Magnetic shoe moving device and conveying system

A technology of moving device and conveying system, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, and can solve the problems of slow moving efficiency and high cost of column-shaped magnetic tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

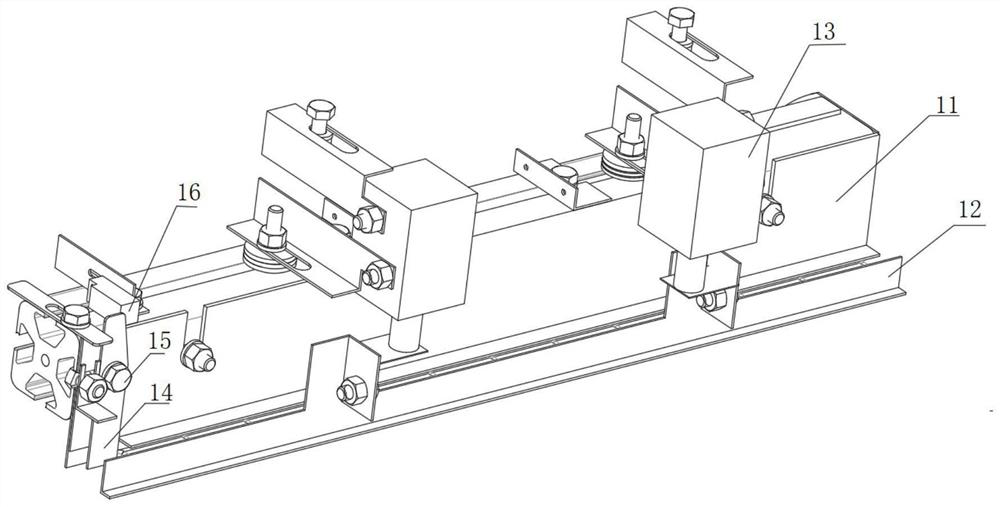

[0032] Such as figure 1As shown, a magnetic tile moving device includes a moving plate 11, a frame of the moving plate 11, and the moving plate 11 adopts a rectangular steel plate, which has high strength and long service life. The bottom of the moving plate 11 is opposite to the lifting plate 12 , and the lifting plate 12 is parallel to the moving plate 11 . A magnetic tile arrangement channel is formed between the lifting plate 12 and the moving plate 11. The setting of the lifting plate 12 is to form a channel with the moving plate 11. The two plates respectively form a limit effect on the magnetic tiles to ensure that the magnetic tiles are in the channel. Arrange neatly and orderly. The lifting plate 12 is connected with the lifting mechanism 13, and the moving plate 11 is connected with the driving mechanism. The end of the magnetic tile arrangement channel away from the conveying mechanism 2 is provided with a limit plate 14. The function of the limit plate 14 is to e...

Embodiment 2

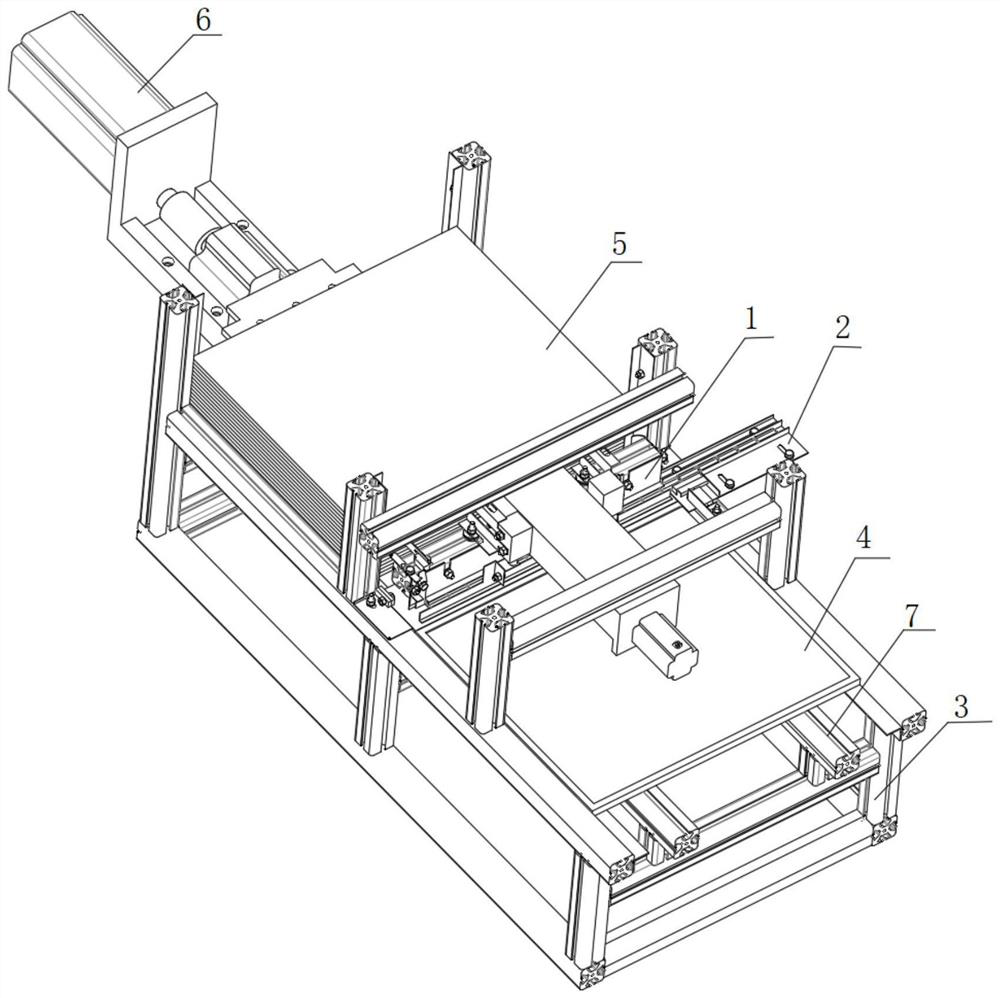

[0035] Such as figure 2 As shown, a magnetic tile conveying system includes the magnetic tile moving device 1 as described in the above embodiment, the magnetic tile moving device 1 is arranged on the frame 3, and the magnetic tile arrangement channel and the conveying mechanism in the magnetic tile moving device 1 2 connected. Specifically, the conveying mechanism 2 includes a transmission belt, which is connected to a power source, and the power source is electrically connected to a controller. Both sides of the transmission belt are provided with baffles, and the baffles are in contact with the magnetic tile arrangement channel. The distance between the two baffles is consistent with the distance of the magnetic tile arrangement channel, and the two baffles are respectively in contact with the moving plate 11 and the lifting plate 12 . The working principle of the conveying mechanism 2 is as follows: the transmission belt moves under the action of the power source, the ma...

Embodiment 3

[0038] Basically the same as embodiment 2, in order to further improve the automatic setting of the process, in this implementation, the bottom of the arrangement plate 4 is provided with a slide rail 7, and the bottom of the arrangement plate 4 is connected with the drive device 6, and the drive device 6 drives the arrangement plate 4 in the Move on slide rail 7. The driving device 6 can be a power source such as a motor or a cylinder. The bottom of the alignment plate 4 is connected with the driving device 6 to further improve the automatic setting of the whole process. After the row-shaped magnetic tiles on the arrangement plate 4 are full, the driving device 6 moves, and the arrangement plate 4 moves along the slide rail 7 and slides out of the frame 3 to perform the next operation, thereby reducing the labor intensity. At the same time, an inductor for inducting the magnetic tile is provided at the end of the arrangement plate 4 away from the magnetic tile moving device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com