Iron core, mold and method of forming and laminating the same

A technology for cores and molds, applied in the field of molds for forming and laminating said cores, capable of solving the problems of reduced machinability and complex process of E-shaped cores, etc., achieving increased magnetic flux density, improved machinability, and increased productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

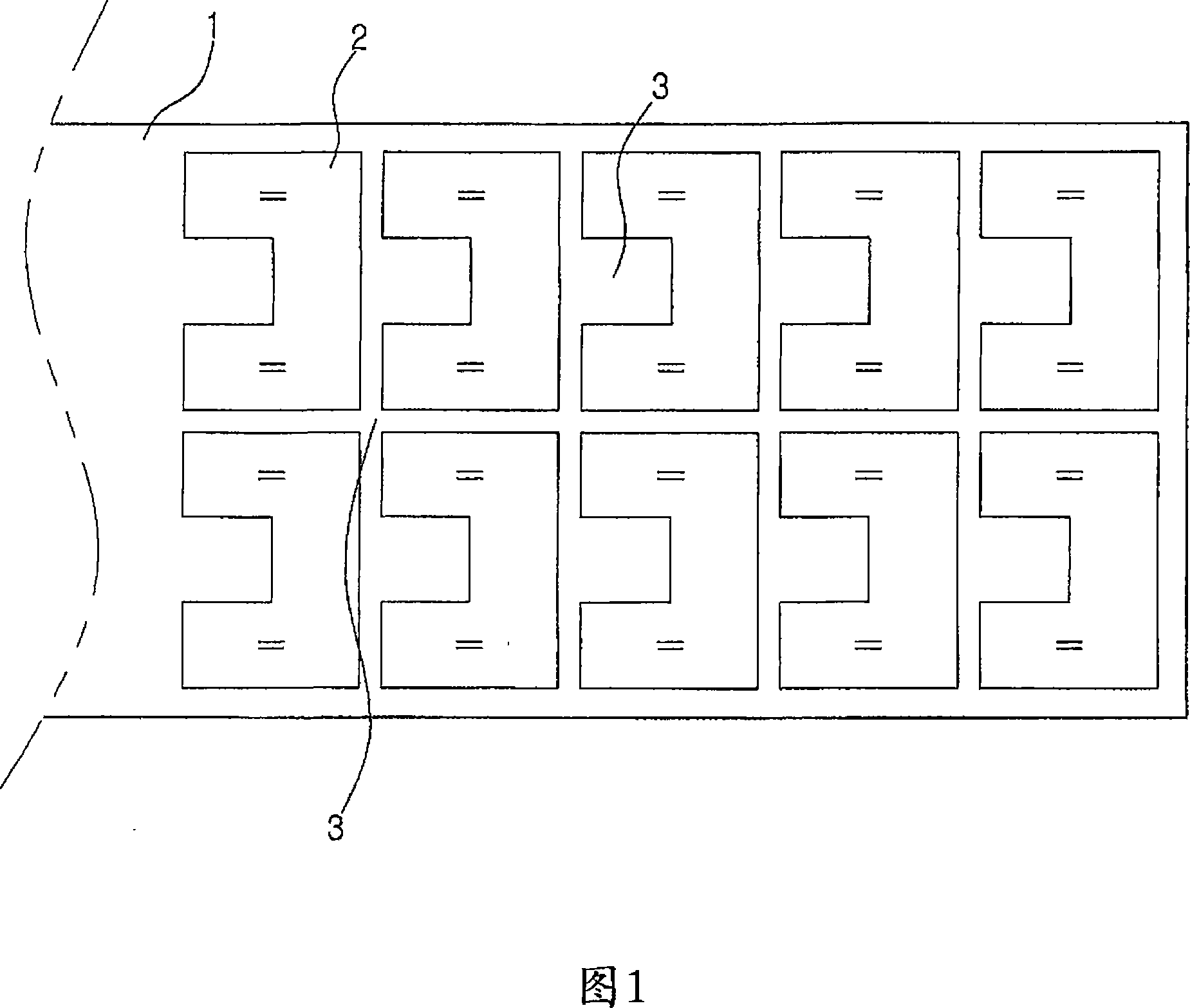

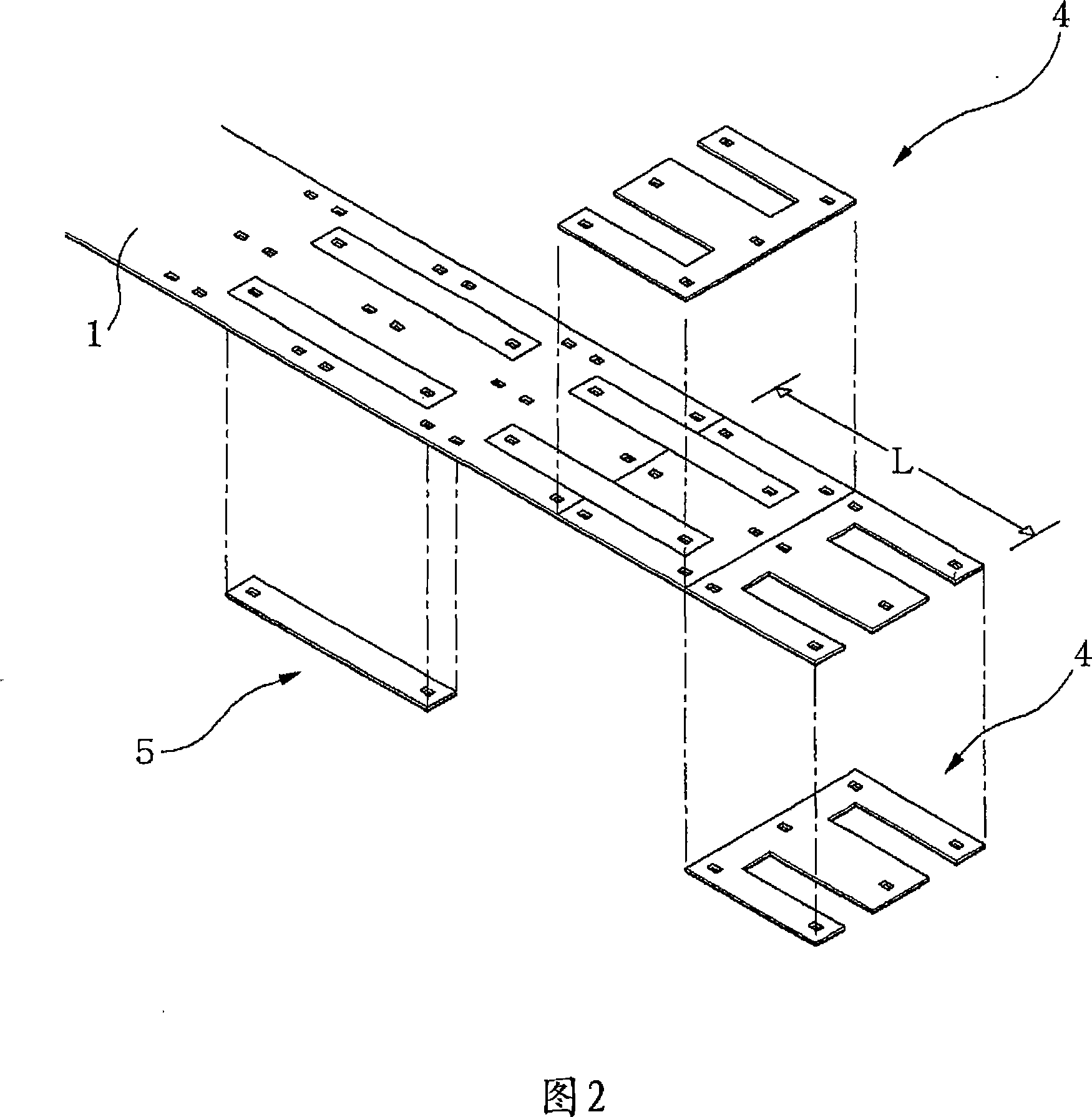

