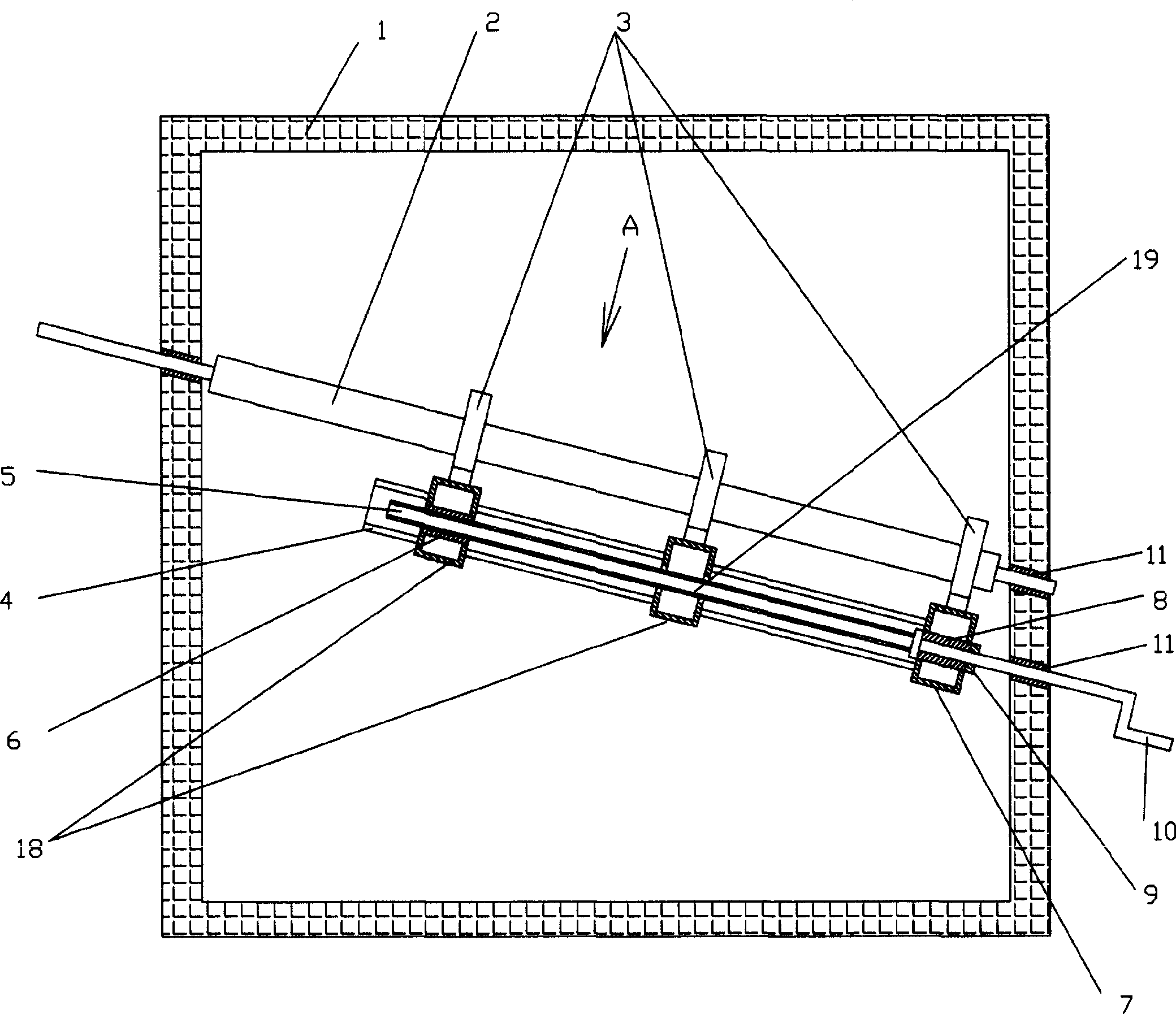

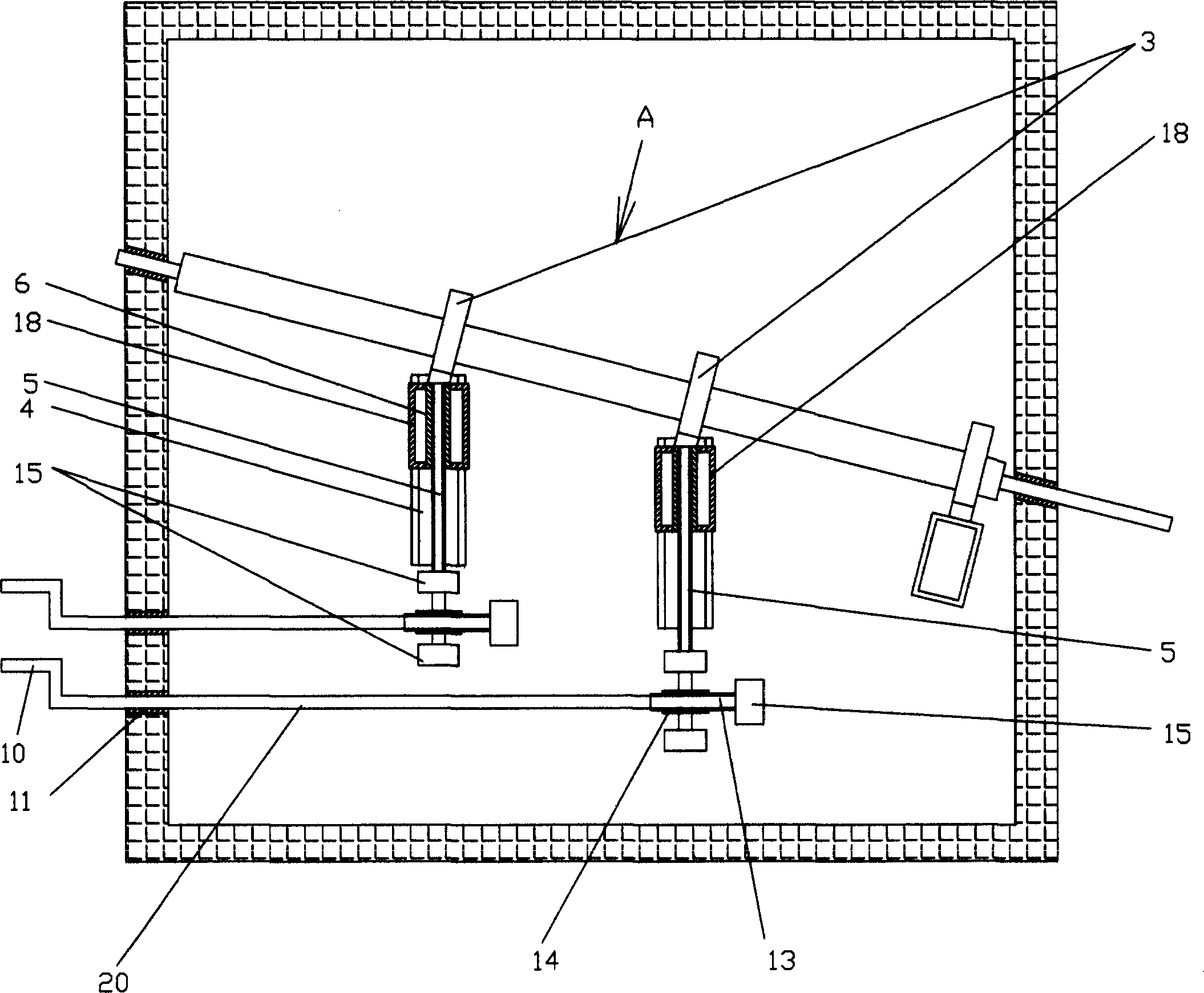

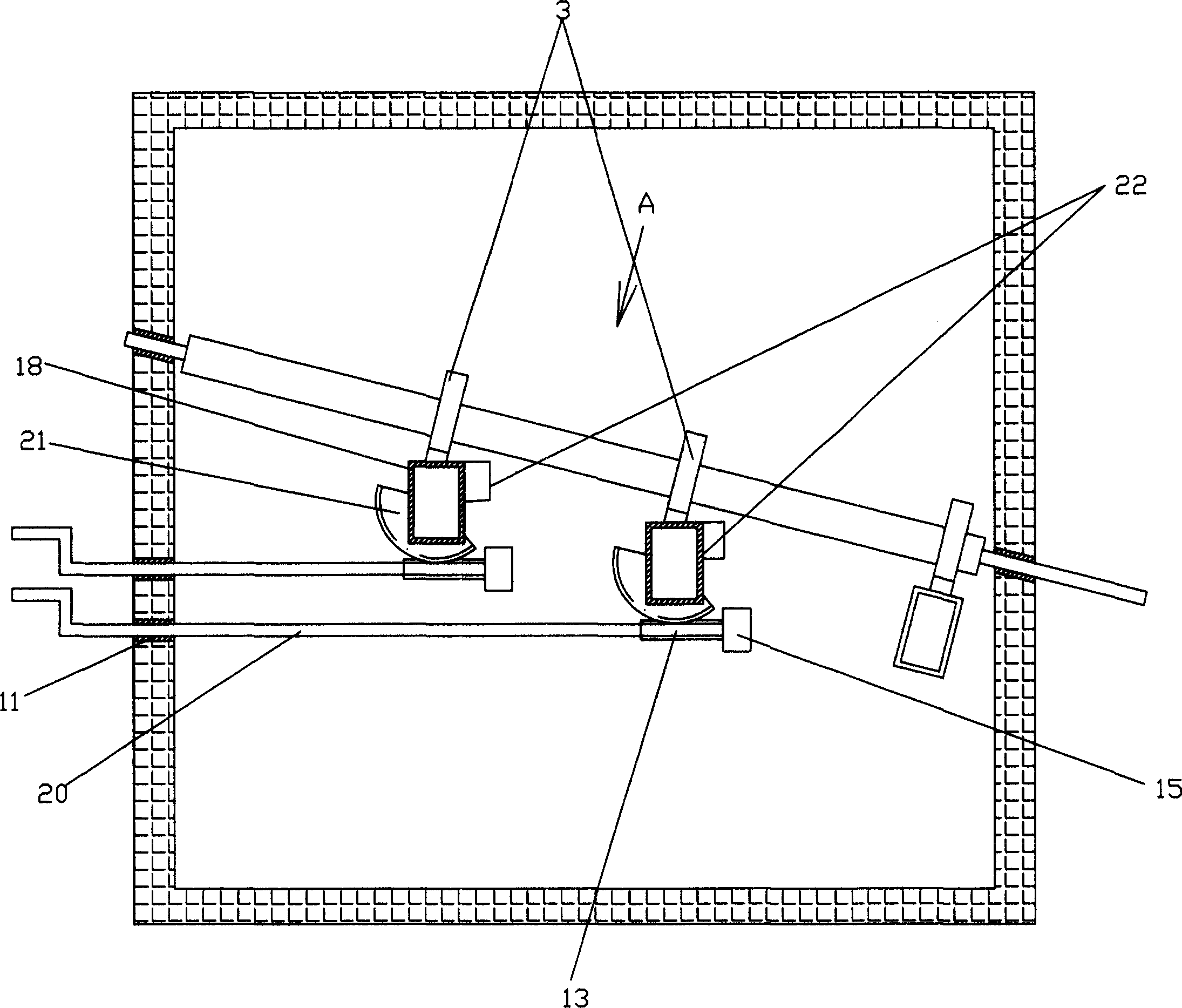

Inclined roller glass toughening furnace

A glass tempering and tilting technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased cost, restrictions on ultra-thin tempered glass, and increased cost of ceramic rollers, so as to improve work efficiency, The effect of making full use of the furnace space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] In Embodiment 2, the position adjustment screw 5 of the movable beam 18 can directly extend out of the top wall or bottom wall of the furnace body 1 at one end away from the ceramic roller table 2, and an operating handle is directly set at the end of the movable beam 18 extending out of the furnace body 1, or at its end. The end protruding from the furnace body 1 is then provided with a worm gear mechanism, and the operating handle is drawn out to one side of the furnace body 1 in the horizontal direction.

[0029] In addition, the operating handle 10 of Embodiments 1 to 3 can also be replaced with a conventional operating mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com