4 are horizontally erected beams, wherein the two ends of the frame beam 3 are respectively erected on the frame column 2 and the shear wall cylinder 1, and the secondary beam 4 is respectively erected On the frame beam 6 of the outer ring and the shear wall cylinder 1, the frame beam 3 and the secondary beam 4 are distributed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com