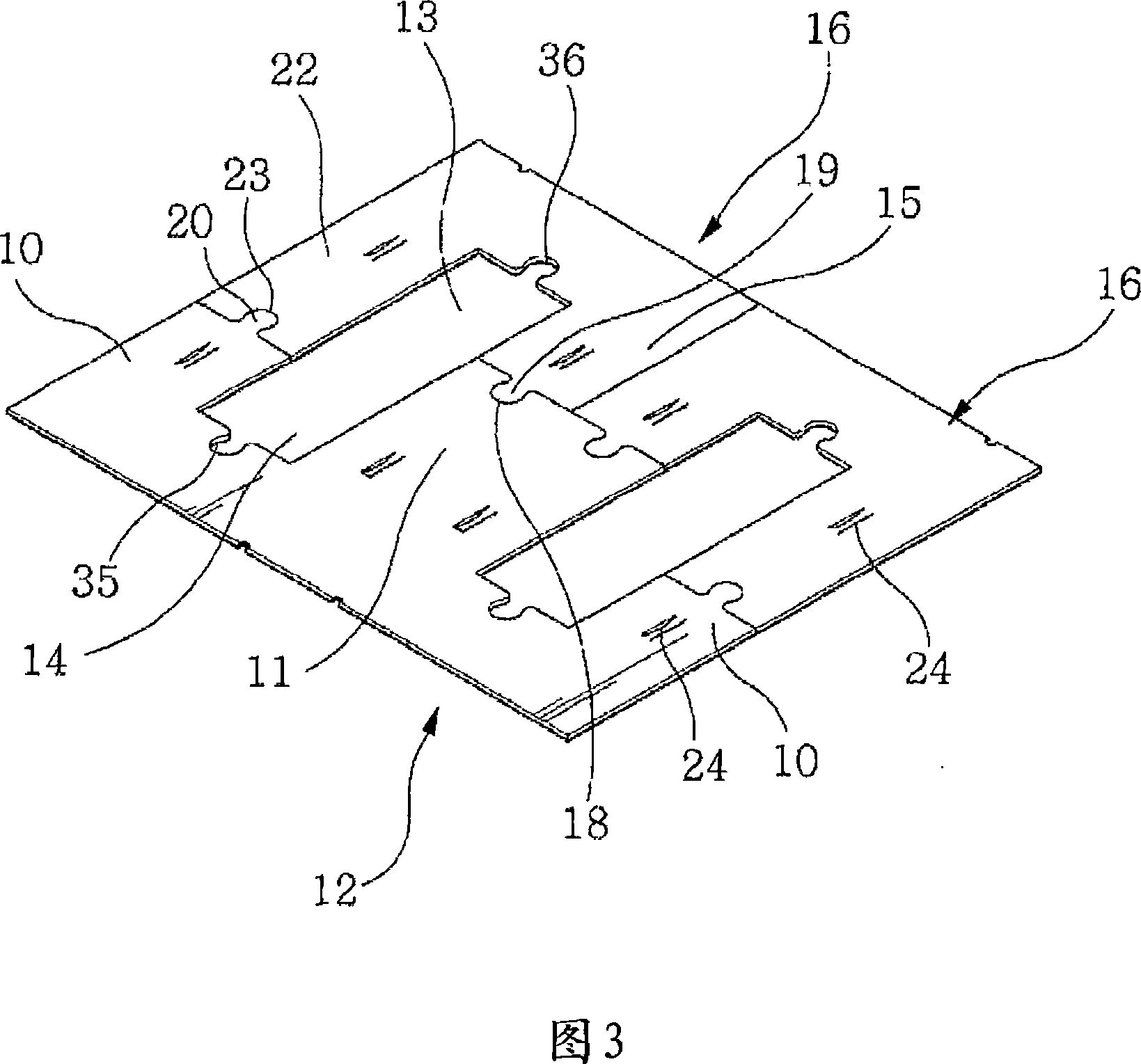

[0042]3 to 6, in the case of forming the iron core according to the present invention, by using a stamping die (not shown) from a silicon steel sheet 17 having a predetermined thickness (usually 0.5mm, or from 0.1mm to 0.35mm) At the same time, the E-shaped iron core 12 and a pair of -shaped iron cores 16 arranged on both sides of the E-shaped iron core 12 are stamped to prevent waste from being produced on the silicon steel sheet 17 .

[0043] The core includes an E-shaped core 12 having: side legs 10 formed in a symmetrical manner on both sides of the E-shaped core; and a bobbin formed between the side legs 10 and coupled to a coil wound thereon. and a stamped groove 14 formed between the side legs 10 and the central leg 11.

[0044] The core also includes a pair of -shaped iron cores 16, each -shaped iron core 16 has: a long leg 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com