Foaming material filling box with reinforced layer and slurry leakage hole

A technology of foaming materials and slurry leakage holes, which is applied in the field of filling materials and foaming material inflatable boxes, and can solve problems such as unreasonable structural stress, inconvenient construction, and high cost of filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is realized in the following manner:

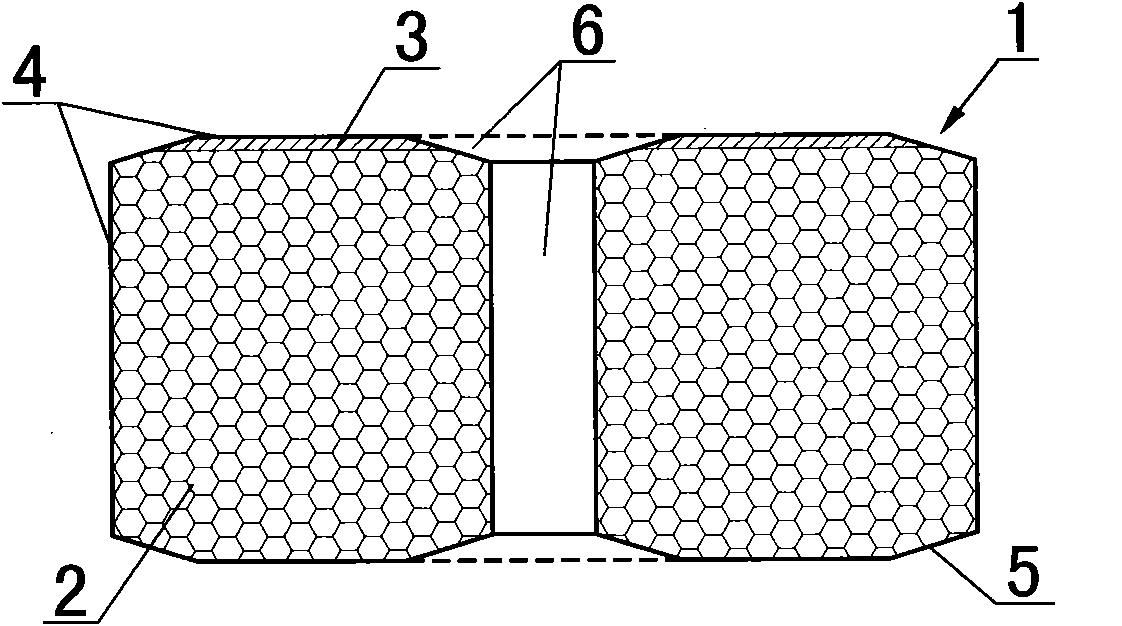

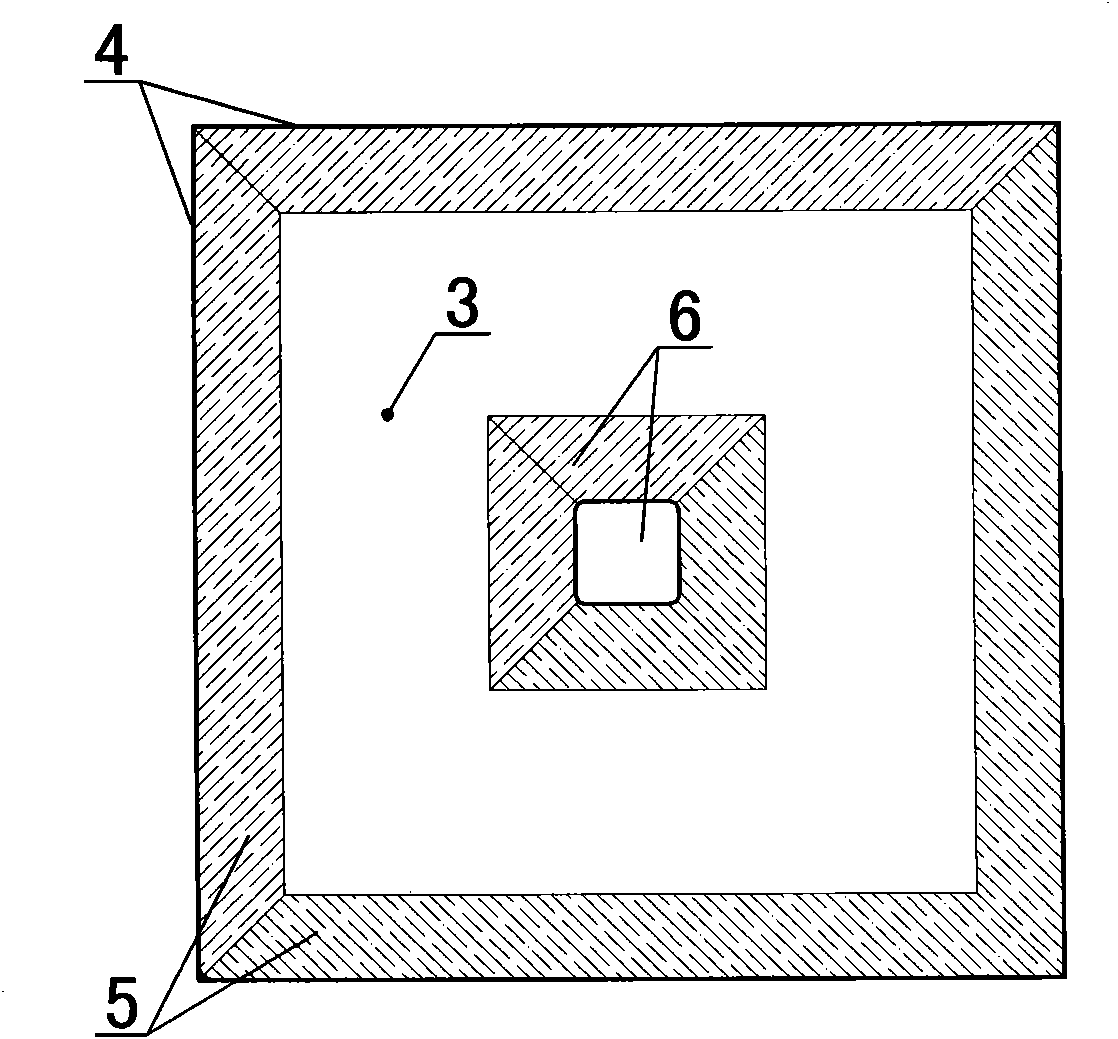

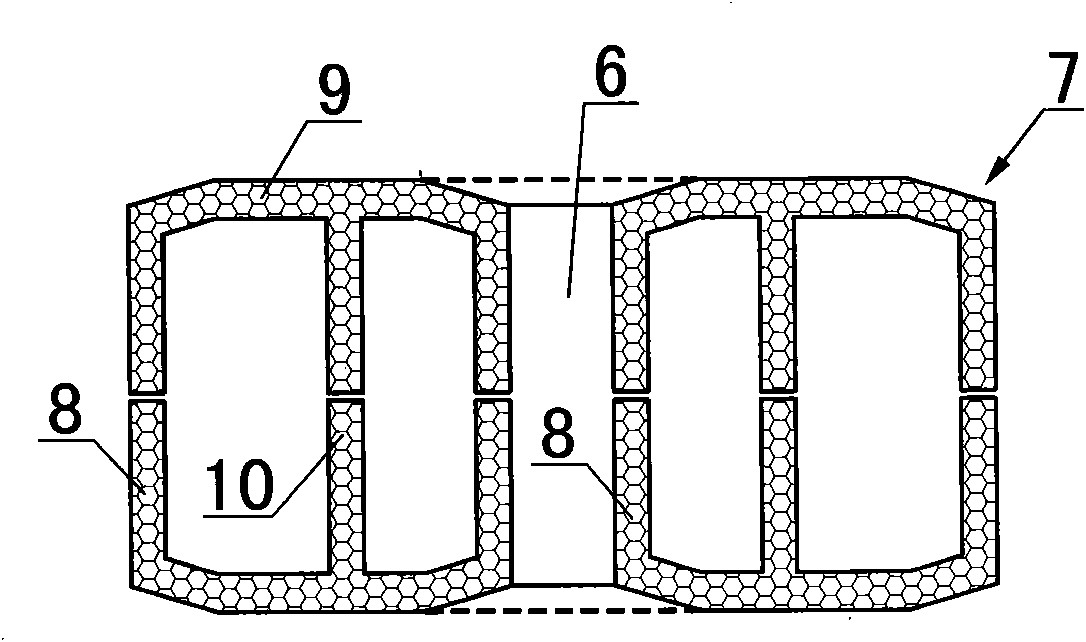

[0028] exist figure 1 , figure 2 In the shown embodiment, the main material of the body (2) of the filling box (1) is light foam material, and the planar shape of the filling box (1) is a rectangle, and the ratio of its long side to short side is less than or equal to 2, On the upper surface of the body (2), there is a hard reinforcement layer (3) with a planar shape that is annular, and an isolation layer (4) is arranged on the outer surface of the body, and the hard reinforcement layer (3) is located between the body (2) and the isolation layer (4). ), the upper and lower surfaces of the filling box (1) have cut corners or arc chamfers (5), and there is a vertical slurry leakage hole (6) in the middle of the filling box (1). The slurry leakage hole (6) The upper end of the upper end is a funnel shape with a big top and a small bottom, and the lower end of the slurry leakage hole (6) is an inverted funnel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com