Deep draft dry-tree oil storage semisubmersible production platform

A production platform, semi-submersible technology, applied in the direction of floating buildings, etc., can solve problems such as the choice of riser form and the limitation of drilling and completion methods, the inability to use dry tree oil production equipment, and the poor movement performance. Design, small range of motion, the effect of reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

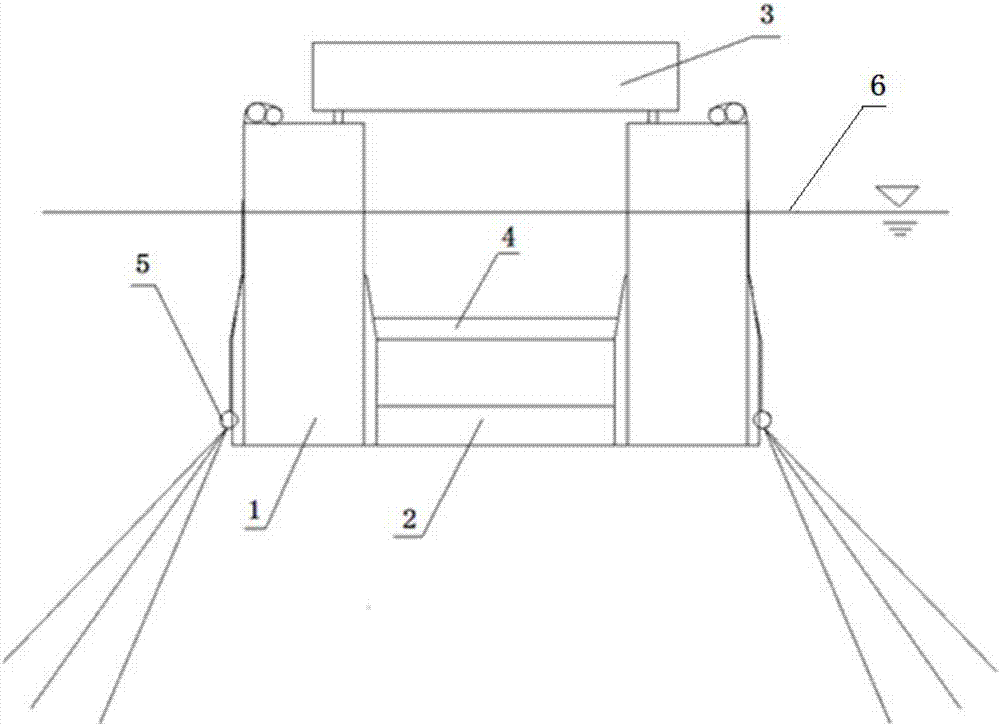

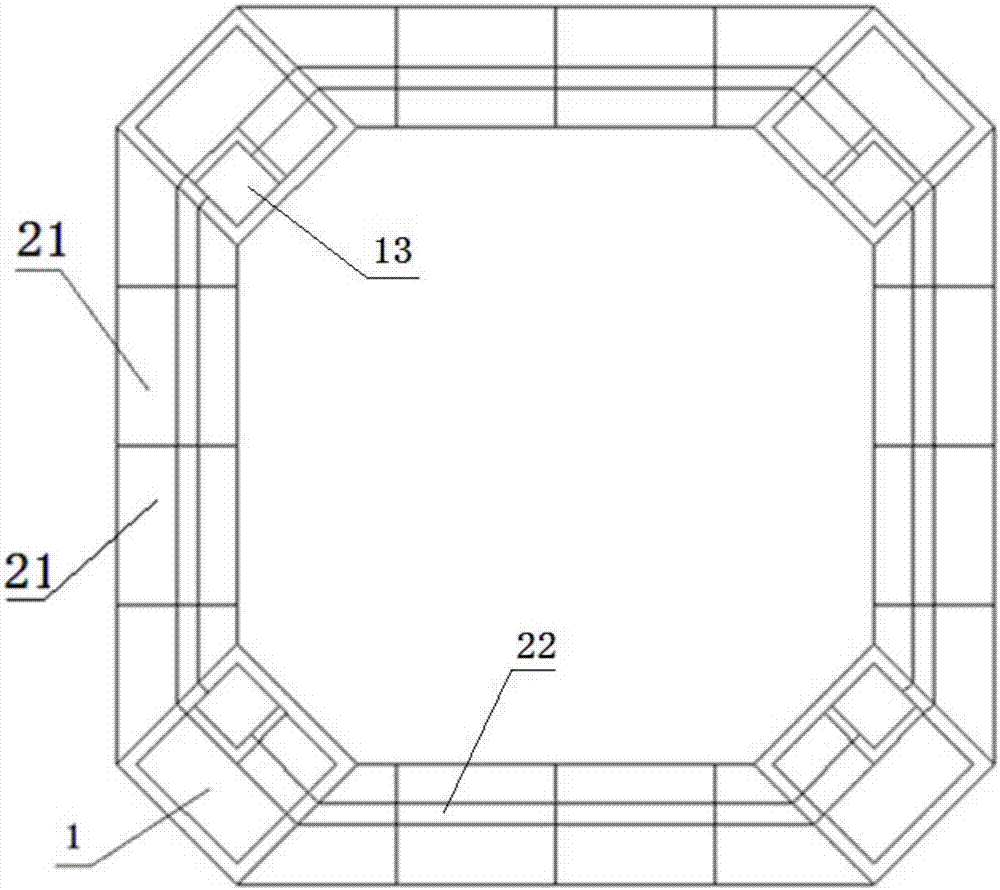

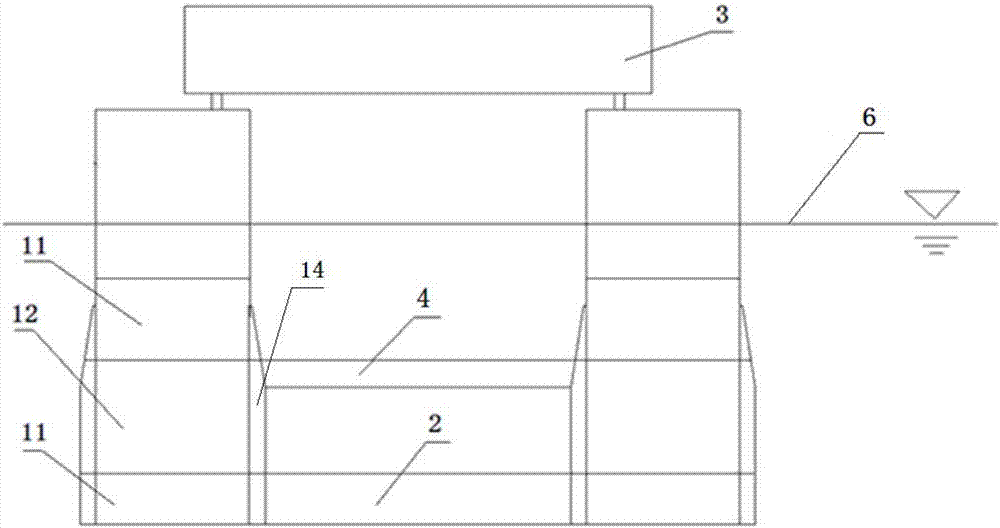

[0018] Such as Figure 1~3 As shown, the present invention provides a semi-submersible production platform for deep-draft dry tree oil storage, which includes a column 1, a buoyancy tank 2 and an upper module 3. Four buoyant tanks 2 are arranged around the bottom of the semi-submersible production platform, columns 1 are set at the corners of two adjacent buoyant tanks 2 , and the top surfaces of the four upright columns 1 support and connect the upper block 3 . Inside each column 1 is provided an oil tank 12 . In each column 1, ballast tanks 11 are respectively arranged up and down adjacent to the oil tank 12, and an equipment cabin is arranged at the top of each column 1, and an empty space is formed between the ballast tank 11 above the oil tank 12 and the equipment cabin, Ballast tanks 21 are also provided in each buoyancy tank 2 . When the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com